Panel pillar advanced pressure relief subsequent filling mining method

A mining method and ore pillar technology, which can be used in filling, ground mining, mining equipment, etc., can solve problems such as low work efficiency and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

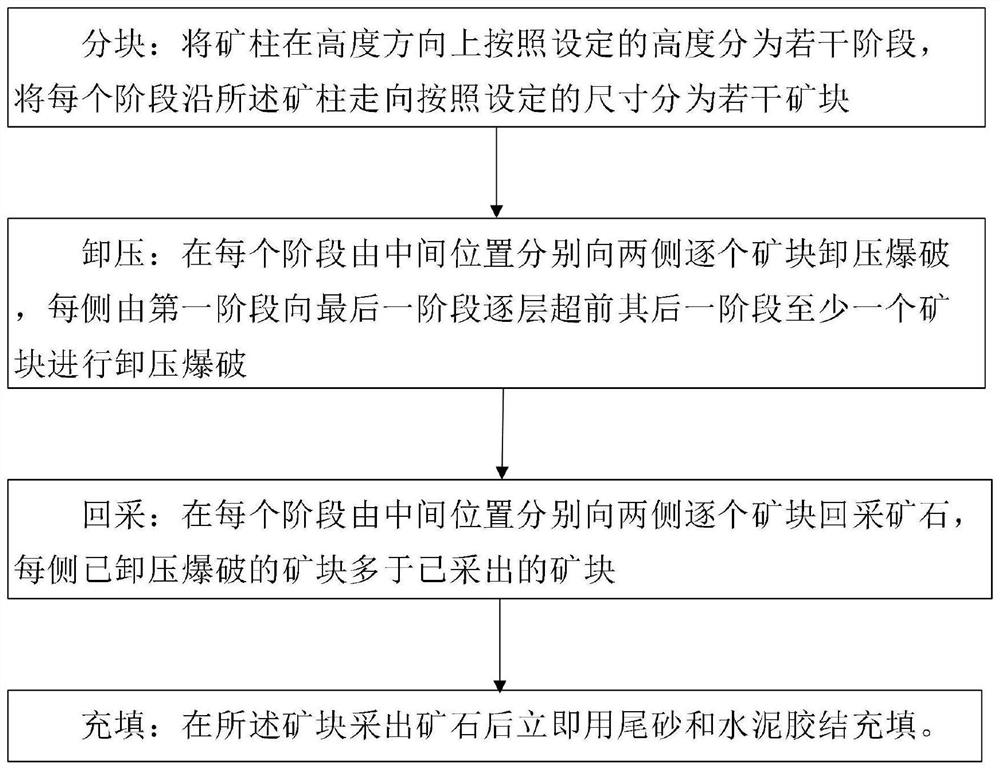

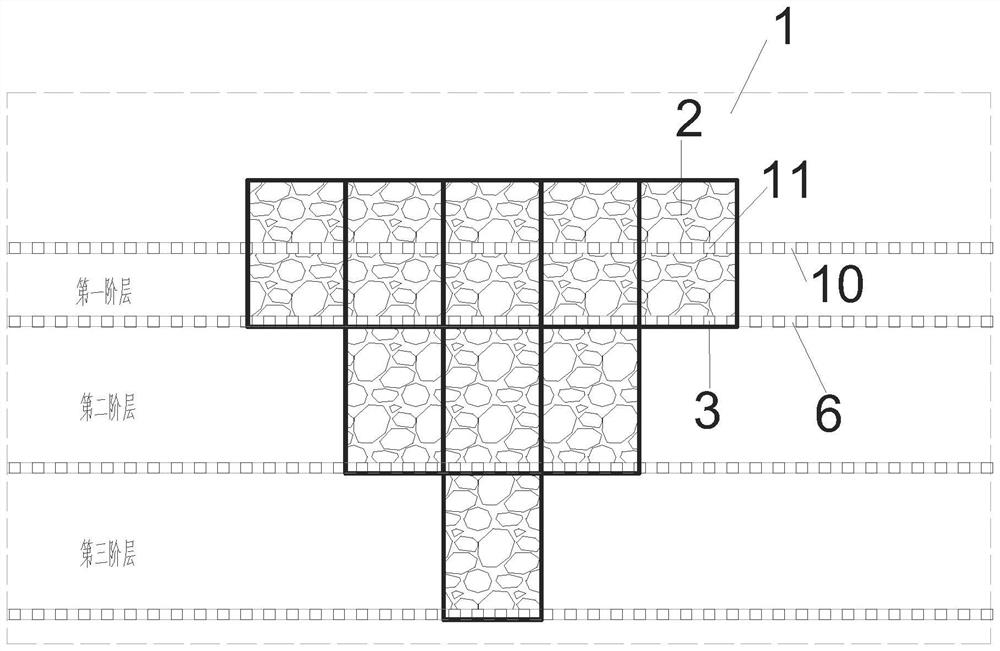

[0031] figure 1 It is a flow chart of the mining method for panel pillars in advance of depressurization and subsequent filling according to Embodiment 1 of the present invention, figure 2 It is a structural schematic diagram of the pressure relief in advance from the top of the ore pillar according to Embodiment 1 of the present invention.

[0032] like figure 1 and figure 2 It can be seen that the mining method for panel pillars proposed in this embodiment is to relieve pressure in advance and then fill, which can be used for safe recovery of panel pillars in extra-large deep wells. Panel pillars refer to the ore pillars left to support the panel roof and ensure the safety and stability of the stope structure during the large-scale mining of thick and large ore bodies, generally in the form of cuboids. In open-pit mining, the stope is usually divided into mine rooms and ore pillars, and the ore pillars are recovered after mining in the mine rooms. During the recovery p...

