A kind of preparation method of xanthine

A technology of xanthine and guanine, applied in the field of preparation of purine drug intermediates, can solve the problems of cumbersome production process steps, difficult waste disposal and high safety risk, and achieves inhibition of side reactions, high molar yield and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

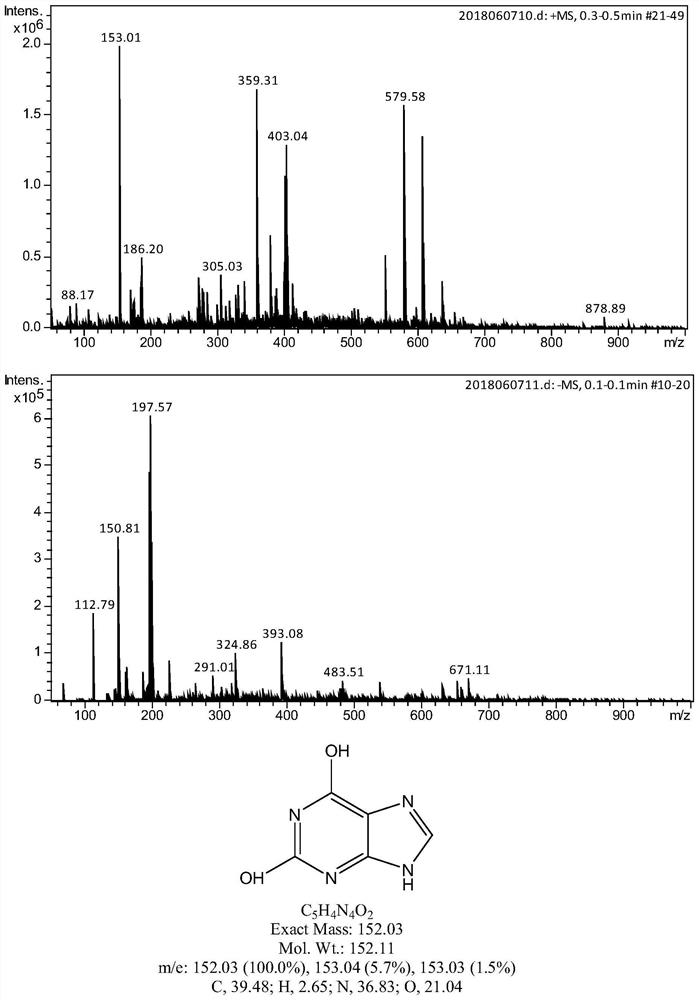

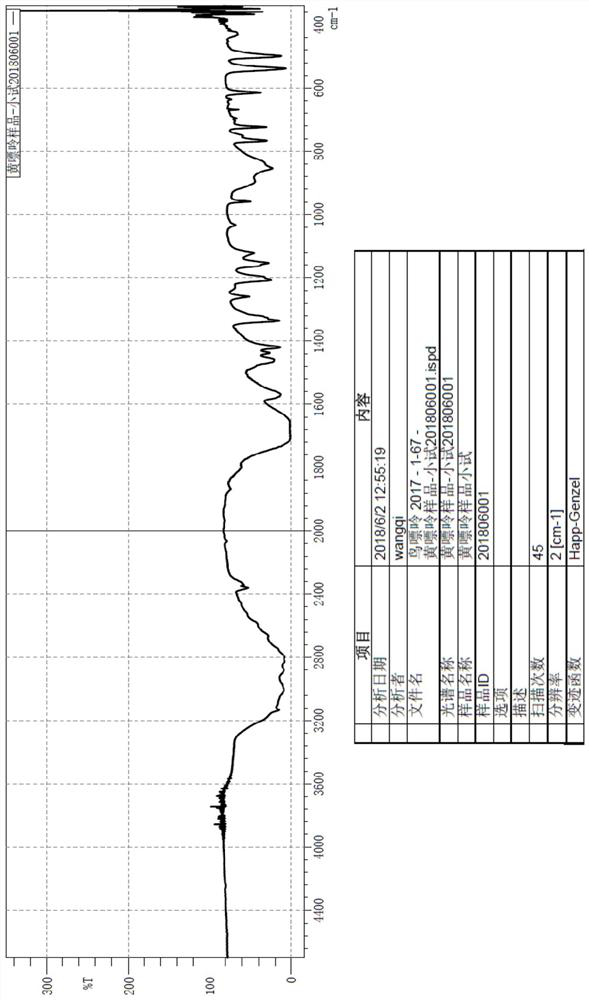

Image

Examples

Embodiment 1

[0053] 200g of purified water, 66g of 33% concentrated hydrochloric acid, and 30g of guanine (0.1985mol) were sequentially put into a 500mL three-necked flask, stirred, heated to 85°C and stirred for 0.5h. Then, 50 g of 40% sodium nitrite aqueous solution (0.2899 mol) was slowly added dropwise at 20°C.

[0054] After dropping, raise the temperature to 45°C to continue the reaction for 2 hours, cool down to 15°C, press filter, wash, and the filtrate can be applied to the next batch of "diazotization" feeding. 56 g of AH01 were obtained.

[0055] Put 250g of purified water and 56g of AH01 into a 500mL enamel reaction kettle, start stirring, and heat up to 80°C for 2.0 hours of hydrolysis reaction. After the reaction was completed, 65 g of 27% ammonia water (0.5007 mol) was added. Heat up to 80°C to dissolve, add 2g of activated carbon to decolorize for 0.5h, press filter while hot, and cool the filtrate to 25°C to grow crystals for 1h. Suction filter to dryness, wash the filt...

Embodiment 2

[0058] Put 250g of the above batch of AH01 filtrate, 25g of 33% concentrated hydrochloric acid, and 30g of guanine (0.1985mol) into a 500mL flask in turn, stir, and raise the temperature to 85°C to stir for 0.5h. Then, 40 g of 40% sodium nitrite aqueous solution (0.2319 mol) was slowly added dropwise at 20°C.

[0059] After dropping, raise the temperature to 45°C to continue the reaction for 2 hours, cool down to 15°C, press filter, wash, and the filtrate can be applied to the next batch of "diazotization" feeding. 57 g of AH01 were obtained.

[0060] Put 250g of purified water and 57g of AH01 into a 500mL flask, start stirring, and heat up to 80°C for 2.0 hours of hydrolysis reaction. After the reaction was completed, 65 g of 27% ammonia water (0.5007 mol) was added. Heat up to 80°C to dissolve, add 2g of activated carbon to decolorize for 0.5h, press filter while hot, and cool the filtrate to 25°C to grow crystals for 1h. The material was sucked and filtered to dryness, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com