Process for preparing 2, 4-dinitro-6-chloroaniline by sulfuric acid method

A technology of dinitro and chloroaniline, which is applied in the field of chemical reaction preparation, can solve the problems of uneven chlorination, affect the quality of reaction products, slow chlorination speed, etc., and achieve the improvement effect, better stirring effect and selectivity. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

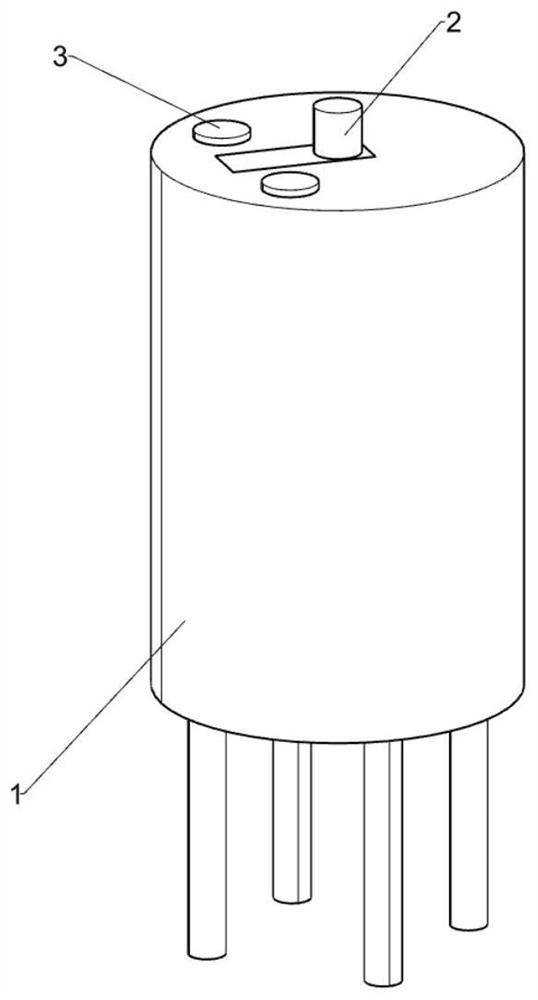

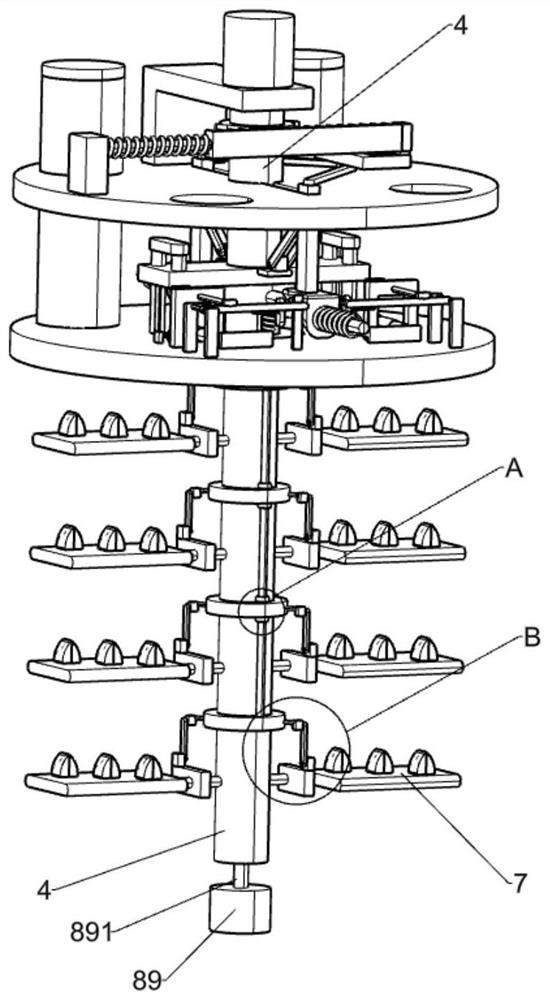

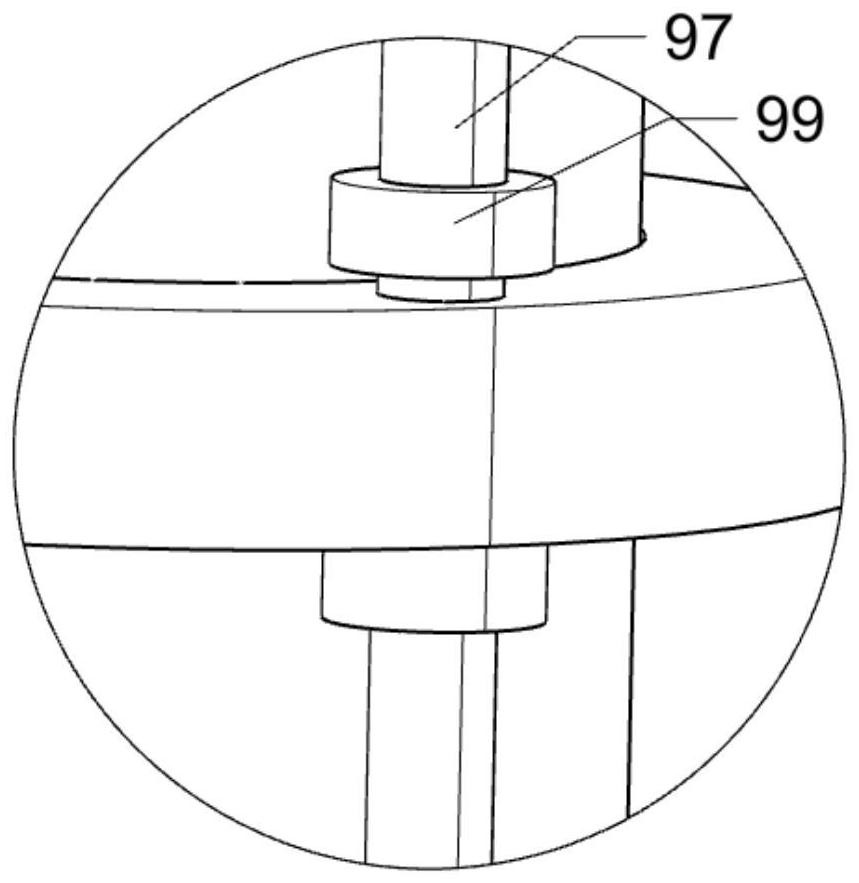

[0050] like Figure 1-25 As shown, a process for preparing 2,4-dinitro-6-chloroaniline by a sulfuric acid method includes the following steps: using a stirring device to process and react the reaction raw materials, discharging and suction filtration after the reaction is completed; the stirring The device includes a mixing bucket 1, a motor 2 fixed on the mixing bucket 1, a first bracket 21 fixed on the mixing bucket 1 for supporting the motor 2, an electric plate 3 arranged on the mixing bucket 1, and a motor 2 The speed-appropriate structure 6 below, the control structure 5 located under the speed-appropriate structure 6, the stirring shaft 4 connected to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com