Cutter for cutting glass

A glass cutting and cutting tool technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as more wear and scratches at the cutting position, and achieve the effect of precise cutting and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

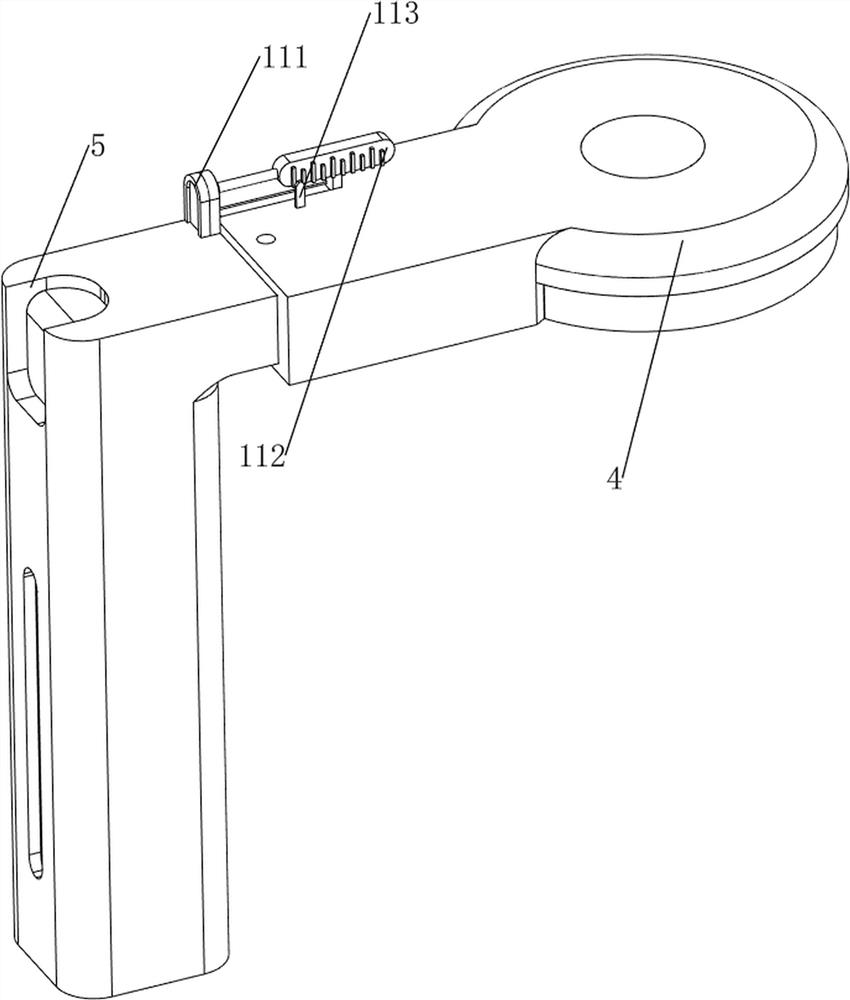

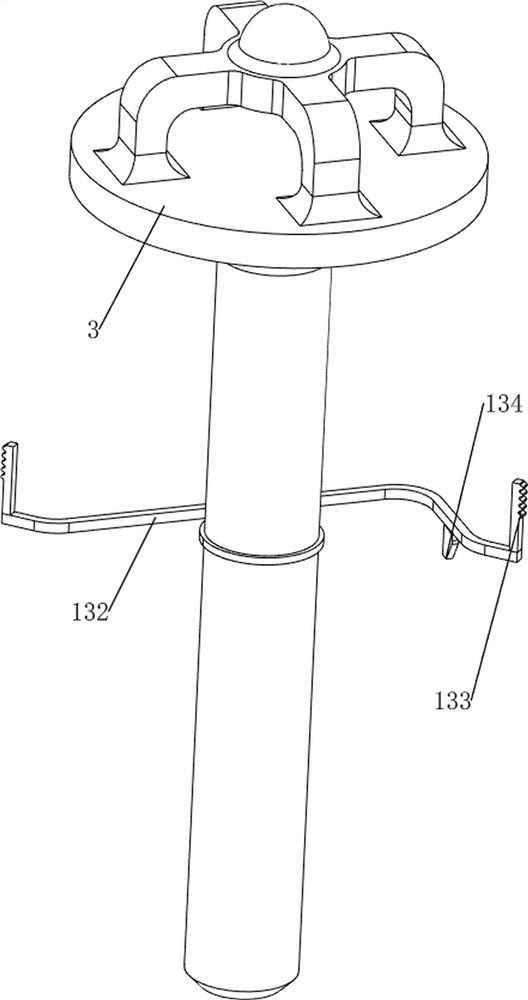

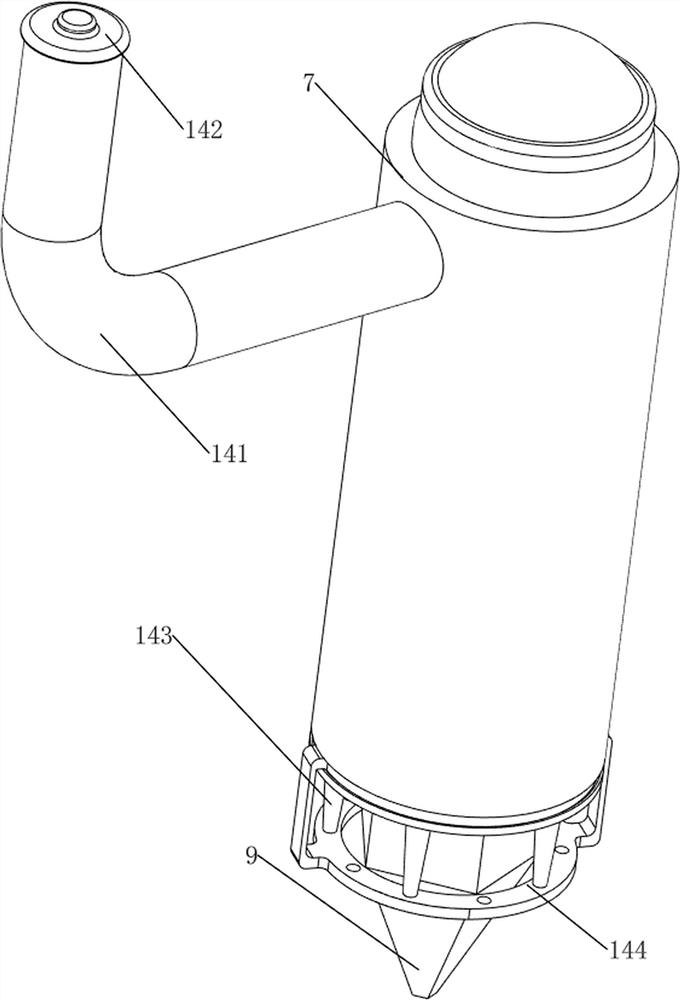

[0034] A glass cutting tool, such as Figure 1-6 As shown, it includes a first rubber 1, a support frame 2, a first fixed rod 3, a fixed frame 4, a movable frame 5, a first spring 51, a clamping rod 6, a shell 7, a sliding rod 8, a glass knife 9, a clamping Mechanism 10 and measuring mechanism 11, the lower side of the first fixed rod 3 is provided with a support frame 2, the bottom of the support frame 2 is provided with four first rubbers 1, the middle position of the first fixed rod 3 is rotatably provided with a fixed frame 4, and the fixed frame 4. The rear sliding type is provided with a movable frame 5, and the fixed frame 4 and the movable frame 5 are movablely provided with a clamping rod 6. The sliding type in the movable frame 5 is provided with a shell 7, and the shell 7 and the movable frame 5 are connected with a second A spring 51, the upper side of the casing 7 is symmetrically provided with a sliding rod 8, the sliding rods 8 are all slidably connected with th...

Embodiment 2

[0039]On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15 Shown, also comprise limit mechanism 12, limit mechanism 12 comprises the first fixed plate 121, rotating shaft 122, rotating frame 123, the 3rd spring 124, telescoping rod 125 and sponge 126, on the first fixed rod 3 rotary type There is a first fixed plate 121, the first fixed plate 121 is located on the upper side of the fixed frame 4, the first fixed plate 121 is provided with a rotating shaft 122 symmetrically rotated, and the rotating frame 122 is provided with a rotating frame 123, and the upper side of the rotating frame 123 slides The formula is provided with telescopic rod 125, and the ends of telescopic rod 125 are all provided with sponge 126, and the third spring 124 is all connected between telescopic rod 125 and rotating frame 123.

[0040] The user can rotate the rotating shaft 122 on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com