Shockproof hammer defect detection method, device and equipment and storage medium

A defect detection and anti-vibration hammer technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve problems such as low detection accuracy, inability to meet the needs of transmission line inspection, meet accuracy requirements, and improve richness. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

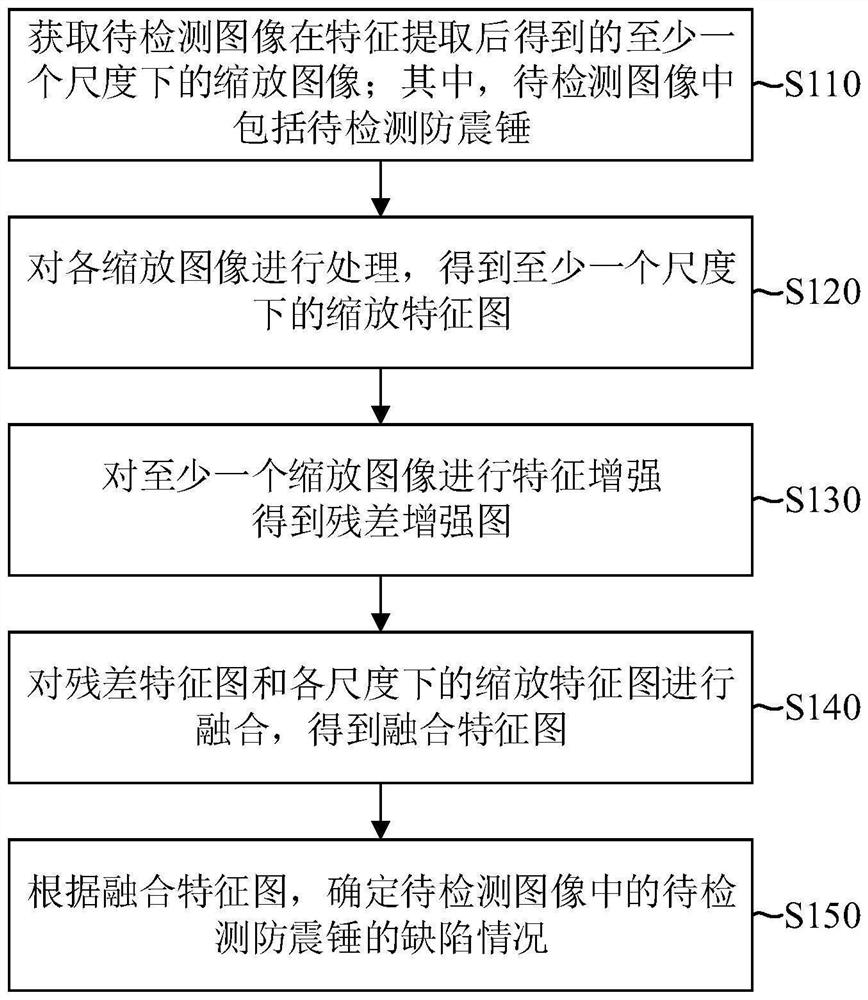

[0032] figure 1 It is a flow chart of a method for detecting a defect in an anti-vibration hammer provided in Embodiment 1 of the present application. The embodiments of the present application are applicable to the detection of anti-vibration hammers of power transmission lines. The method can be implemented by a device for detecting vibration-proof hammer defects. The device can be implemented by software and / or hardware, and is specifically configured in electronic equipment.

[0033] refer to figure 1 A method for detecting a defect of a shockproof hammer specifically includes the following steps:

[0034] S110. Acquire a zoomed image in at least one scale obtained after feature extraction of the image to be detected; wherein, the image to be detected includes an anti-vibration hammer to be detected.

[0035] Wherein, the image to be detected is an image in which defect detection needs to be performed on the anti-vibration hammer to be detected. Feature extraction can b...

