Method for preventing rock burst by adopting high-pressure fracturing

A technology of rock burst and high pressure, applied in the field of high pressure fracturing prevention and control of rock burst, can solve problems such as difficulty in balanced pressure relief, limited space for implementation measures of rock burst prevention, etc., and achieve the effect of eliminating threats and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

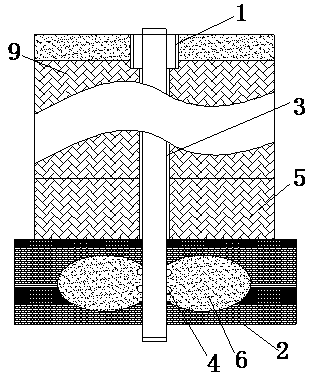

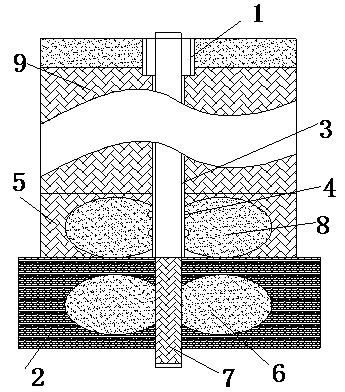

[0018] Such as figure 1 , 2 Shown: a method for preventing and controlling rockburst by high-pressure fracturing, characterized in that: its specific steps are as follows:

[0019] Step 1: use the drill bit to drill from the ground to the 15m of the stable bedrock layer 9, and run the ground casing 1 to fix the drilling, that is, cementing;

[0020] Step 2: use the drill bit to drill from the stable bedrock layer 9 to the bottom plate of the coal seam 2 to terminate at 20m, and run the shaft casing 3 to fix the drilling, that is, cementing;

[0021] Step 3: Drill perforations 4 around the casing 3 of the shaft with a perforating gun at the coal seam 2 and the conglomerate layer or the target rock formation 5;

[0022] Step 4: Using ground fracturing equipment, with a pressure of 40-60MPa, the water injection volume is 8-16m 3 / min inject water into the coal seam 2 through the perforation 4 to complete the fracturing of the coal seam 2, and form a coal seam pressure relief z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com