Aluminum ingot smelting processing equipment

A technology for processing equipment and aluminum ingots, which is applied in the field of aluminum ingot smelting and processing equipment, can solve the problems of undisclosed aluminum slag, too dangerous, and labor time consumption, so as to reduce the loss of temperature, facilitate the working speed, and avoid the liquid aluminum bumping out. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

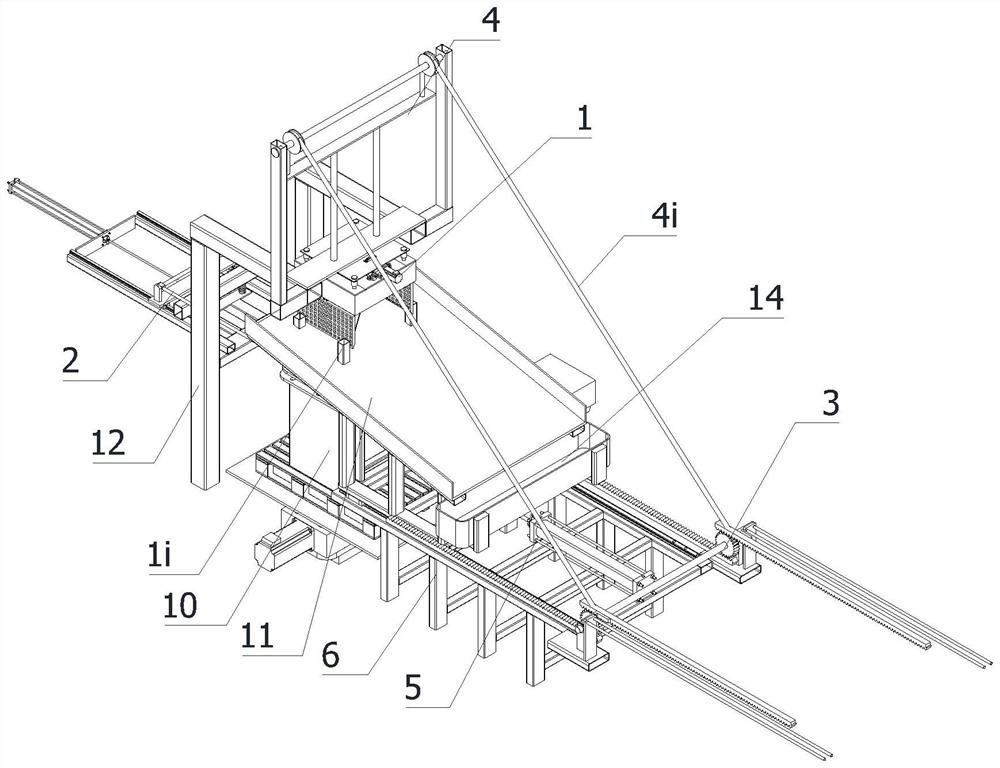

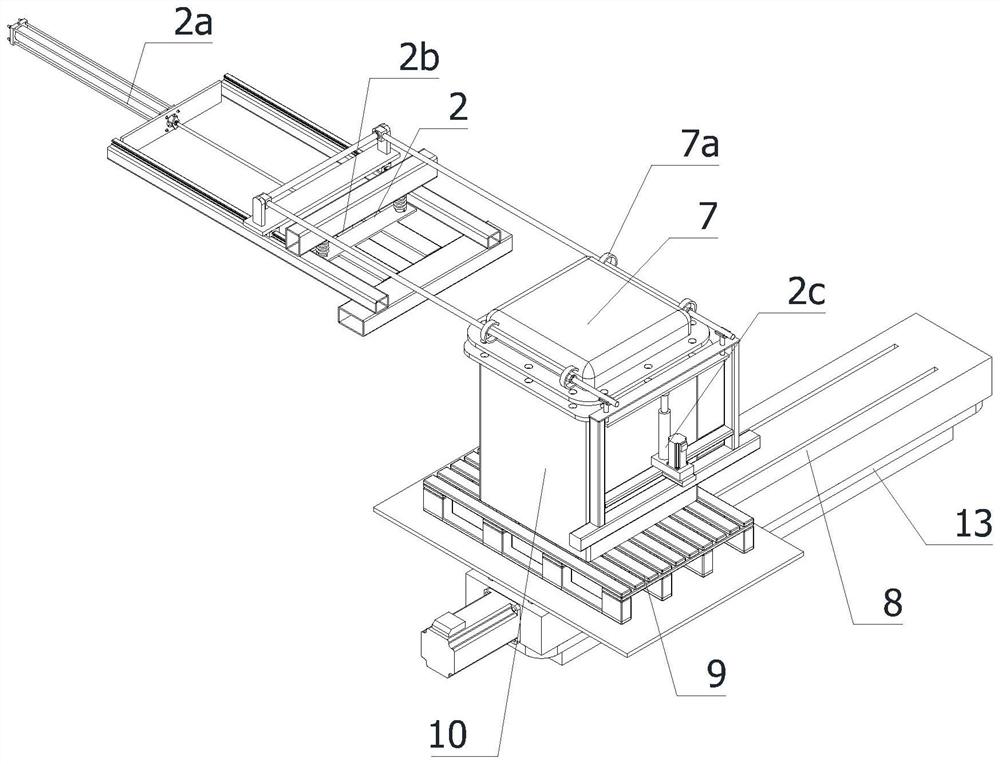

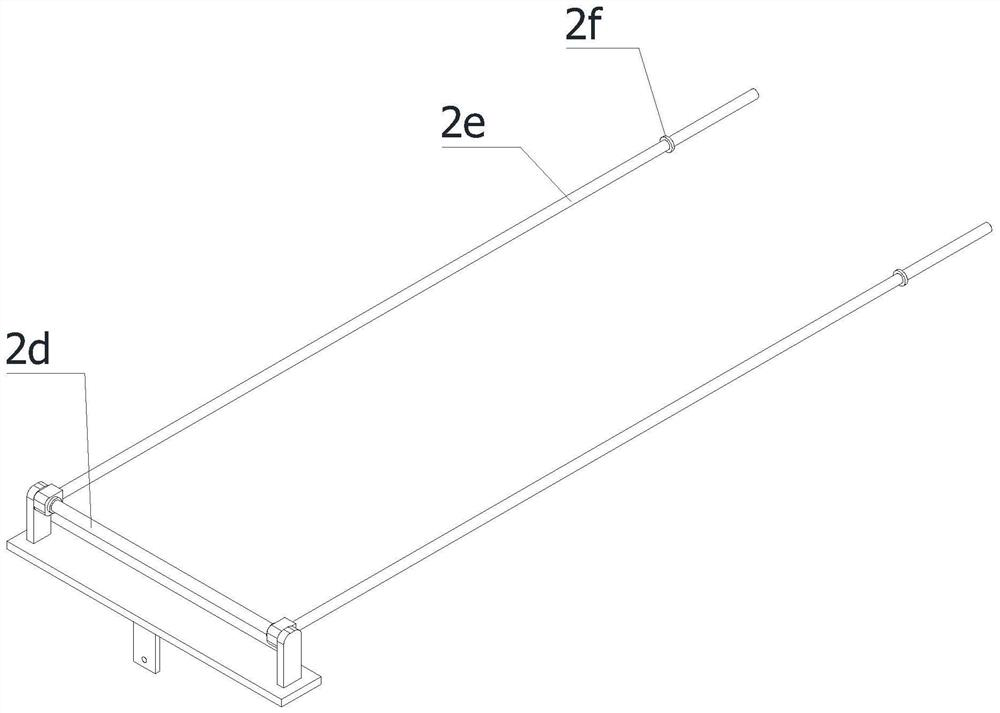

[0040] refer to Figure 1 to Figure 12 The shown aluminum ingot smelting and processing equipment includes a slag collecting mechanism 1, a lower cover mechanism 2, a reverse transmission mechanism 3, a pulling mechanism 4, a second linear pushing mechanism 5, an elevated platform 6, a sealing cover 7, a first The linear movement mechanism 8, the tray 9, the melting cylinder 10 and the liquid guiding frame 11, the first linear movement mechanism 8 is fixedly installed on the ground, the tray 9 is placed on the sliding seat of the first linear movement mechanism 8, the melting cylinder 10 Placed on the tray 9, the sealing cover 7 is set on the top of the melting cylinder 10, the raised platform 6 is located on one side of the first linear movement mechanism 8, and the lower cover mechanism 2 is located on the other side of the first linear movement mechanism 8, The second linear pushing mechanism 5 is fixedly installed on the top of the raised platform 6, the liquid guide frame...

Embodiment 2

[0064] This embodiment is basically the same as the previous embodiment, and the special features are:

[0065] In this embodiment, several liquid leakage holes are opened on the slag collecting plate 1b. When cleaning the molten aluminum with more impurities, the impurities tend to stick together due to the large amount of impurities, so the impurities will be removed by setting the leakage hole, and the molten aluminum will flow out back to the smelting cylinder 10 Inside, reducing the waste of aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com