Novel rubber-coated sealing ring

A sealing ring and encapsulation technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of unable to meet the requirements of sealing, and achieve the effect of avoiding sealing failure, simple structure and improving elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

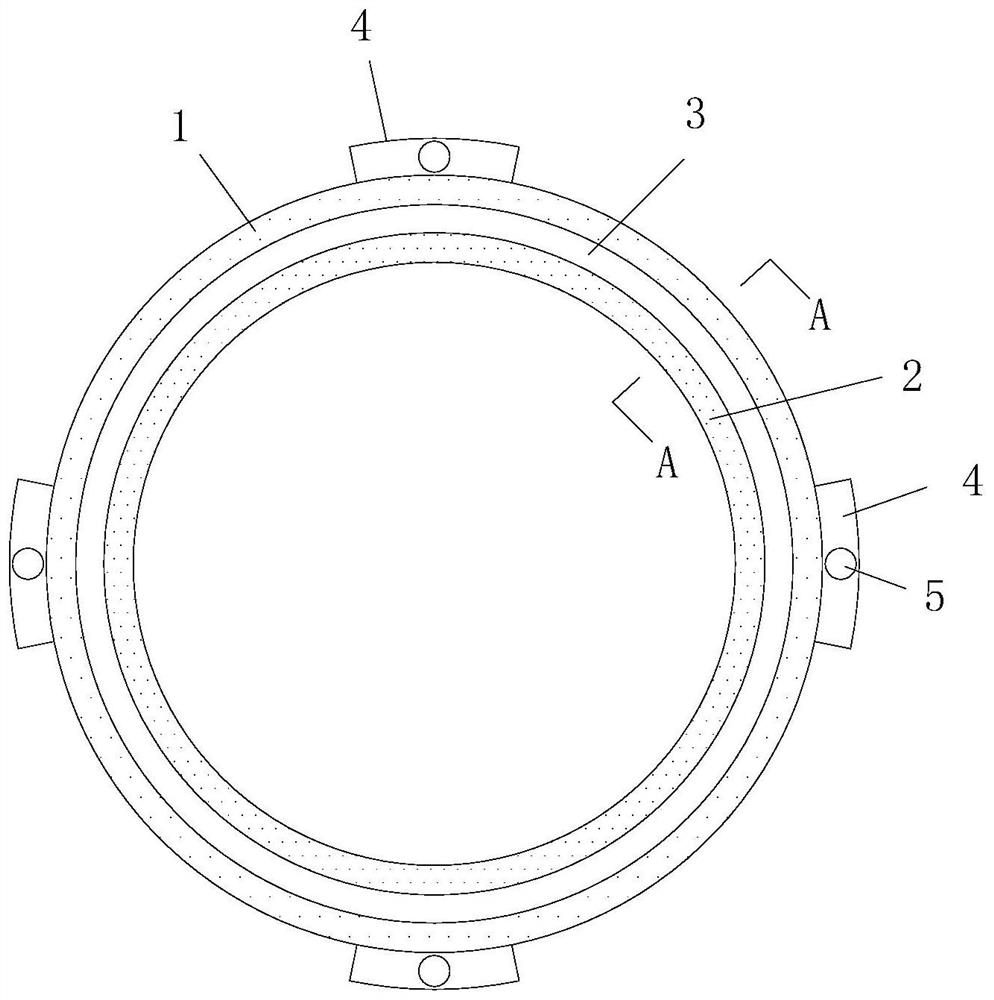

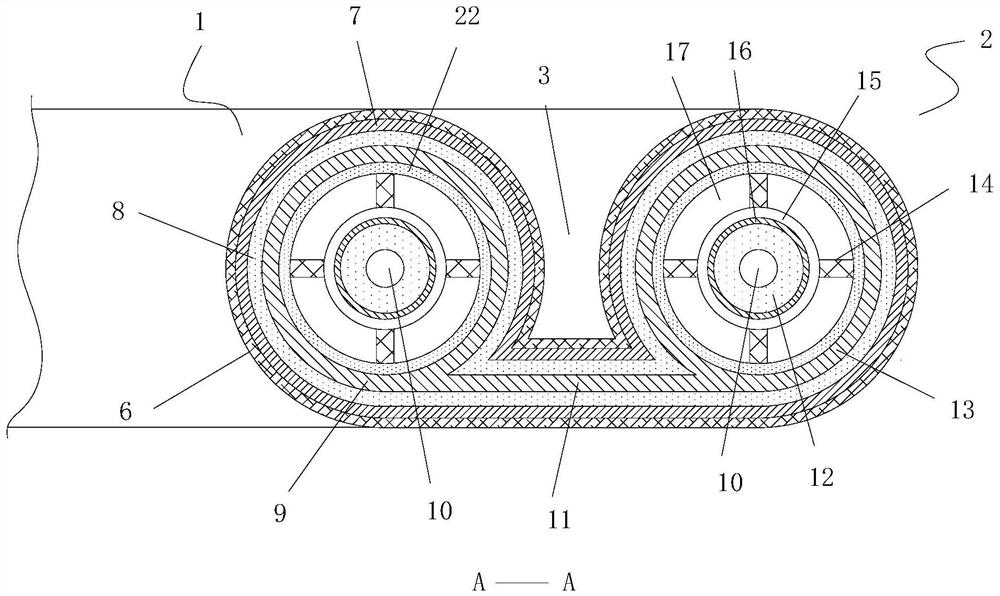

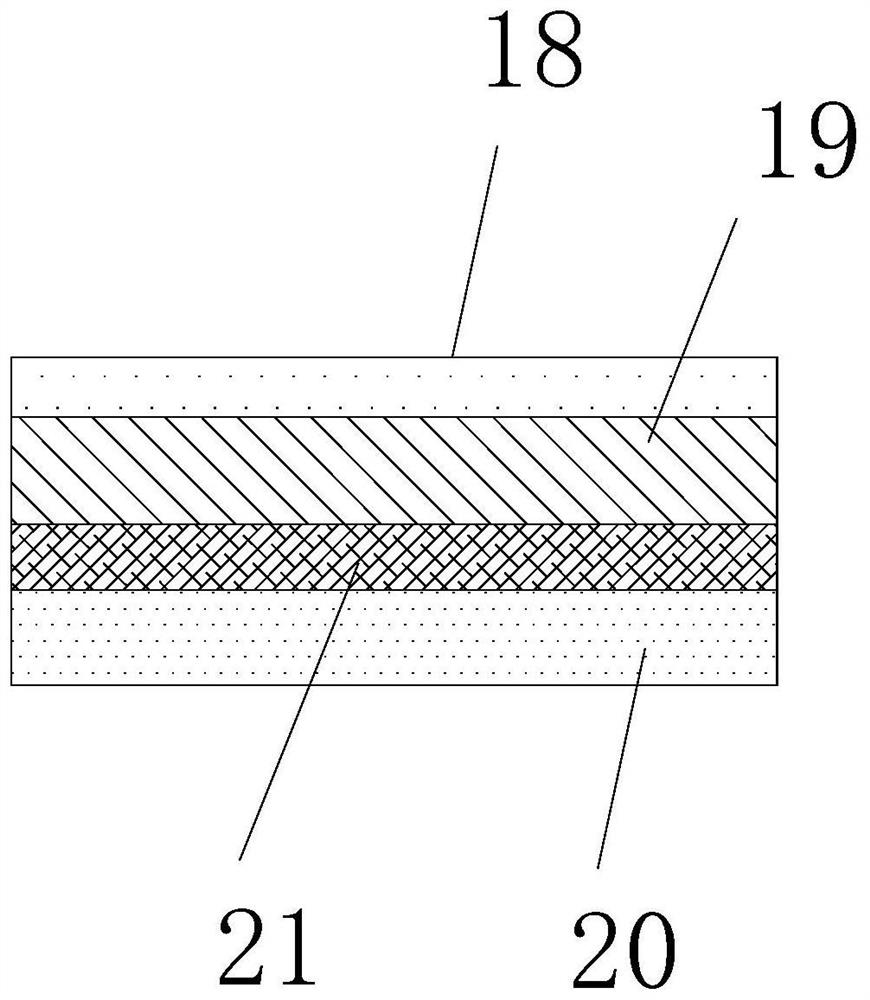

[0019] Example 1: See Figure 1~3 , a new type of rubberized sealing ring, including an outer ring 1 and an inner ring 2, the outer ring 1 includes a first elastic sleeve 9, the inner ring 2 includes a second elastic sleeve 13, and the first elastic An elastic rubber connection block 11 is integrally connected between the sleeve 9 and the second elastic sleeve 13, a sealing groove 3 is formed between the outer ring 1 and the inner ring 2, and the inside of the first elastic sleeve 9 The inside of the second elastic sleeve 13 is provided with a reinforcing sleeve 16, and the inside of the reinforcing sleeve 16 is provided with a plastic reinforcement ring 10, and the space between the plastic reinforcement ring 10 and the reinforcement sleeve 16 is filled with elastic foam Material 12, the inner wall of the first elastic sleeve 9 and the inner wall of the second elastic sleeve 13 are fixedly connected with the first elastic rubber layer 22, and the outer surface of the reinforc...

Embodiment 2

[0028] Example 2: see figure 1 , a new type of rubber-coated sealing ring, the difference from Example 1 is that the outer surface of the outer ring 1 is integrally connected with a number of anti-slip rubber blocks 4, and the anti-slip rubber blocks 4 are provided with positioning holes 4.

[0029] When in use, pass the fixing column at the seal through the positioning hole 4, and then pass the anti-slip rubber block 4 to prevent the position of the sealing ring from moving.

[0030] Further, the front and rear sides of the anti-slip rubber block 4 are integrally connected with several anti-slip protrusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com