Detection equipment and method for insulating material production

A technology of insulating materials and testing equipment, applied in the direction of analyzing materials, using stable tension/pressure testing material strength, measuring devices, etc., can solve the problems of lack of protective devices, easily damaged qualified products, easy to slide, etc., to achieve convenient application Effect of load, convenient protection, avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

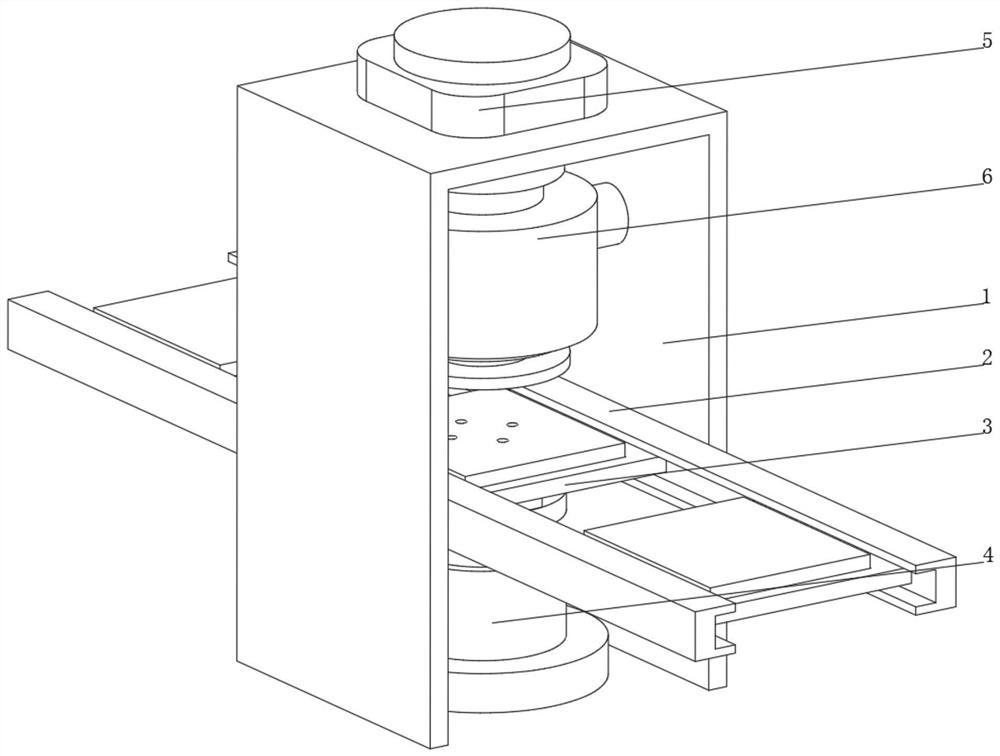

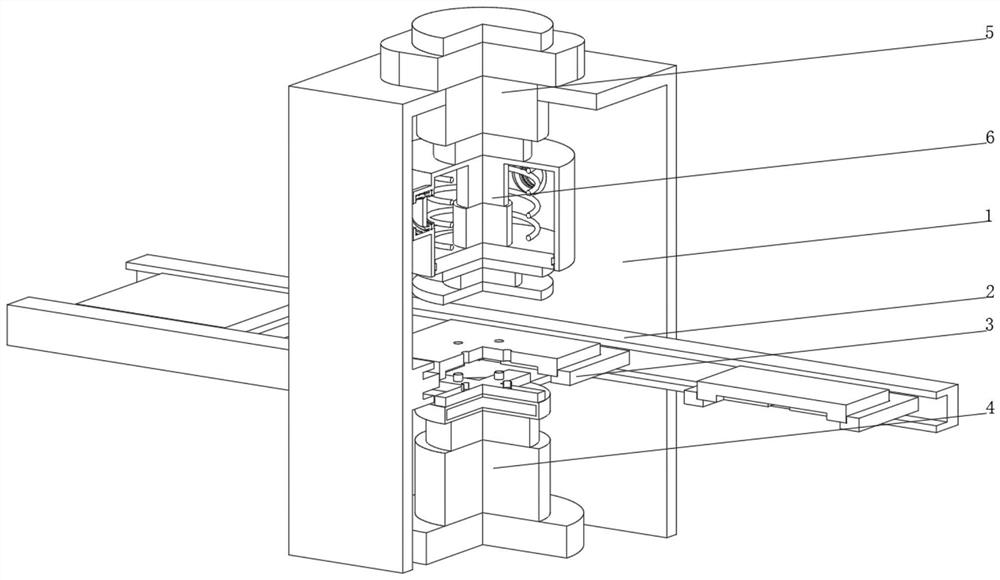

[0043] see Figure 2-4 , the present invention provides a technical solution: a detection equipment for the production of insulating materials, which specifically includes:

[0044] A bracket 1, the inner wall of the bracket 1 is fixedly connected with the transport slideway 2, and the inner wall of the transport slideway 2 is slidably connected to the transport frame 3;

[0045] A support device 4, which is arranged inside the bracket 1 and is fixedly connected to the inner wall of the bracket 1; a hydraulic push rod 5, which is arranged on the top of the bracket 1, and a detection device 6 is fixedly connected to the bottom of the hydraulic push rod 5;

[0046] The support device 4 includes:

[0047] A hydraulic ejector rod 41, the top of the hydraulic ejector rod 41 is fixedly connected with a top plate 42, and an air cavity 44 is opened inside the top plate 42;

[0048] The trachea 43, the trachea 43 is arranged on one side of the top plate 42, one end of the trachea 43 ...

Embodiment 2

[0054] see Figure 2-5 , on the basis of the first embodiment, the present invention provides a technical solution: the detection device 6 includes a sliding sleeve 61, the inner wall of the sliding sleeve 61 is slidably connected with a pressing piston 62, and the bottom of the pressing piston 62 is fixedly connected with a pressure head 63, A pressure spring 64 is fixedly connected to the top of the inner wall of the sliding sleeve 61, and the bottom of the pressure spring 64 is fixedly connected to the top of the extrusion piston 62. Both sides of the sliding sleeve 61 are connected with a control sleeve 65, and the control sleeve 65 is close to the sliding sleeve 61. The inner wall of one end is fixedly connected with a limit ring 66 , a first magnet ring 67 is connected to one side of the limit ring 66 , a second magnet ring 68 is provided on one side of the first magnet ring 67 , and the second magnet ring 68 is far away from the first magnet ring 67 A pressure sleeve 69...

Embodiment 3

[0057] see Figure 2-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the pressure sleeve 69 includes a fixing ring 691, one side of the fixing ring 691 is fixedly connected with an extrusion shell 692, and one side of the extrusion shell 692 is fixedly connected There is a control switch 693, a return spring 694 is sleeved on the outer side of the extrusion shell 692, one end of the return spring 694 is fixedly connected with the fixing ring 691, the side of the fixing ring 691 away from the return spring 694 is fixedly connected with the second magnet ring 68, and the return spring 694 The end away from the fixing ring 691 is fixedly connected to the inner wall of the control sleeve 65, the control switch 693 is electrically connected to the hydraulic push rod 5, and a pressure sleeve 69 is provided. When the first magnet ring 67 and the second magnet ring 68 are disengaged, the pressure Pushed by the air pressure, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com