Process for preparing hydroxylamine salt by continuous hydrolysis of oxime

The technology of a hydroxylamine salt and a process is applied in the field of a new process for the preparation of hydroxylamine salt, can solve the problems of residual oxime in hydrolyzate, catalyst deactivation, oxime loss and the like, and achieves the advantages of simple post-treatment process, simple synthesis method and high product selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

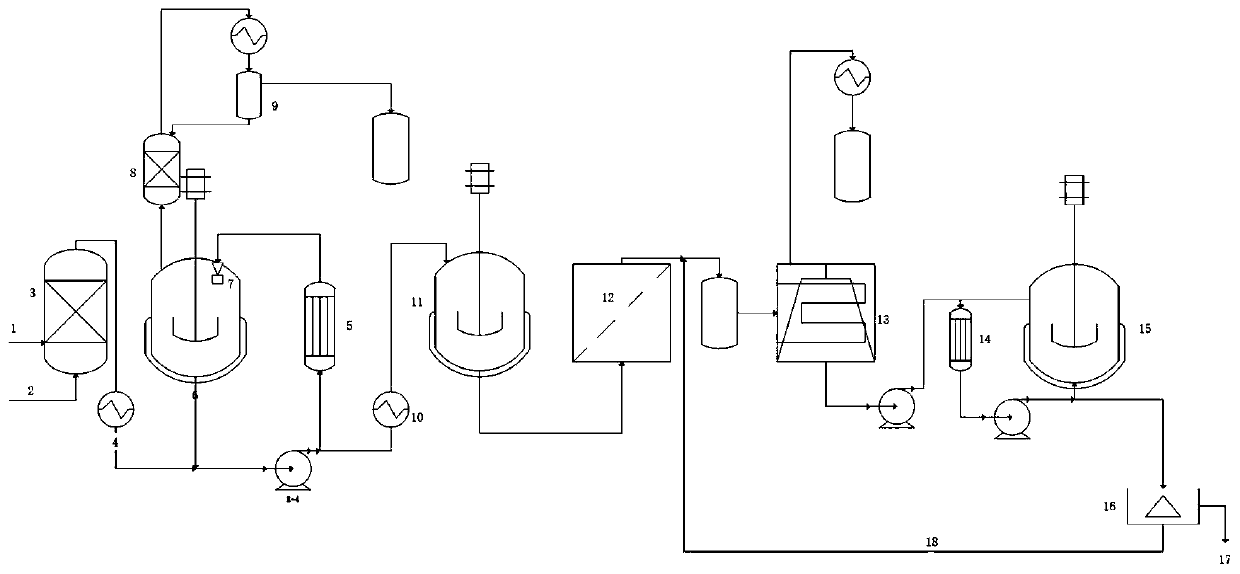

[0036] A process for preparing hydroxylamine salt by continuous hydrolysis of oxime, using oxime and acid as raw materials, continuous production, and realizing the process through the following devices;

[0037] The concrete structure of described device is as follows:

[0038] The oxime source 1 and the acid source 2 are connected to the static mixer 3, the top of the static mixer 3 is connected to the preheater 4, the preheater 4 is connected to the external heat exchanger 5 of the hydrolysis kettle, and the external heat exchanger 5 of the hydrolysis kettle is connected to the top of the hydrolysis kettle 6, The top of the hydrolysis kettle 6 is connected to the condenser 8, the condenser 8 is connected to the liquid separator 9, and the liquid separator 9 is connected to the ketone collecting device;

[0039] The bottom of the hydrolysis kettle 6 is connected to the heat exchanger 10, the heat exchanger 10 is connected to the top of the decolorization kettle 11, the botto...

Embodiment 2

[0047] A new process for preparing hydroxylamine salt by continuous hydrolysis of oxime. Oxime 1 and acid 2 are continuously fed into static mixer 3 at a ratio of 1.1:1, and the acid and oxime are fully mixed to obtain a hydrolyzed stock solution; the hydrolyzed stock solution is preheated by a preheater 4 to 50°C; the preheated hydrolysis stock solution continuously enters the inlet of the external heat exchanger 5 of the hydrolysis kettle, and starts hydrolysis for 3 minutes after being heated to 65°C, and the ketone and hydroxylamine obtained by hydrolysis are separated above the hydrolysis kettle 6, and the hydrolyz The upper connection port is a Venturi-type injector 7; the rising steam of the hydrolysis kettle brings the vaporized ketone into the condenser 8, and the condensate is separated by liquid separator 9, and the water phase after liquid separation is returned to the hydrolysis kettle for separation. The ketone obtained from the solution is used for the oximation ...

Embodiment 3

[0049] Butanone oxime and acid are continuously fed into the static mixer at a ratio of 1.3:1 to configure the hydrolyzate. The outlet of the static mixer is connected to the inlet of the heat exchanger outside the hydrolysis kettle, and the feed rate is maintained at 200kg / h. Heater continuous hydrolysis, adjust circulation pump to 12.5m 3 / h, while the production liquid flow rate is 200kg / h, the temperature at the bottom of the tank is 106°C, and the azeotrope of ketone and water is produced at the top of the tower. The extracted hydrolyzate is decolorized with activated carbon for about 30 minutes, and the decolorization temperature is 60°C. The decolorization liquid is dehydrated by a concentrated evaporation device, the dehydration temperature is less than 80°C, and the pressure is ≥-0.095MPa. After the concentrated solution is cooled by a continuous cooling crystallizer, the product is centrifugally dried, and the product purity reaches 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com