Grinding tooth cut-off length calculation method for pulping equipment equipped with straight tooth element

A calculation method and component technology, applied in pulp beating/refining method, textiles and papermaking, papermaking, etc., can solve the problems of wrong judgment of strength, lack of consideration of the actual physical meaning of cutting length, etc., to promote optimal control and realization of parameters The effect of computing and promoting energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, which are explained by the present invention and not limiting.

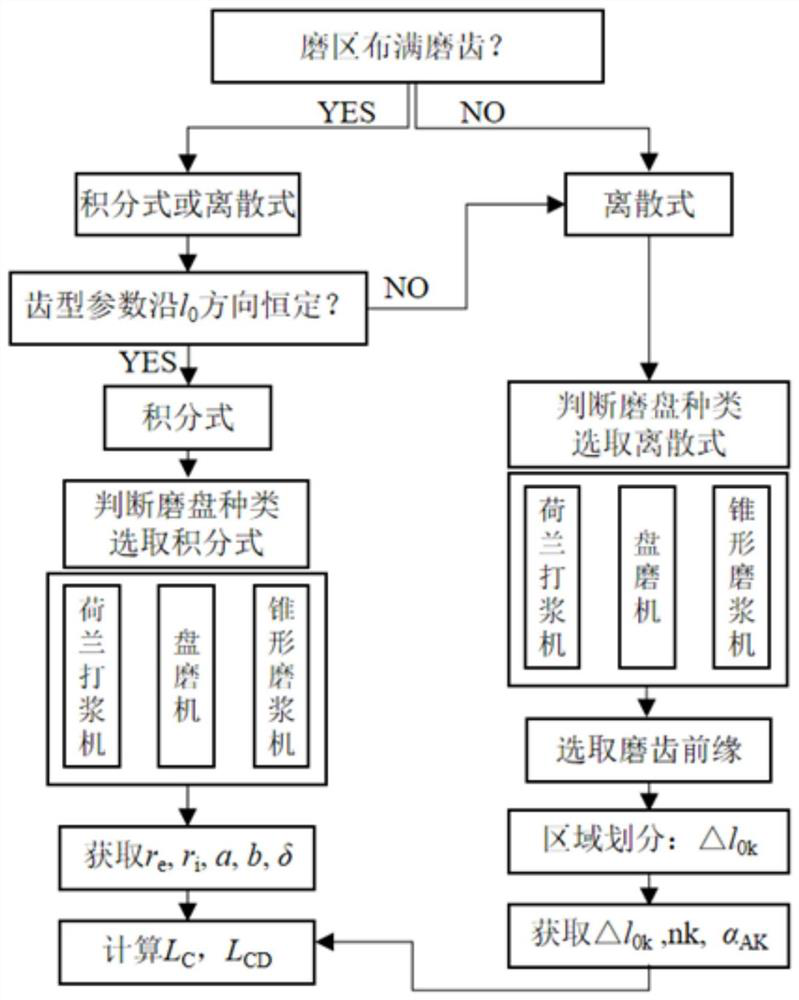

[0035] The method of the present invention is like figure 1 As shown, including:

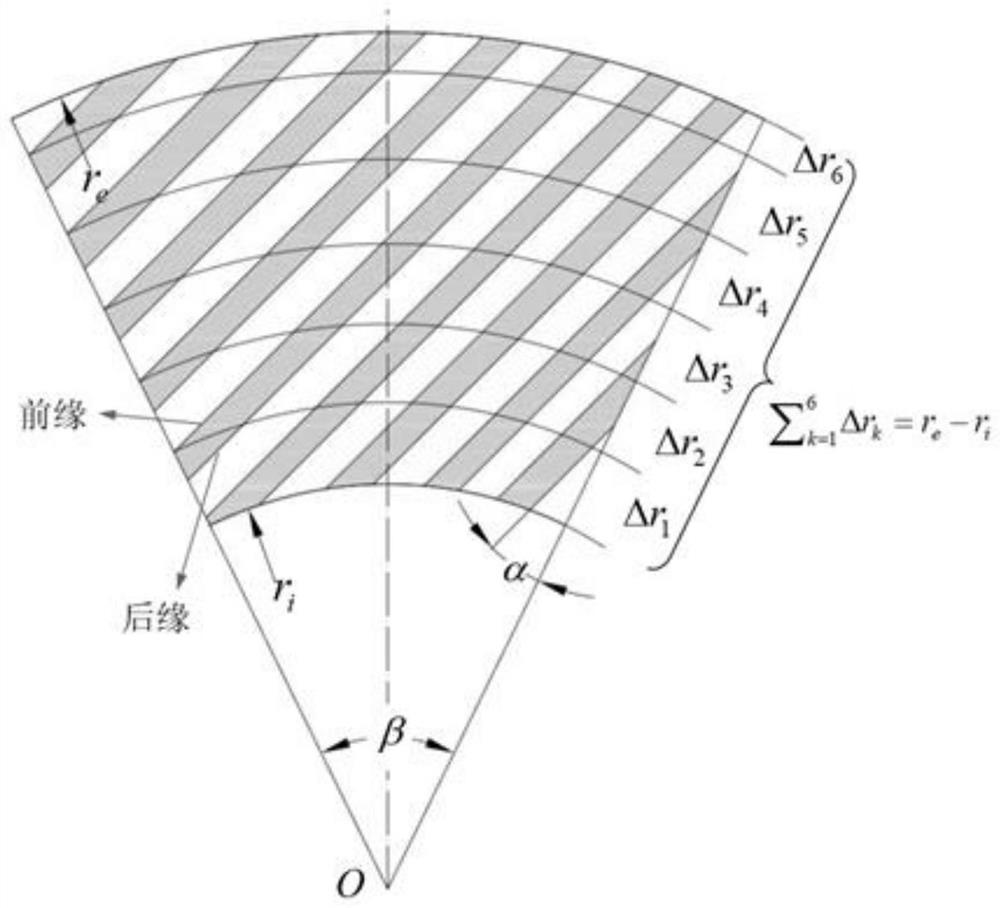

[0036] S1: According to the change in the reference length direction, select the integration calculation or discrete calculation of the ratio of the integrated or discrete calculation; if the straight toothed parameters are constant in the direction of the reference length, and the mill Full-grubble, strategic selection of integral calculation or discrete calculation; if the straight toothed parameter is constant in the direction of the reference length, the partial wear area is not arranged, and the grinding is calculated. Select discrete calculation; if the straight toothed element is changed in the direction of the reference length, the discrete calculation is selected by the grinding cutting length;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com