Instrument cleaning device for constructional engineering

A technology for construction engineering and cleaning devices, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc. It can solve the problems of cumbersome process, time-consuming and labor-intensive cleaning of equipment, and low cleaning efficiency, so as to achieve thorough cleaning , saving engineering cost, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

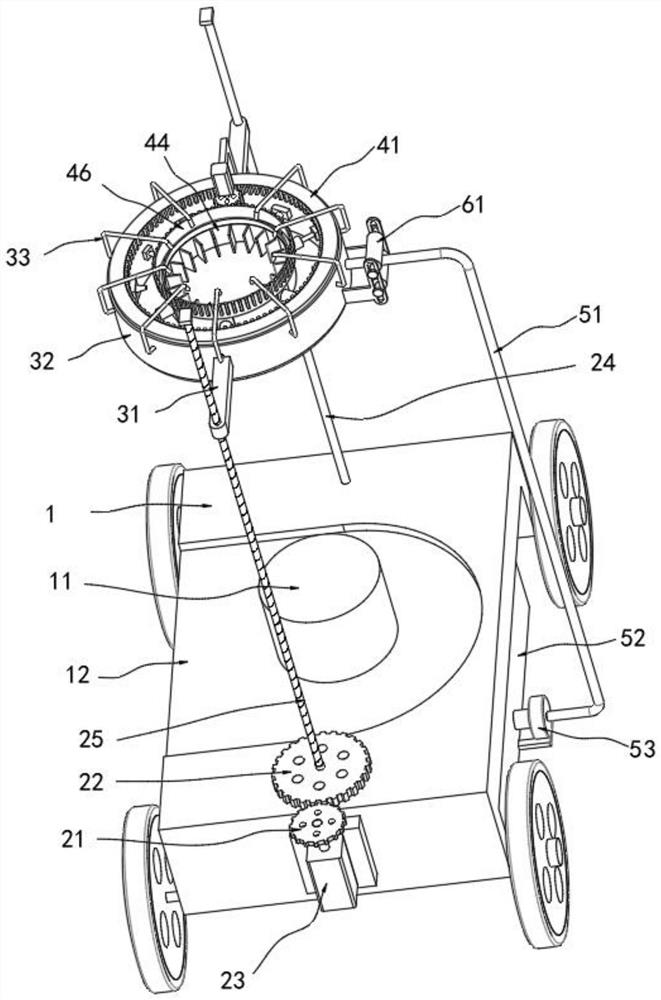

[0037] An instrument cleaning device for construction engineering, characterized in that it includes a base 1, a support assembly 2, a spray assembly 3, a brush plate assembly 4 and a cleaning assembly 5, and the base 1 is provided with a fixing seat 11 for fixing the instruments to be cleaned , the spray assembly 3 is connected to the base 1 through the support assembly 2, the cleaning assembly 5 is connected to the spray assembly 3 and the base 1 respectively, and is used for the spray assembly 3 to provide cleaning liquid, and the adjustment of the support assembly 2 can adjust the longitudinal height of the spray assembly 3, and the brush plate The component 4 is connected with the spraying component 3 and can scrub the surface of the instrument.

[0038] The support assembly 2 includes a first gear 21, a second gear 22, a first drive motor 23, a guide rod 24 and a screw mandrel 25, the first drive motor 23 is connected with the base 1 and its output end is connected with t...