Embodiment 2

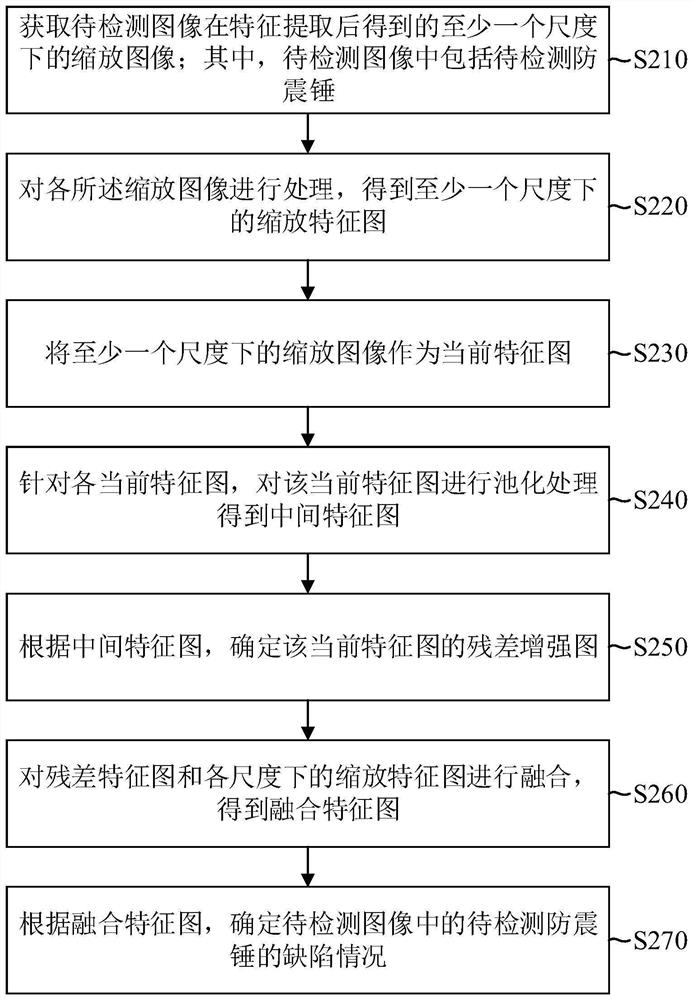

[0054] figure 2 It is a flow chart of a method for detecting a defect of an anti-vibration hammer provided in Embodiment 2 of the present application. The embodiment of the present application refines the acquisition operation of the residual enhancement map on the basis of the technical solutions of the foregoing embodiments, so as to improve the accuracy of the defect detection of the anti-vibration hammer.

[0055] refer to figure 2 A method for detecting a defect of a shockproof hammer specifically includes the following steps:

[0056] S210. Acquire a scaled image of at least one scale of the image to be detected after feature extraction; wherein, the image to be detected includes an anti-vibration hammer to be detected.

[0057] S220. Process each scaled image to obtain a scaled feature map in at least one scale.

[0058] S230. Use the scaled image in at least one scale as the current feature map.

[0059] The scaled feature map at least one scale is used as the cu...

Embodiment 3

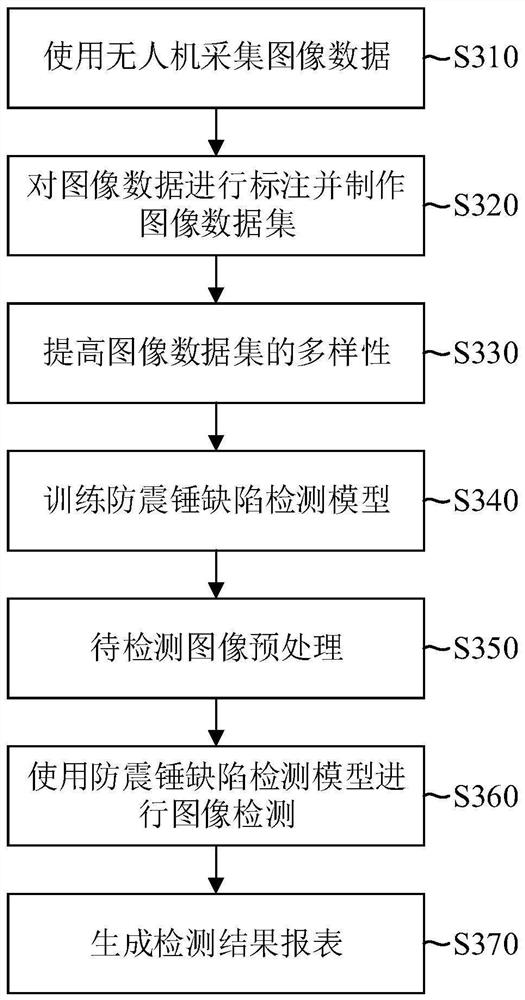

[0078] Figure 3A It is a flowchart of defect detection of anti-vibration hammer provided in Embodiment 3 of the present application. The embodiment of the present application is a preferred embodiment provided on the basis of the foregoing embodiments, and is applied to an electronic device. refer to Figure 3A , the method specifically includes:

[0079] S310. Use unmanned to collect image data.

[0080] The anti-vibration hammer of the field transmission line is captured by a remote-controlled drone.

[0081] S320. Mark the image data and create an image data set.

[0082] Using the method of manual labeling to classify and label the collected images of anti-vibration hammers, two classifications can be performed first, that is, the collected images are marked as "with anti-vibration hammers" and "without anti-vibration hammers", and then from "with anti-vibration hammers" For example, it can be divided into: anti-vibration hammer is normal, anti-vibration hammer is da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com