Operation method for melting squatting furnace steel body by medium-frequency induction steel melting furnace

An operation method and steel body technology, applied in the field of metal casting metallurgy, can solve the problems of broken furnace body, unable to remelt and cool the steel body in the furnace, molten steel leakage and explosion, etc., so as to save production costs and avoid furnace construction Furnace manpower cost and the effect of saving furnace charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

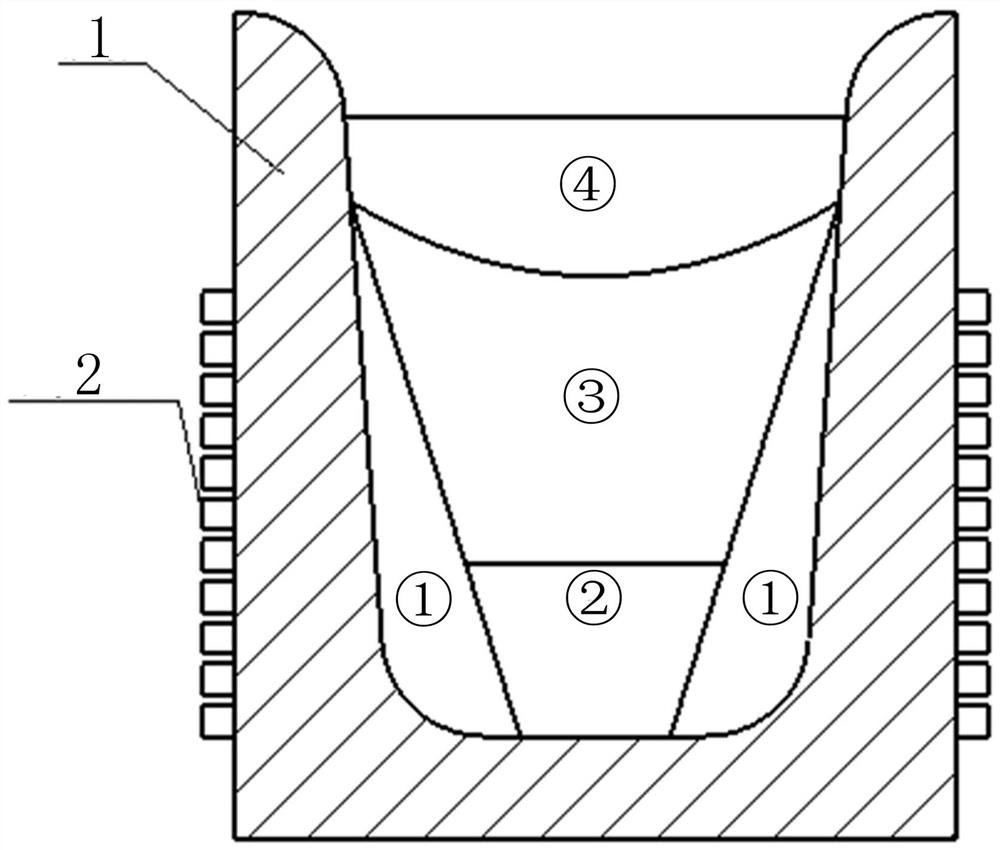

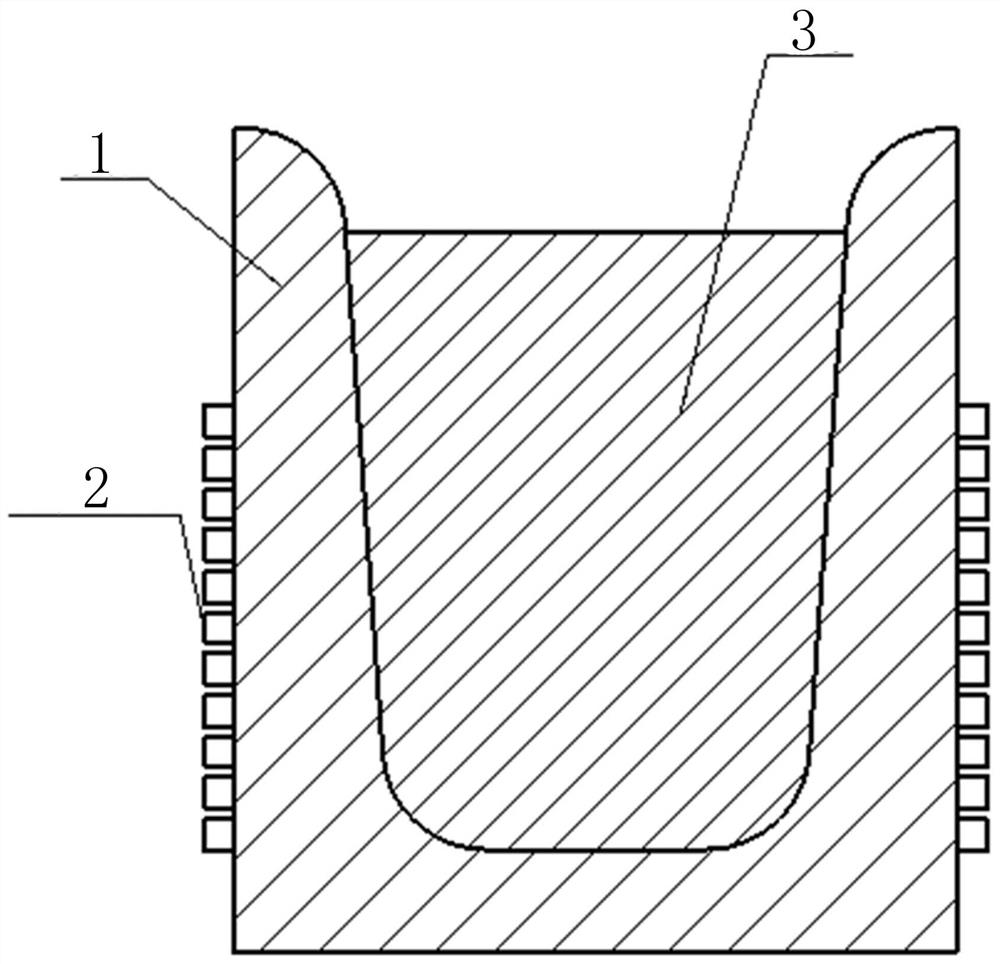

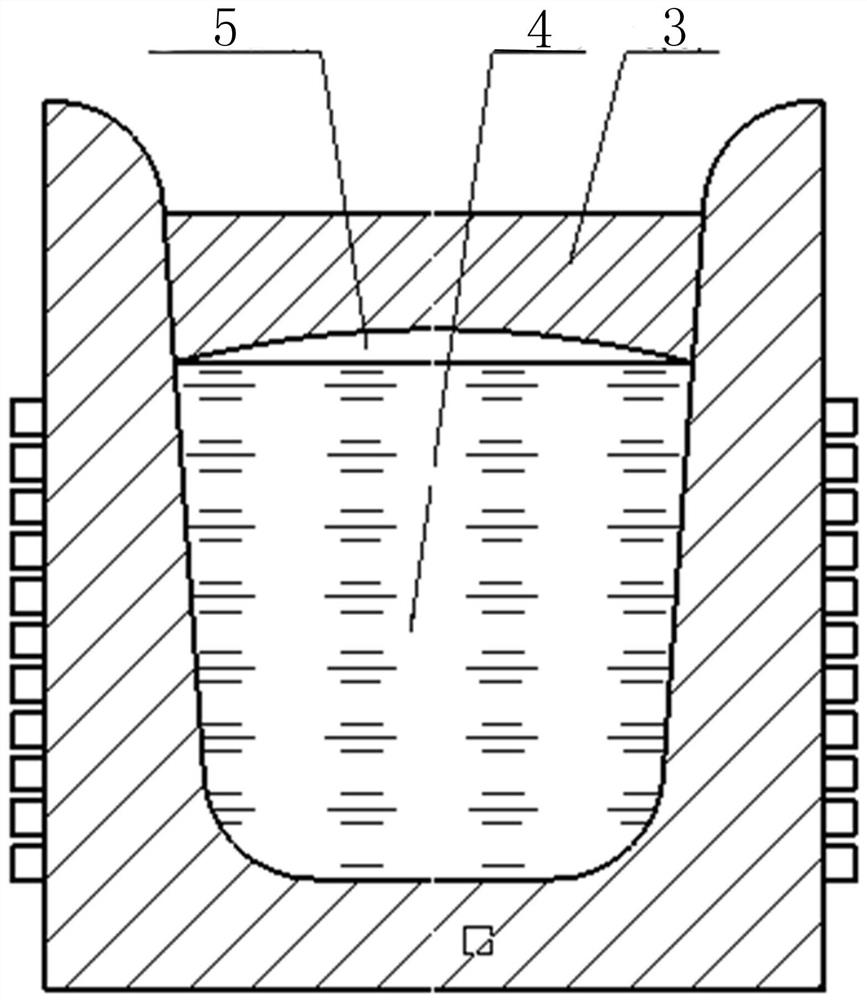

[0026] The present invention adopts the technical measures of tilting furnace melting to realize the melting of the squat furnace steel body, as attached Figure 4 As shown, the specific operation method is as follows:

[0027] 1) Preparation: Check the furnace body and the steel body of the squatting furnace to ensure that there is no abnormality.

[0028] 2) Power transmission: According to the requirements of melting operation, power transmission is used to melt the steel body, and the current adopts high current.

[0029] 3) Tilt the furnace: After 20-40 minutes of melting, tilt the furnace at 60 to 80 degrees.

[0030] 4) Remelting: Continuously observe the surface of the steel body. When the surface of the steel body is red and bright red, and there is metal cremation, slightly return to the furnace.

[0031] 5) Poke the furnace: located on the side of the furnace body, gently poke the reddish and brightest part of the steel body with a steel drill. When the steel dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com