Process and system for producing ethylene carbonate and/or ethylene glycol

A technology of ethylene carbonate and ethylene glycol, applied in chemical instruments and methods, separation methods, sustainable manufacturing/processing, etc., can solve problems such as chloride stress corrosion, inorganic chloride accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

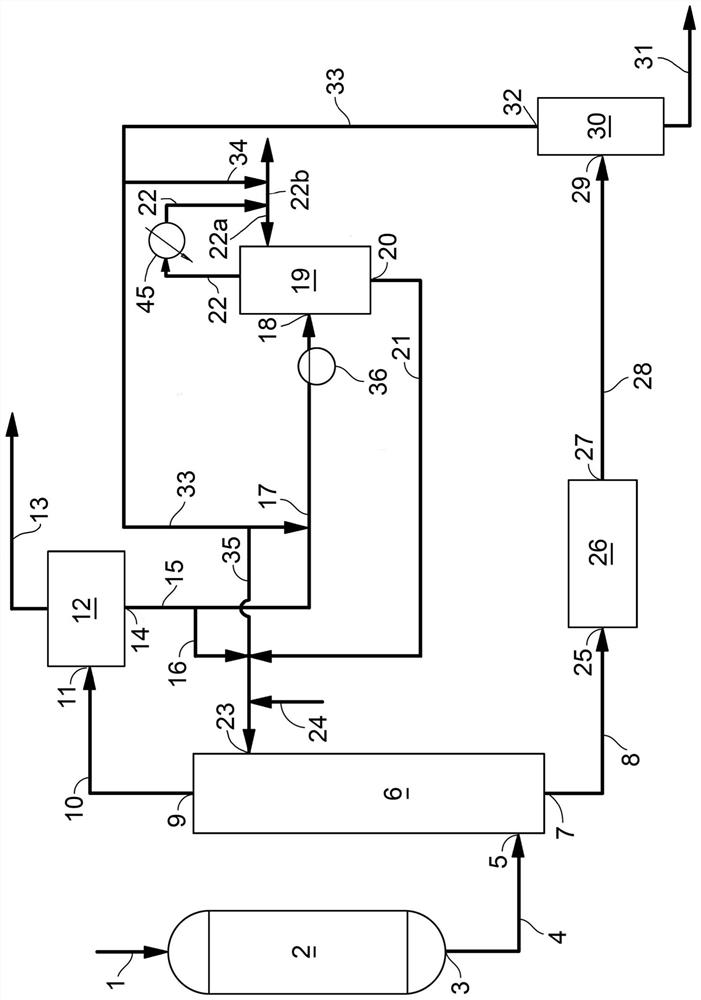

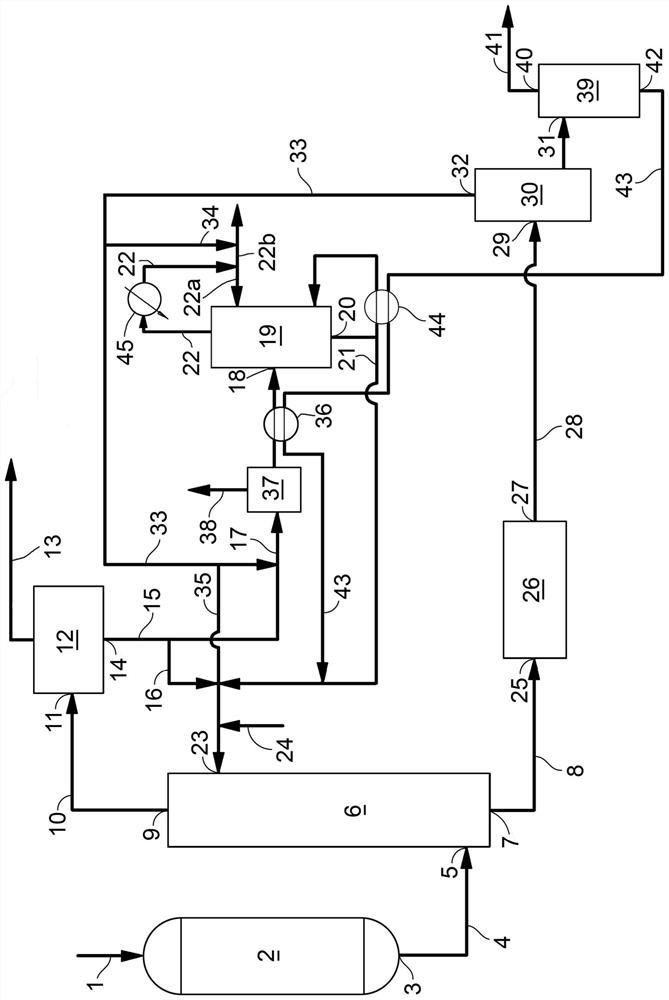

Image

Examples

Embodiment Construction

[0025] As described below, the process of the present invention comprises various steps. The process may contain one or more intermediate steps between these steps. Furthermore, the process may comprise one or more additional steps before the first mentioned step and / or after the last mentioned step.

[0026] Although the methods and systems of the present invention and the mixtures or streams used in said methods use the terms "comprising", "containing" or "including" one or more of the various described steps and components, but they may also "consist essentially of" or "consist of" one or more of the various described steps and components ".

[0027] In the context of the present invention, where a mixture, stream or catalyst comprises two or more components, these components are selected in a total amount not exceeding 100%.

[0028] In this specification, "substantially free" means that no detectable amount of said component is present in the catalyst or composition. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com