Intelligent gas adjusting valve

A technology of gas regulation and intelligent valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

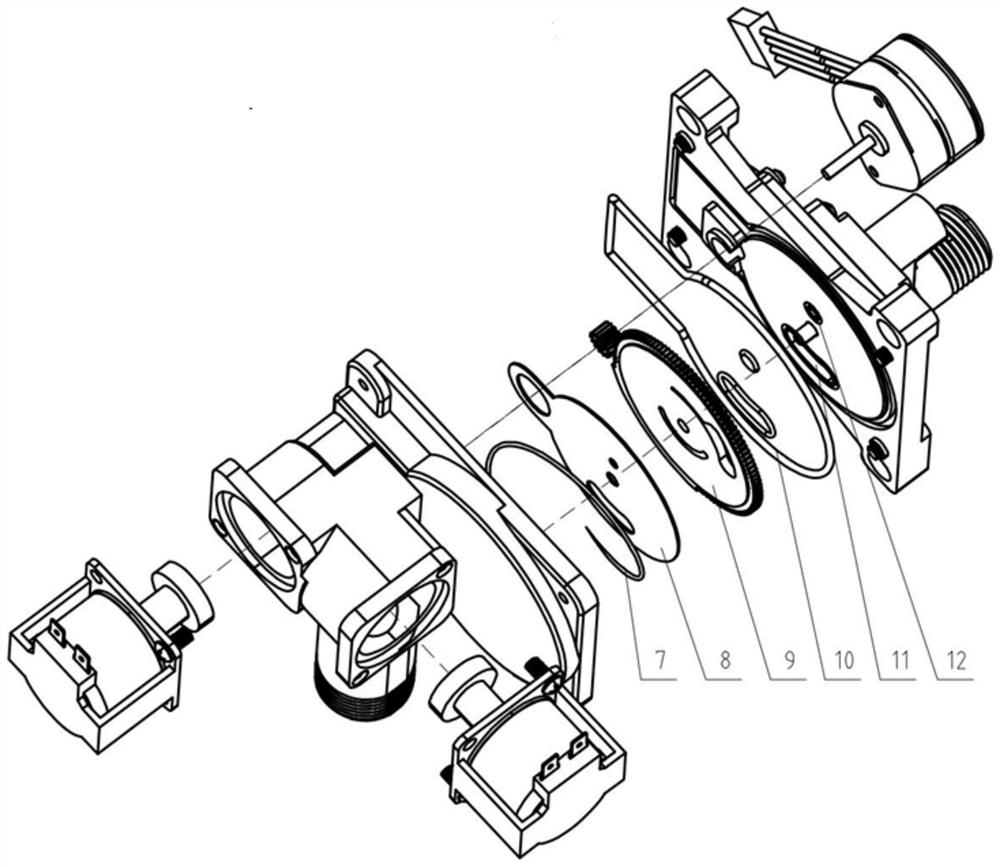

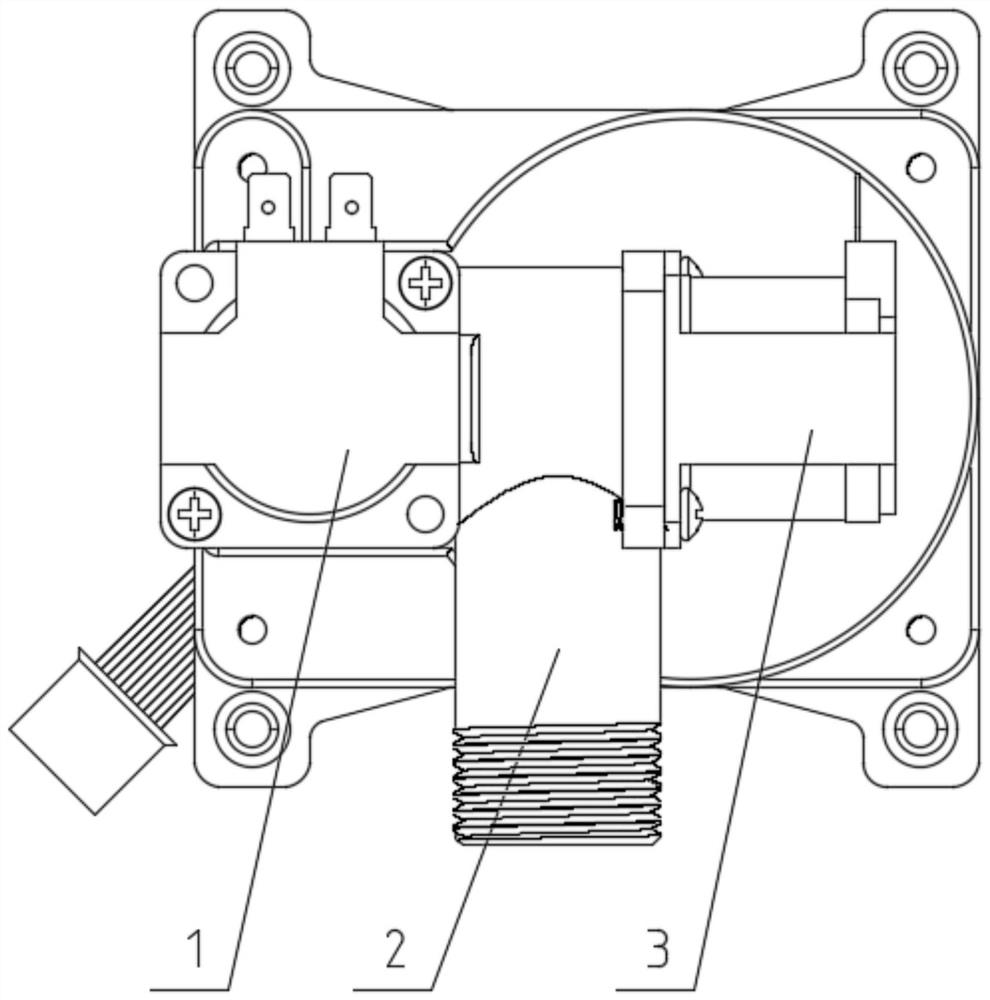

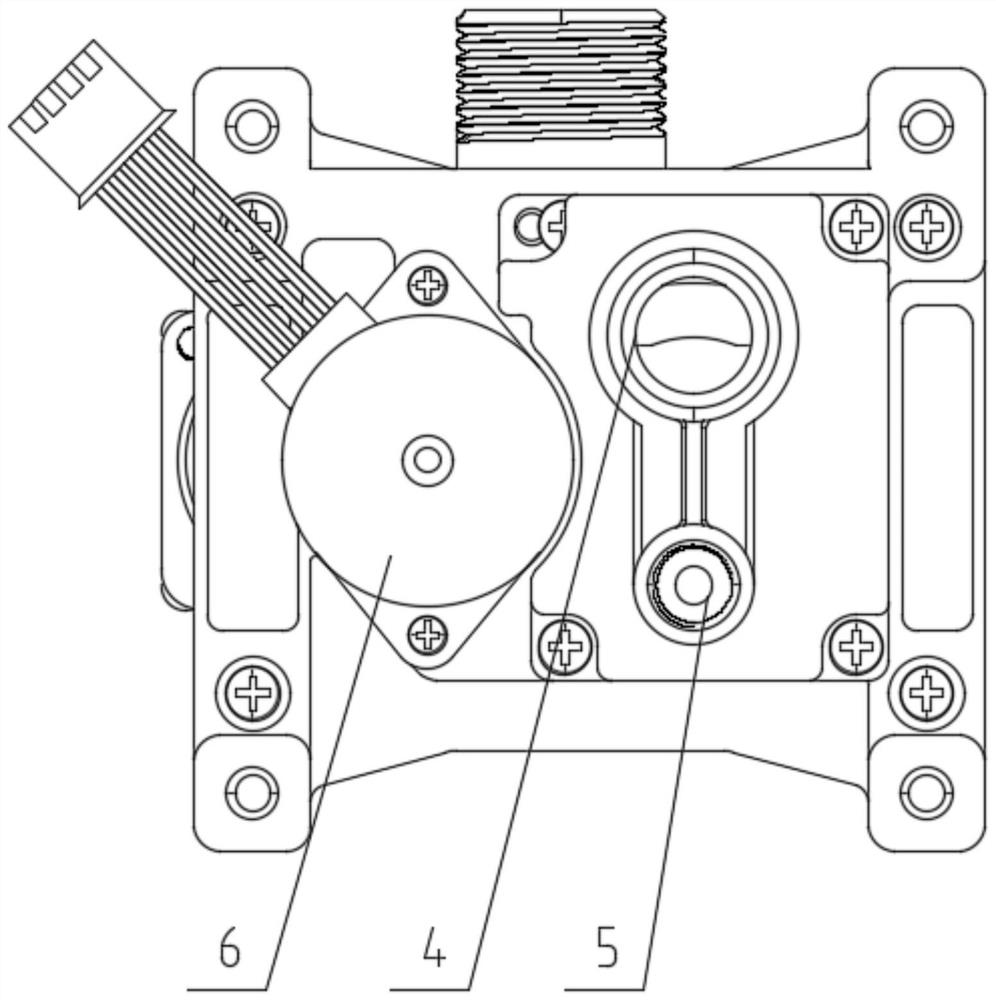

[0034] Such as Figure 1 to Figure 3 As shown, the present invention provides a smart valve for gas regulation, including a valve body provided with a main air inlet 2, a valve cover provided with a small fire nozzle 5 and a large fire nozzle 4, and a small fire nozzle is provided on the inner side of the valve cover corresponding to the small fire nozzle. Air outlet 12, corresponding to the large fire nozzle is provided with a large fire air outlet 11, through the main air inlet to the small fire air outlet and the large fire air outlet gas delivery, also includes the opening and closing of the small fire air outlet, the large fire air outlet and the large fire air outlet Open the size of the air outlet adjustment assembly, the air outlet adjustment assembly includes an adjustment gear 9 and an adjustment motor 6 that drives the adjustment gear to rotate. Adjustment hole.

[0035] Since the small fire adjustment hole and the large fire adjustment hole are all set on the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com