Sheep feed fermentation integrated equipment

A sheep feed and equipment technology, applied in the field of integrated sheep feed fermentation equipment, can solve problems such as unfavorable fermentation treatment, ineffective penetration of mixed liquid, poor material humidification effect, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

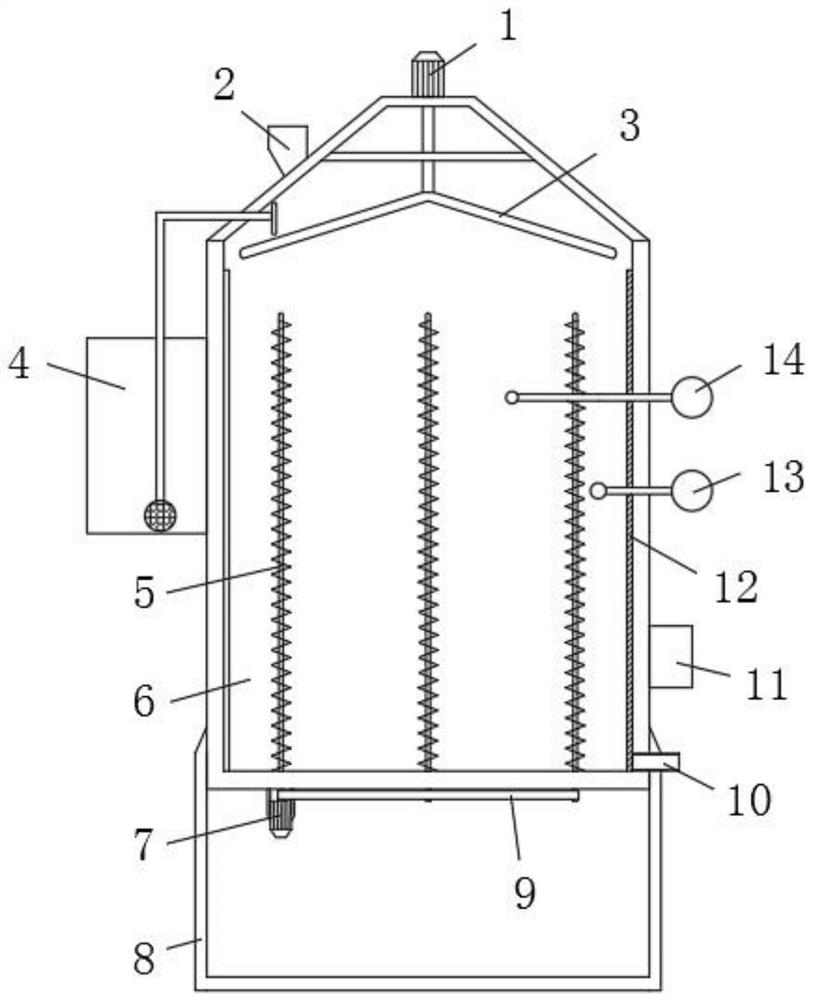

[0037] Such as figure 1 As shown, an integrated sheep feed fermentation equipment includes a fermentation bin 6:

