Quick dismounting structure for guide disc of false twist texturing machine

A false twist texturing machine, fast technology, applied in textiles and papermaking, etc., can solve problems such as inability to quickly install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

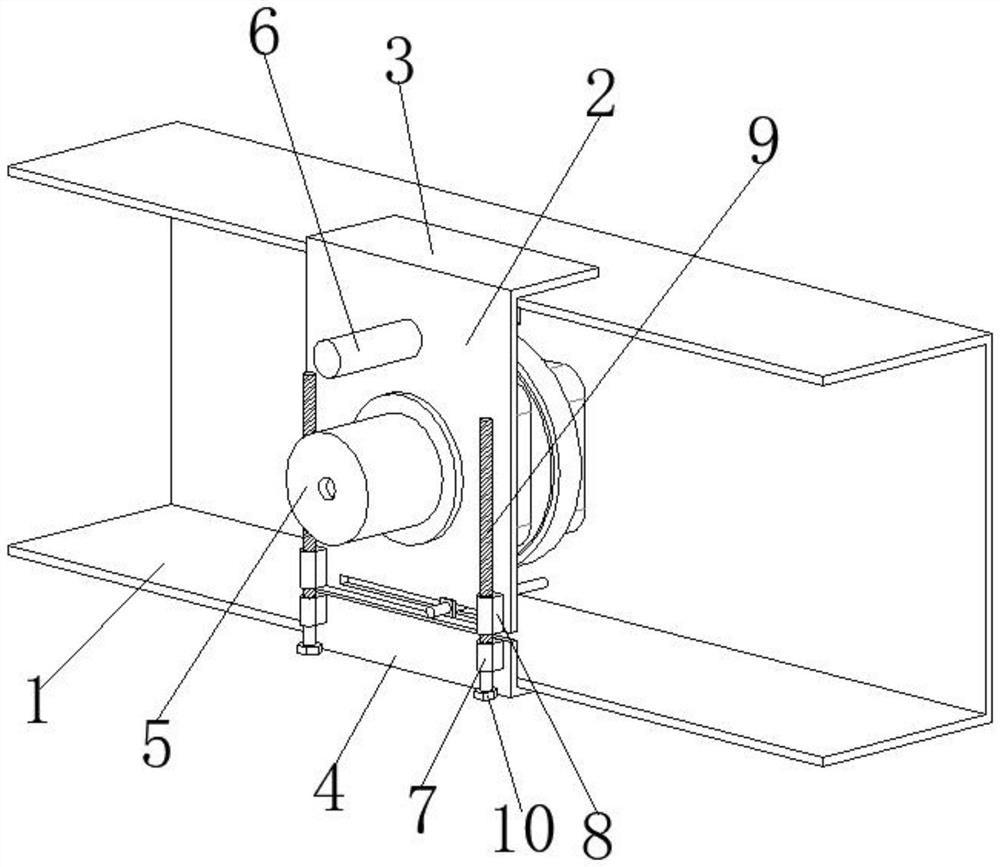

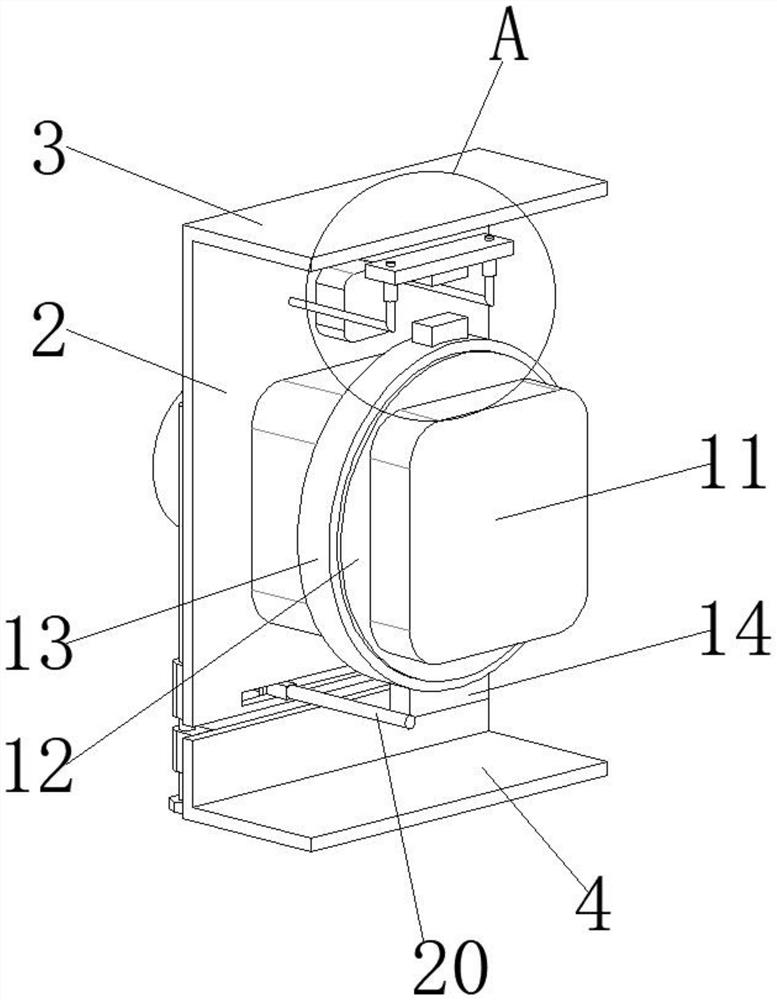

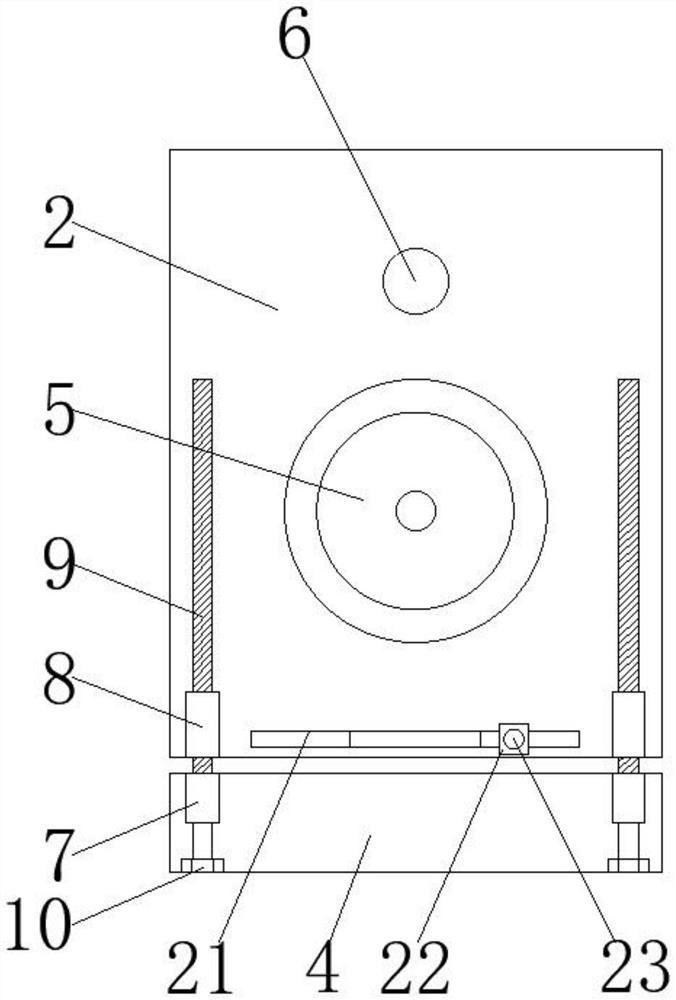

[0029] The embodiment of the present invention provides a quick disassembly structure for the guide plate of the false twist texturing machine, such as Figure 1-5 As shown, the beam 1 is included, the cross-section of the beam 1 is set in the shape of a 匚, the opening side of the beam 1 is provided with a panel 2, the front of the panel 2 is equipped with a split roller 6 and a godet 5, and the back of the panel 2 is fixedly connected. The driving motor 11 for driving the godet 5, the top of the panel 2 is fixedly connected with the first splint 3, the bottom of the panel 2 is provided with the second splint 4, and the second splint 4 is provided between the panel 2 and the second splint 4 for adjusting the second splint. 4-position adjustment mechanism, the adjustment mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com