Device and method for testing interface friction performance of clay-based material

A testing device and interface friction technology, which is applied to measuring devices, analyzing materials, and adopting mechanical devices, can solve problems such as large measurement errors, failure to consider factors of formation consolidation, and failure to observe formation disturbances, so as to control soil disturbances , good effect of soil disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

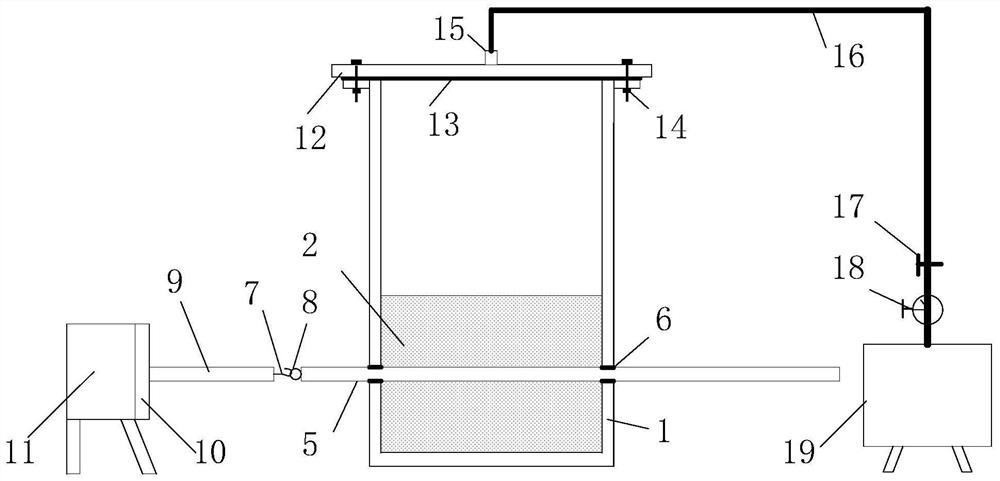

[0039] refer to figure 1 Shown, a kind of clay-based material interface friction performance testing device of the present invention comprises:

[0040] The test box 1 is used to fill the soil sample or clay-based material 2, and the side wall of the test box 1 is provided with an in-out through hole, and the soil sample or clay-based material 2 filled in the test box 1 is higher than the in-out hole. hole;

[0041] The test slide plate 5 is inserted into the in-out through hole and can slide along the in-out through hole;

[0042] The transmission test device is connected with one end of the test slide 5, and the transmission test pulls the test slide 5 to slide along the in-out through hole, and measures the required pulling force when pulling the test slide 5 to slide;

[0043] An air pressure device communicated with the test box 1 to apply pressure to the soil sample or clay-based material filled in the test box 1;

[0044] In the clay-based material interface friction p...

