Autorotation type frying pan

An automatic rotation and frying pan technology, which is applied in frying pans, household utensils, applications, etc., can solve the problems of reduced efficiency, high labor intensity for processors, and inconvenient operation, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

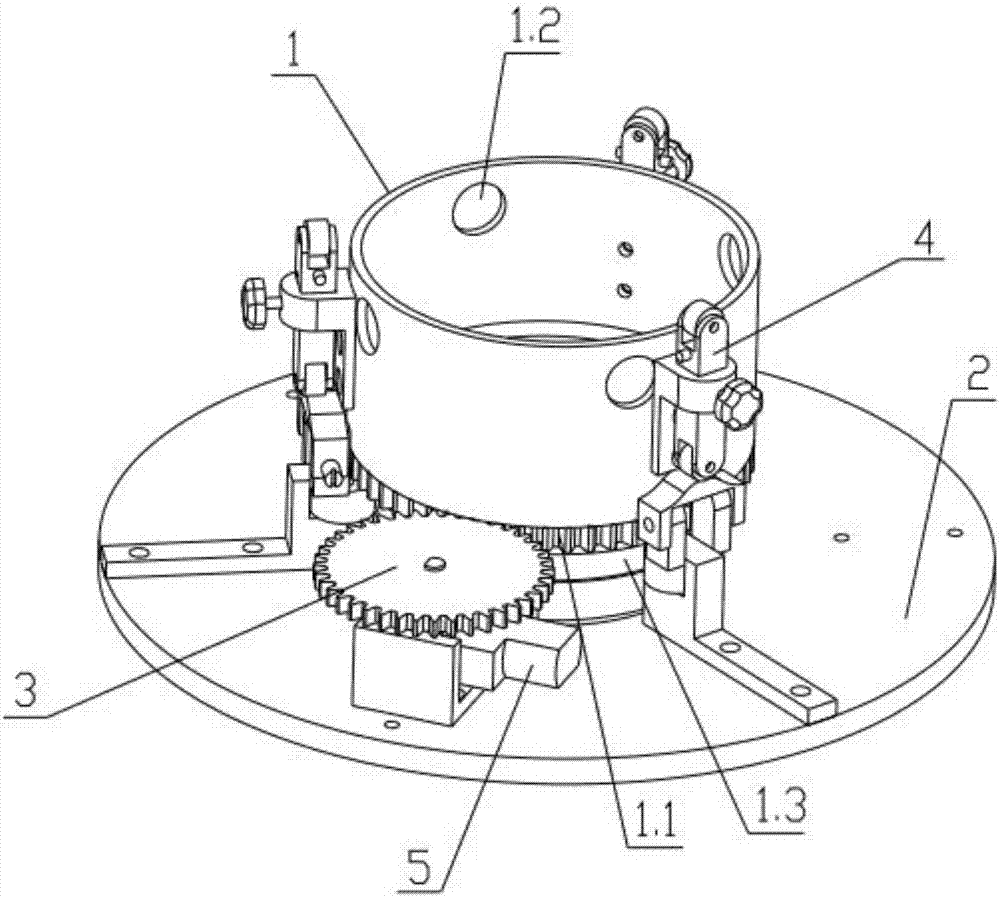

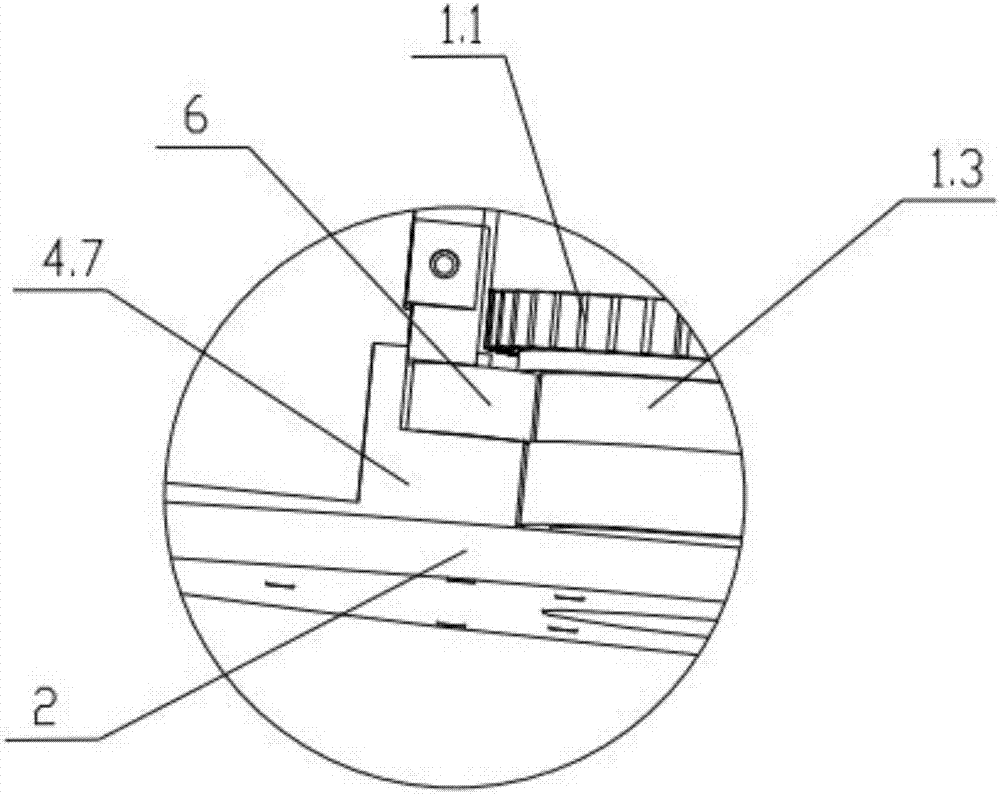

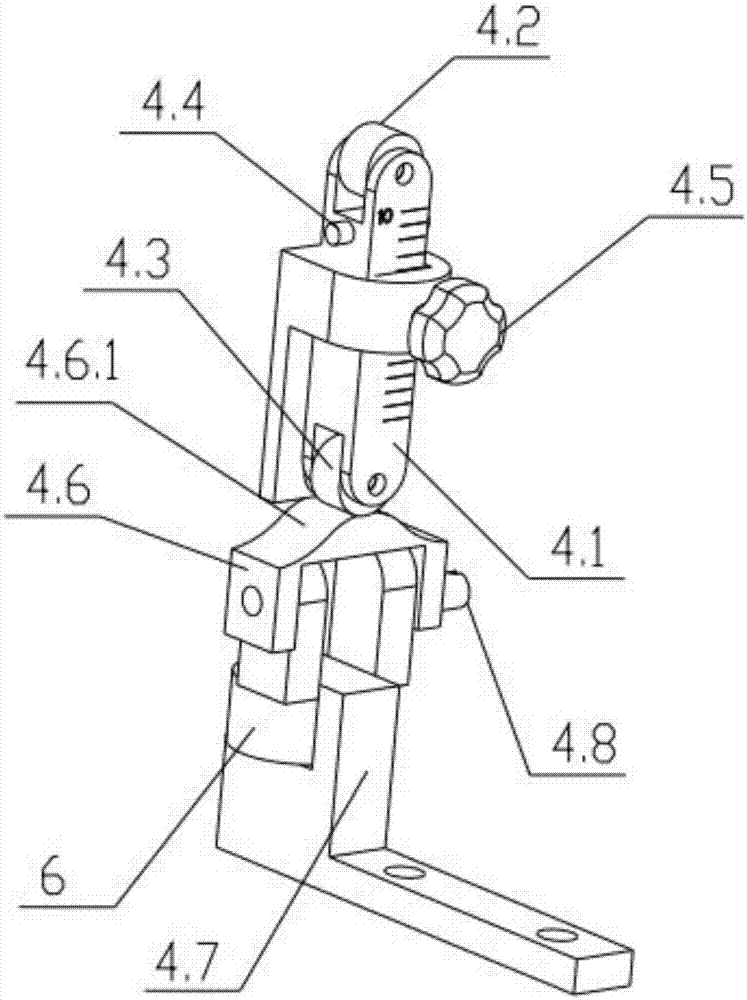

[0021] Such as Figure 1 to Figure 4 As shown, an automatic rotating frying pan includes a pot body, a drive assembly, a base 2 and a pot base 1 installed on the base, the pot body is arranged at the upper end of the pot base, and the drive assembly drives the The pot base 1 rotates along its circumference; the base 2 is provided with a plurality of lifting mechanisms 4, the upper ends of the lifting mechanisms 4 are against the lower side of the edge of the pot body, and the lifting mechanisms 4 move up and down to drive the The edge of the pot body mentioned above is raised or lowered. The lifting mechanism 4 includes an arc-shaped boss installed on the base and a lifting rod 4.1 that can be moved up and down on the outer wall of the pot seat; the upper end of the arc-shaped boss is provided with an upwardly protruding arc surface 4.6. 1. The lower end of the lifting rod 4.1 driven by the pot base 1 can move along the arc surface 4.6.1. The pot base 1 drives the pot body t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com