Oil and gas drilling shaft state monitoring method and device

A technology for oil and gas drilling and wellbore, which is applied in wellbore/well components, measurement, earthwork drilling, etc., and can solve the problems of untimely monitoring, low monitoring accuracy, difficult drilling and safe construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

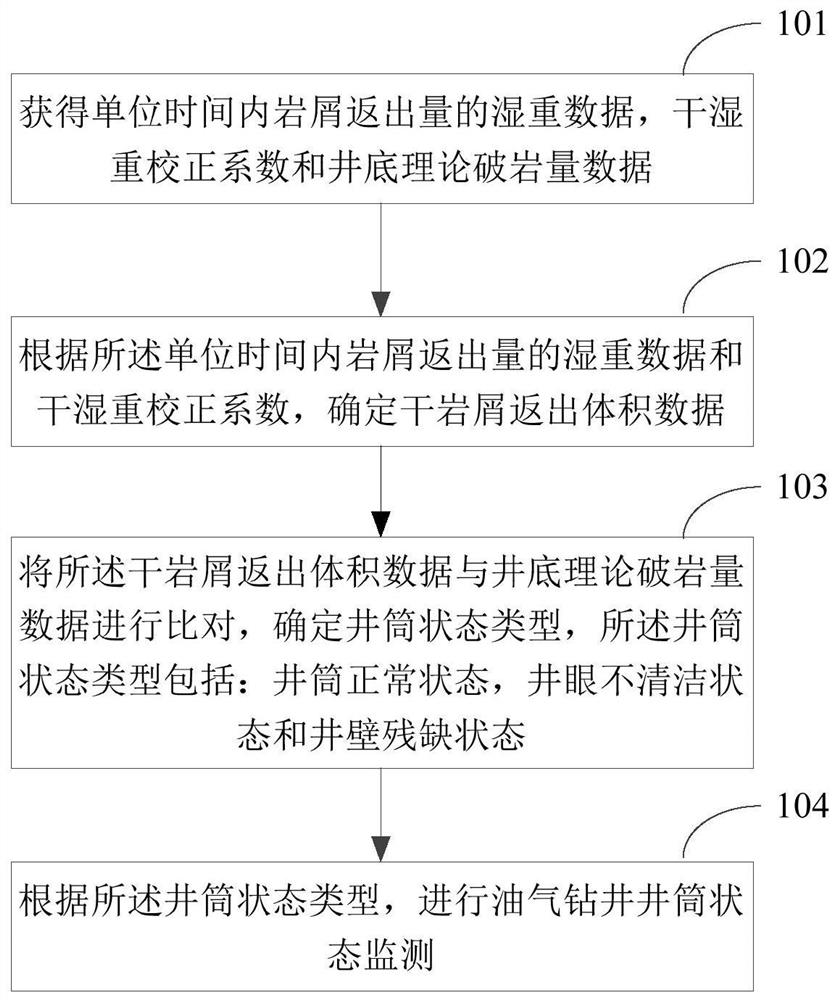

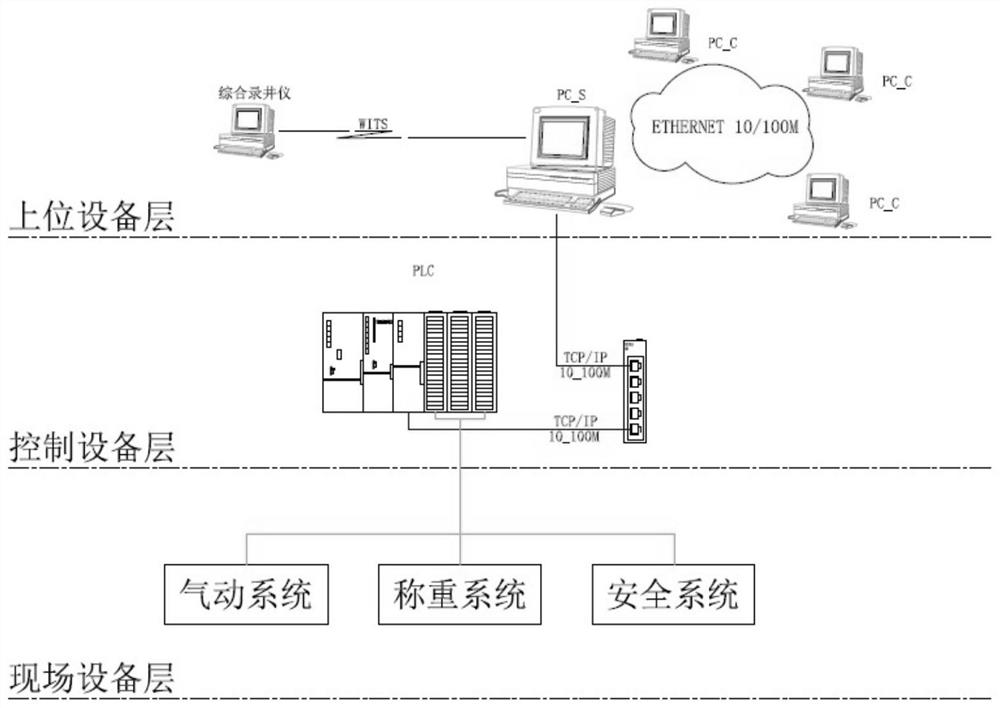

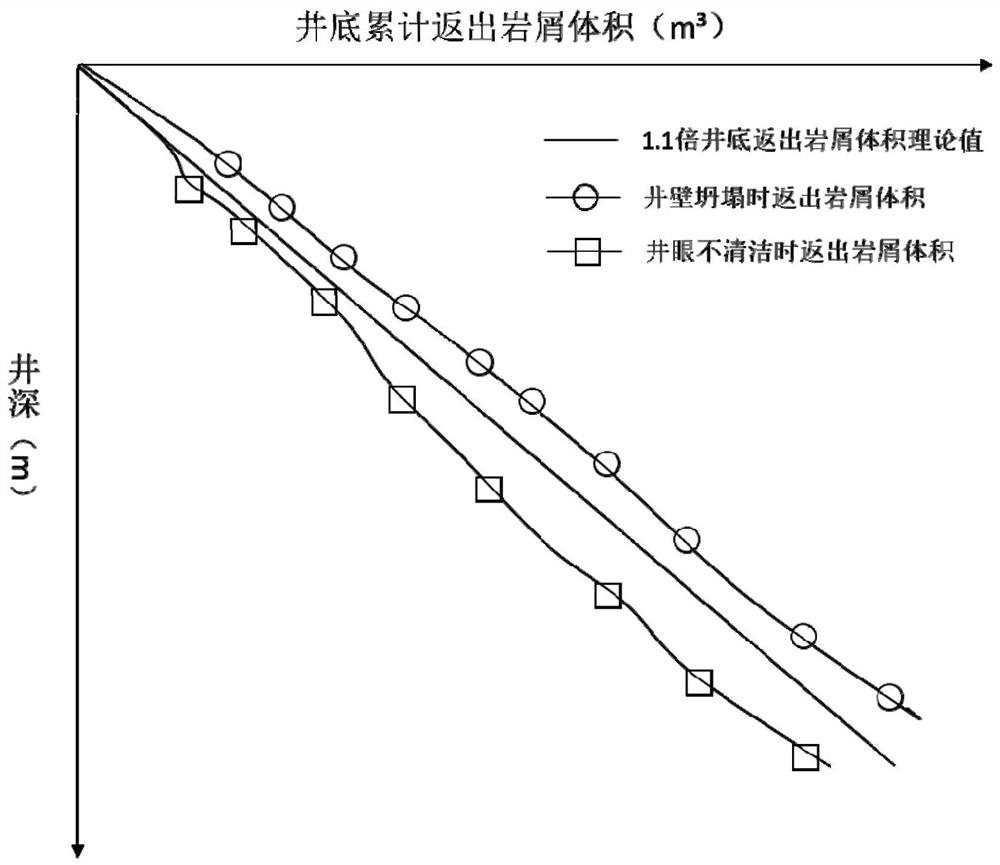

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0023] As mentioned above, scholars in the prior art have proposed a variety of methods to evaluate the state of the wellbore: (1) By monitoring the image of cuttings returned from the ground vibrating screen, it is judged whether the bottom of the well has collapsed or accumulation of cuttings. The main method of the method is to monitor the stability of the borehole wall. To a certain extent, the amount of cuttings returned can also be used to monitor the deposition of cuttings at the bottom of the well; (2) By arranging pressure sensors along the pipe string, real-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com