Embodiment 2

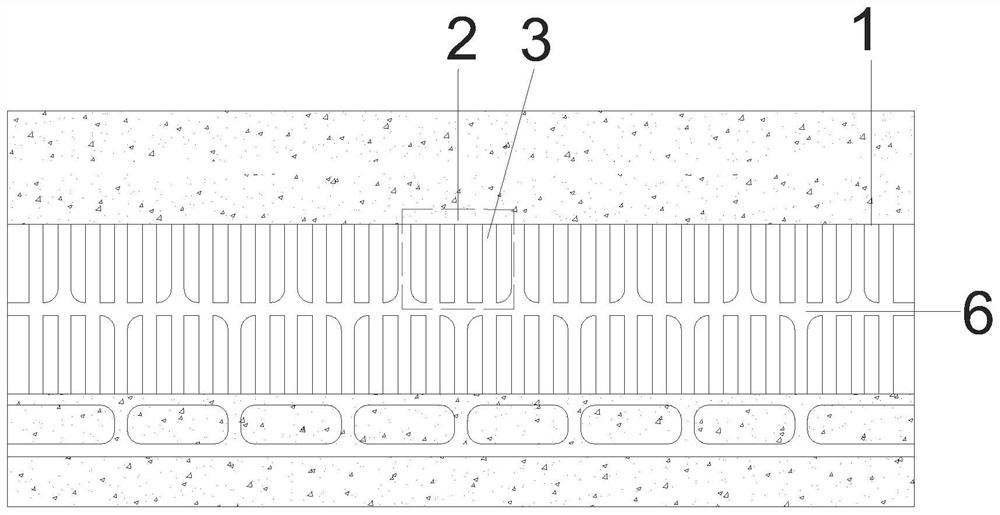

[0062] Figure 8 It is a structural schematic diagram of an advanced pressure relief from the bottom of the pillar according to Embodiment 2 of the present invention.

[0063] like Figure 8 As shown, the panel mining method provided by this embodiment is based on the first embodiment, and starts from the bottom of the pillar to relieve the pressure and then fill. The first stage can be the bottom of the pillar. stage, the last stage is the uppermost stage of the ore pillar. From the bottom to the top, it is divided into the first stage, the second stage, the third stage, etc., and the construction starts from the first stage layer by layer. The ore blocks blasted on each side of the first stage are at least one ahead of the ore blocks blasted on each side of the second stage, and the ore blocks blasted on each side of the second stage are higher than the ore blocks blasted on each side of the third stage At least one ahead, and so on, the ore blocks that have been depressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com