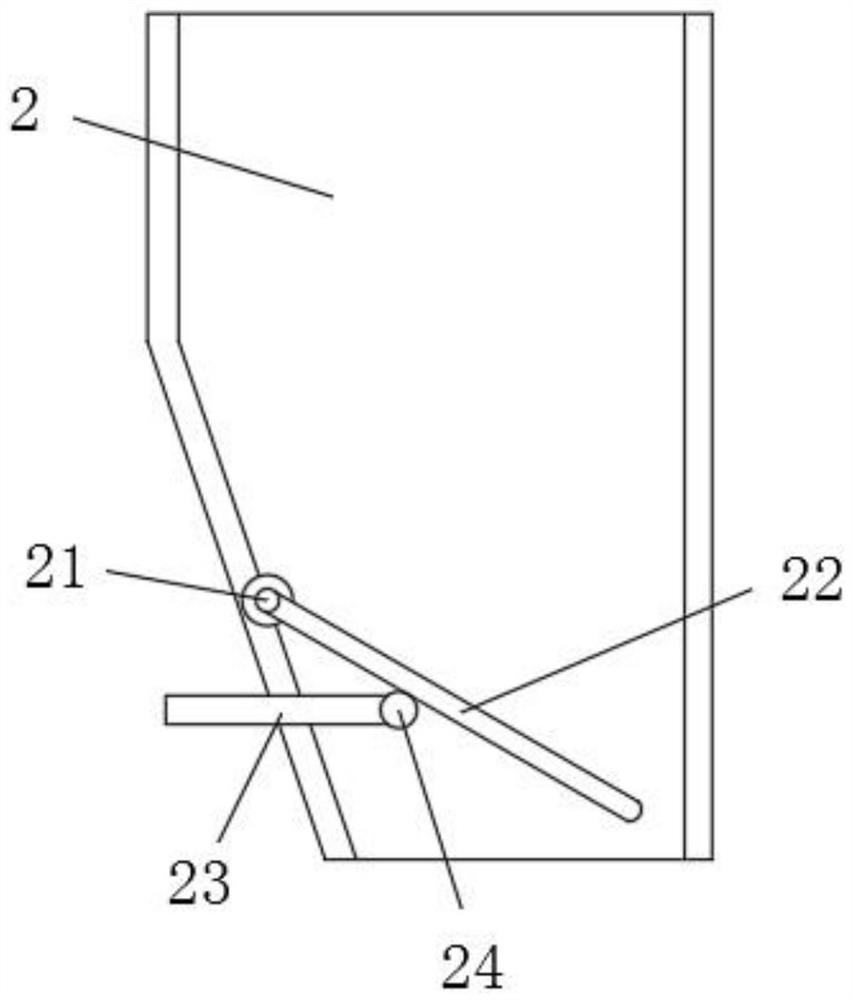

[0038] The top of the fermentation bin 6 is provided with a feeding bin 2;

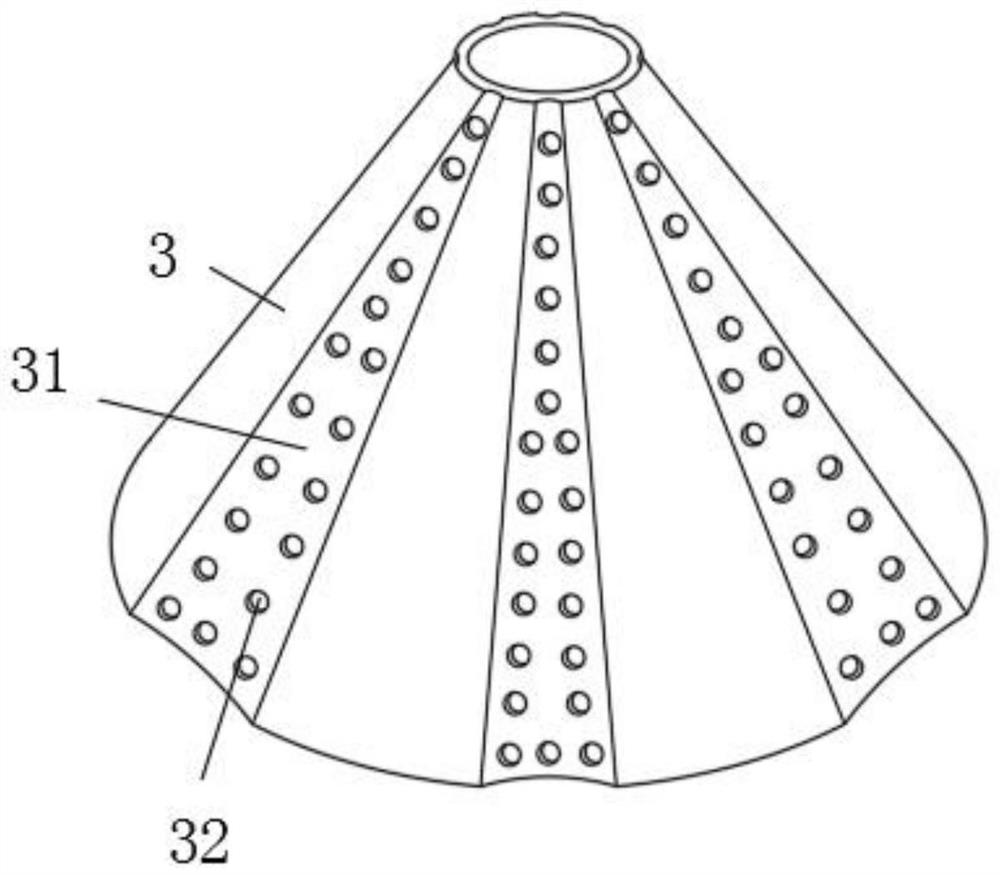

[0039] The top of the fermentation bin 6 is provided with a first motor 1, and the output end of the first motor 1 is connected with a shunt cover 3 extending into the fermentation bin 6;

[0040] The outer wall of the fermentation bin 6 is provided with a humidification assembly 4, and the atomization port of the humidification assembly 4 extends into the fermentation bin 6 and is located between the outlet of the feed bin 2 and the shunt cover 3;

[0041] The bottom of the fermentation bin 6 is provided with a discharge pipe 10 , and the bottom of the fe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap