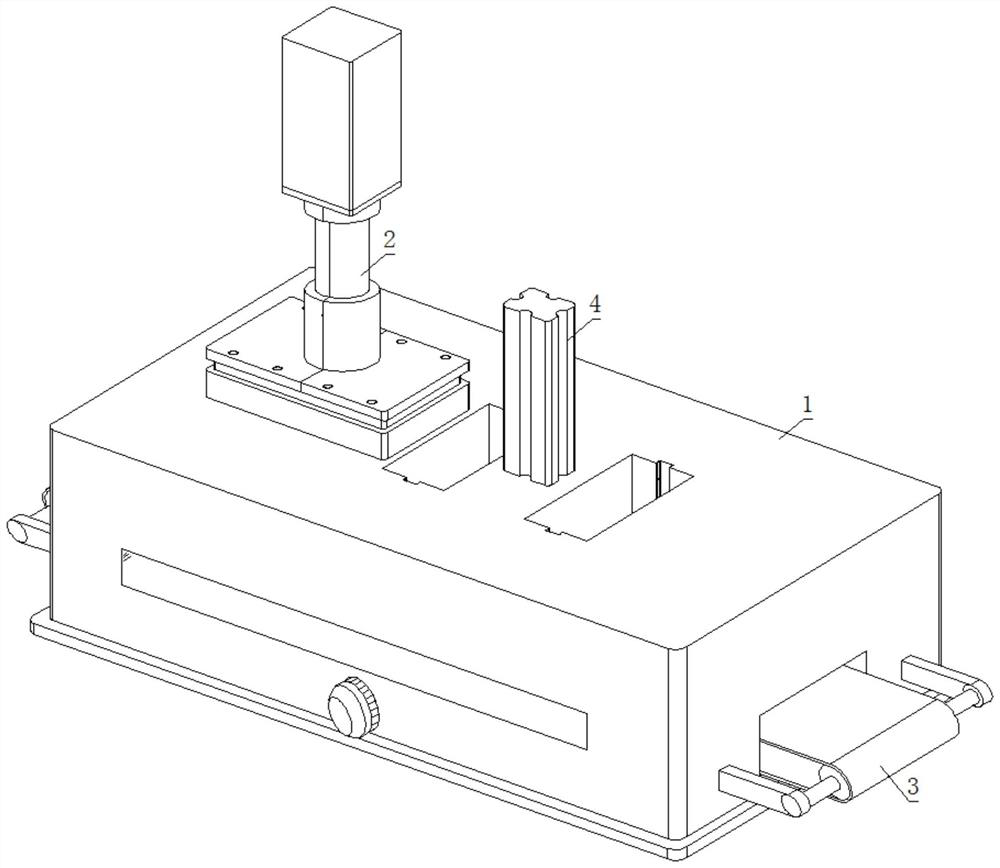

Crack detection device and method for preventing secondary damage and used for touch screen failure detection

A secondary damage and detection device technology, which is applied in the direction of cleaning methods using tools, measuring devices, and cleaning with electrostatic methods, can solve the problems of easy cost loss, secondary damage to the touch screen, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

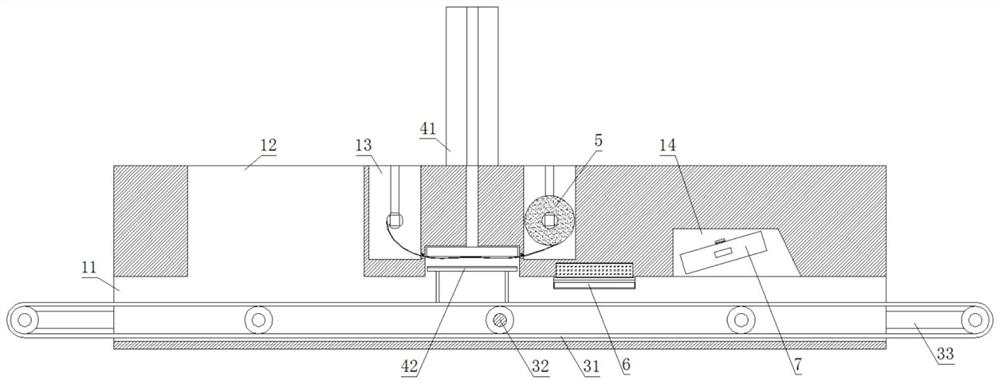

[0056] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, an implementation method of a crack detection device for preventing secondary damage for touch screen failure detection, including the following steps:

[0057] Step 1: The film ring 53 is set in a loose state at the lower end of the cutting frame 414. When the touch screen moves to the right below the film cutting assembly 4, the electric cylinder main body 411 is started at this time, and the output end of the electric cylinder main body 411 is It will drive the pressing rack block 412, the extruding film sticking plate 413 and the cutting frame 414 to move downward together;

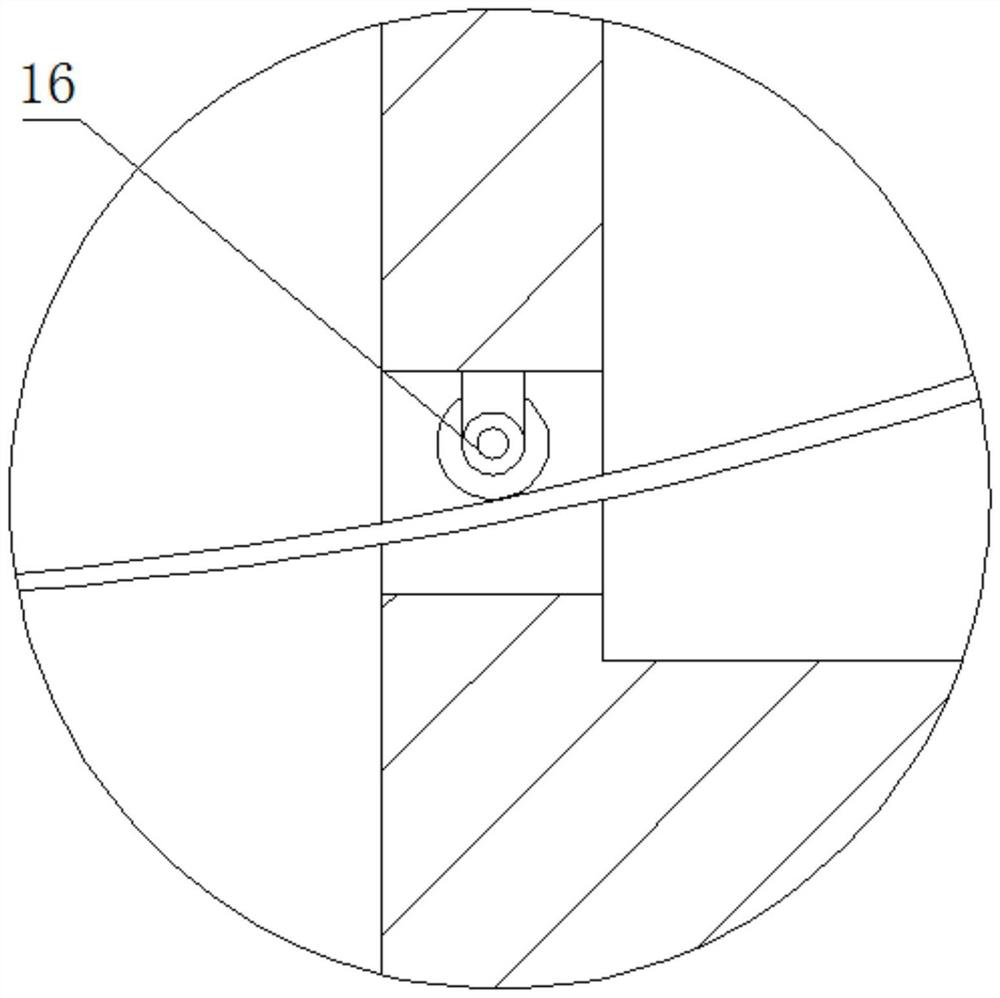

[0058] Step 2: At this time, driven by the tooth block 4122, the one-way drive gear 541 can be driven to rotate counterclockwise, and at this time, under the action of the one-way stop block 5415, the clamping block 5413 can drive the raised block 5422 Rotate, thereby drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com