Coal pillar type rock burst prevention and control method based on electric pulse

A technology of rock burst and electric pulse, which is applied in earthwork drilling, mining equipment, discharge machinery, etc., can solve the problems of insignificant pressure relief effect and heavy workload of drilling pressure relief, and achieve wide practical value and improve Single-hole gas drainage rate and the effect of reducing concentrated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

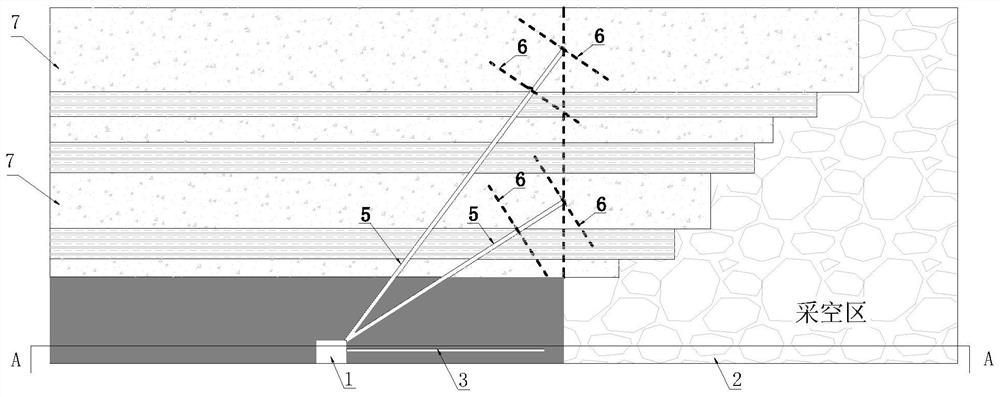

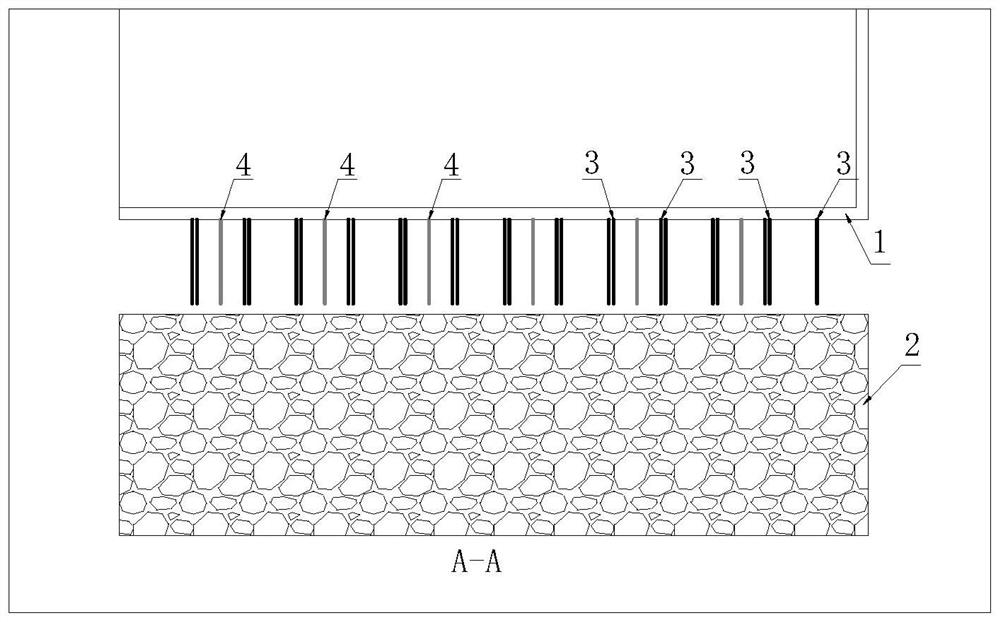

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0042] The present invention describes the implementation mode in detail by taking the prevention and control of rock burst of a coal pillar in a certain coal mine as an example. The buried depth of the 206 working face is 800m, the thickness of the coal seam is 12m, and there is no obvious structure inside the working face. There are 13m and 18m thick hard sandstone at the upper 8m and 30m of the coal seam. The inclined length of the working face is 200m, and the strike length is 1400m. The adjacent 205 working face has been mined. Due to the hard roof of the coal seam, the roof on one side of the goaf is not easy to collapse, and the overhanging roof caused serious def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com