Embodiment 2

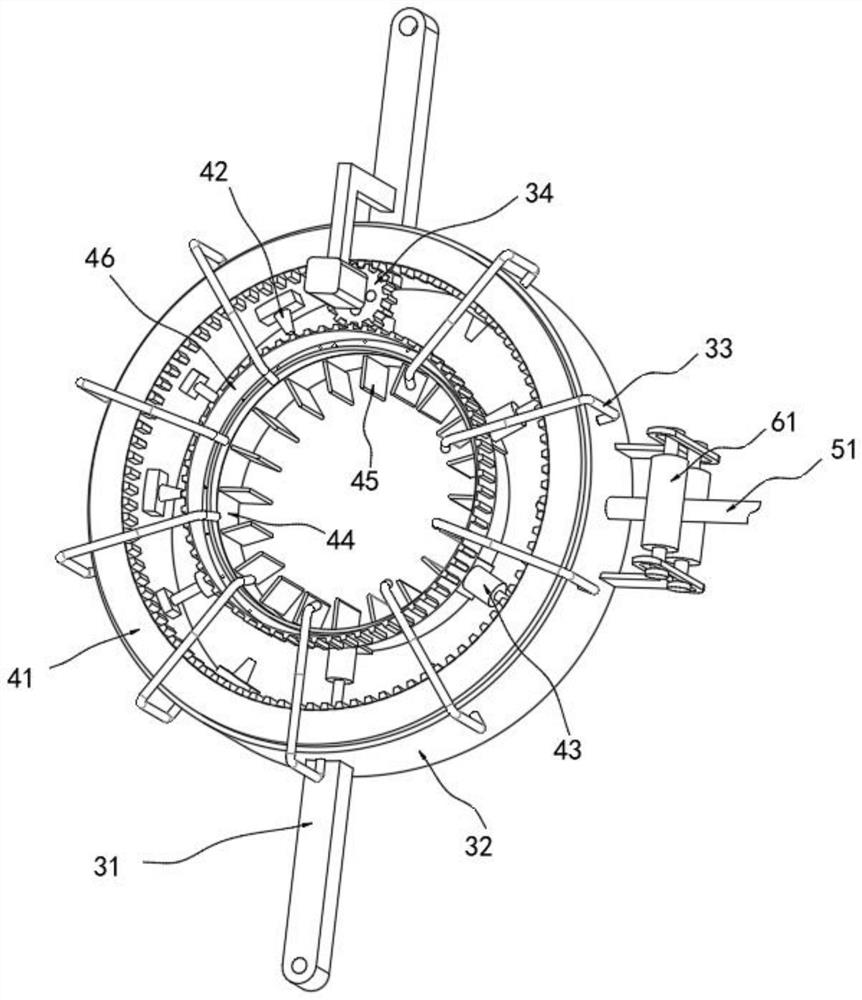

[0046] Compared with Embodiment 1, the difference is that in this embodiment, the protection groove 46 is higher than the top of the third gear 34 on the side close to the water delivery ring 32, and the protection groove 46 is higher than the structure outer wall of the third gear 34 and the third gear. 34 mesh connection.

[0047] An instrument cleaning device for construction engineering, characterized in that it includes a base 1, a support assembly 2, a spray assembly 3, a brush plate assembly 4 and a cleaning assembly 5, and the base 1 is provided with a fixing seat 11 for fixing the instruments to be cleaned , the spray assembly 3 is connected to the base 1 through the support assembly 2, the cleaning assembly 5 is connected to the spray assembly 3 and the base 1 respectively, and is used for the spray assembly 3 to provide cleaning liquid, and the adjustment of the support assembly 2 can adjust the longitudinal height of the spray assembly 3, and the brush plate The co...

Embodiment 3

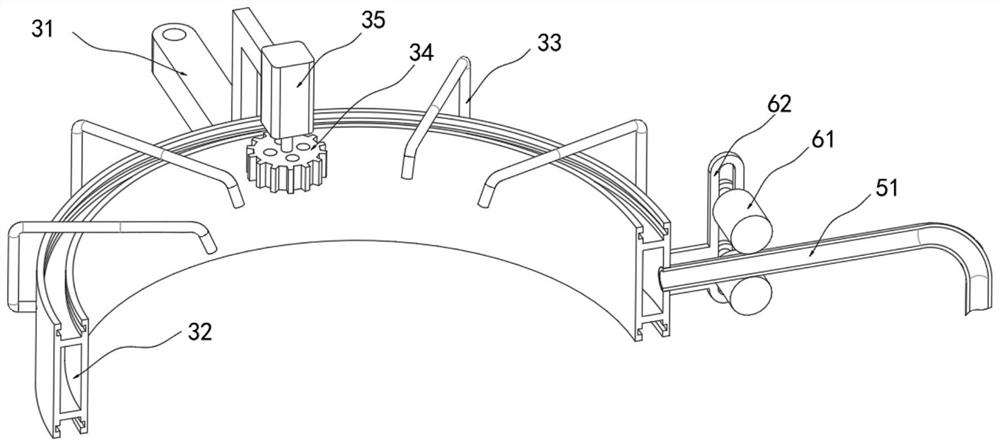

[0057] Compared with Embodiment 1 and Embodiment 2, this embodiment also includes an extruding device 6 .

[0058] An instrument cleaning device for construction engineering, characterized in that it includes a base 1, a support assembly 2, a spray assembly 3, a brush plate assembly 4 and a cleaning assembly 5, and the base 1 is provided with a fixing seat 11 for fixing the instruments to be cleaned , the spray assembly 3 is connected to the base 1 through the support assembly 2, the cleaning assembly 5 is connected to the spray assembly 3 and the base 1 respectively, and is used for the spray assembly 3 to provide cleaning liquid, and the adjustment of the support assembly 2 can adjust the longitudinal height of the spray assembly 3, and the brush plate The component 4 is connected with the spraying component 3 and can scrub the surface of the instrument.

[0059] The support assembly 2 includes a first gear 21, a second gear 22, a first drive motor 23, a guide rod 24 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com