Embodiment 2

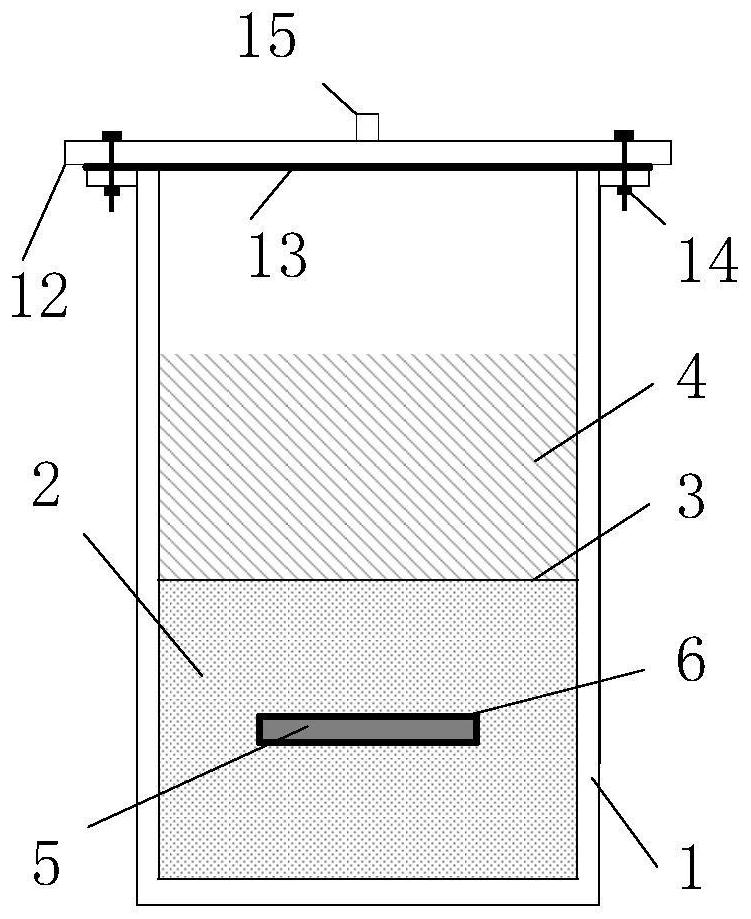

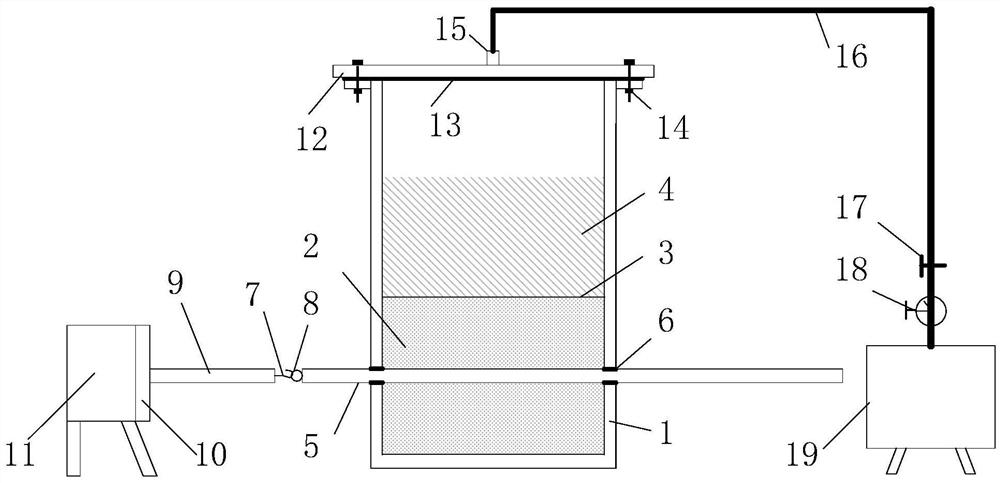

[0052] refer to image 3 As shown, on the basis of the above-mentioned embodiment 1, in order to make the pressure applied by the air compressor uniformly act on the soil sample or clay-based material 2, so as to truly simulate the consolidation pressure of the buried deep soil, the The test box 1 is also filled with a watertight layer 4, the watertight layer 4 is arranged above the soil sample or clay-based material 2, the air pressure device applies pressure to the watertight layer 4, and the watertight layer 4 and the soil An anti-seepage film 3 is arranged between the samples or clay-based materials 2, and the edge of the anti-seepage film 3 is attached to the inner wall of the box, and the pressure is applied to the watertight layer 4 by the air pressure device to make the applied pressure evenly distributed On the soil sample or clay-based material 2 , water is prevented from entering into the soil sample or clay-based material 2 through the anti-seepage film 3 , and the...

Embodiment 3

[0054] refer to Figure 4 As shown, a kind of clay-based material interface friction performance testing method of the present invention adopts the testing device of above-mentioned embodiment 1, comprises the following steps:

[0055] S1. Insert the test slide 5 into the test box 1, start the air pressure device, and test the air tightness in the test box 1. In order to ensure that the air pressure device can apply pressure to the test box 1, it is necessary to test the air Check the airtightness. If there is an air leak in the test box 1, the pressure applied by the air pressure device is inaccurate and unstable. The airtightness test in this embodiment is mainly aimed at the connection between the box body and the sealing cover 12. The detection between, and the airtightness detection to inserting the in and out through hole place of test slide plate 5;

[0056] S2, start the transmission test device, measure the pulling force F0 required for pulling the test slide 5 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com