Air and object surface sterilizer for laboratory

A laboratory and disinfection machine technology, applied in disinfection, air quality improvement, application and other directions, can solve problems such as poor disinfection effect, achieve the effect of strong practicability and avoid dead ends of disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

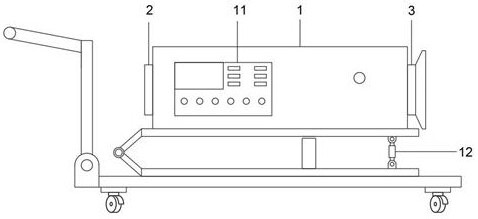

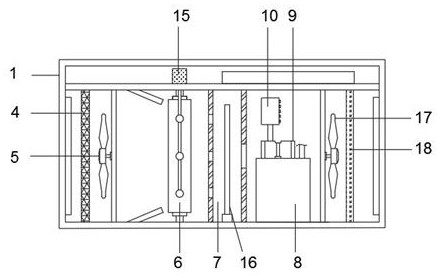

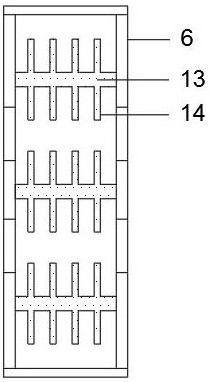

[0019] Example 1, see Figure 1-3 As shown, a laboratory air and surface disinfection machine includes a disinfection machine body 1, an air inlet 2 is fixedly connected to one side of the disinfection machine body 1, and an outlet port is fixedly connected to the other side of the disinfection machine body 1. Air port 3, the interior of the sterilizer body 1 is fixedly connected with a partition, the bottom of the partition is fixedly connected with a large-aperture filter 4, and one side of the large-aperture filter 4 is provided with an air intake fan 5, and the air intake One side of the fan 5 is provided with a drainage plate, and one side of the drainage plate is provided with an electrostatic precipitator chamber 6, and one side of the electrostatic precipitator chamber 6 is provided with a sterilization chamber 7, and one side of the sterilization chamber 7 is provided with a hypochlorous acid storage box 8. The top of the hypochlorous acid storage tank 8 is fixedly co...

Embodiment 2

[0025] Example 2: See figure 2 , The difference between this embodiment and Embodiment 1 is that: one side of the hypochlorous acid storage tank 8 is provided with an air outlet fan 17, and one side of the air outlet fan 17 is provided with a fine particle filter screen 18, and the fine particle filter screen 18 It is a HEPA filter screen, and by setting the fine particle filter screen 18, the filter screen can intercept and filter the tiny particles that are not completely separated by electrolysis, so as to avoid re-discharging into the air and causing pollution.

[0026] When the present invention is in use, the disinfection angle of the disinfection machine body 1 can be controlled by setting the electric telescopic rod 12, which facilitates the sterilization and disinfection of various positions in the laboratory, avoids the occurrence of disinfection dead ends, and has strong practicability. By setting the electrostatic dust removal chamber 6 Combined with the high-volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com