Power distribution system of direct current charging equipment and direct current charging equipment

A DC charging and distribution system technology, applied in charging/discharging current/voltage regulation, charging stations, battery circuit devices, etc., can solve the problem of a single power distribution mode, and achieve multiple power distribution modes, convenient control, and overall balance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

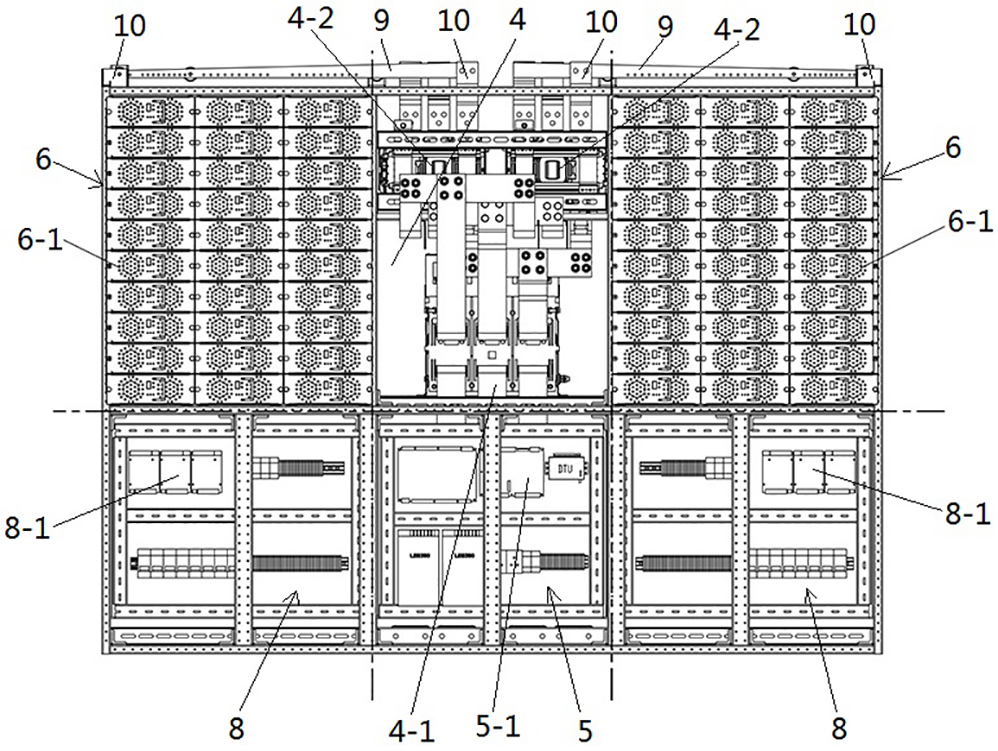

[0050] The DC charging equipment is used in a split DC charging station in the form of a whole station, including a host and a charging pile, and a charging gun is provided on the charging pile. Among them, the host is used to realize AC-DC conversion and power distribution to form a power distribution system; the charging pile adopts a distributed layout to form a charging terminal (such as Figure 7 No. 1 sub-pile, No. 2 sub-pile ... No. 15 sub-pile); each charging post includes two charging guns, and each charging gun is connected to the DC charging device through the corresponding power supply circuit 12, located at Figure 7 The top is the first power supply circuit 12, which is located at Figure 7 The top one is the power supply circuit 12 at the end.

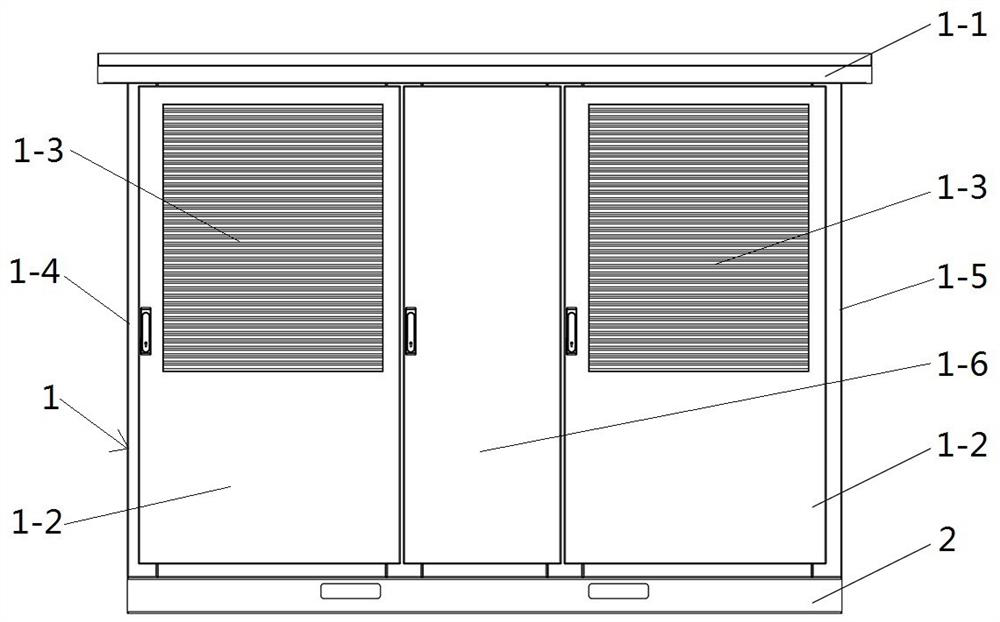

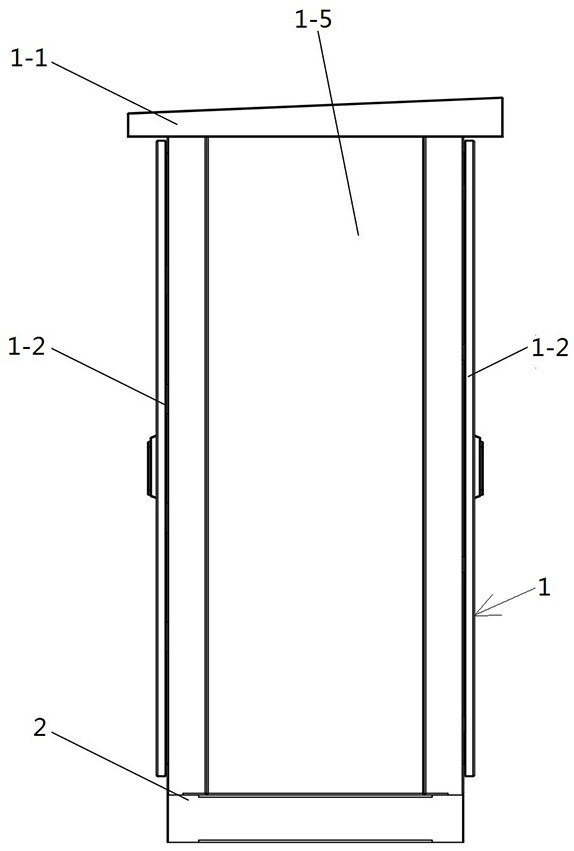

[0051] like figure 1 and figure 2 As shown, the host of the DC charging equipment adopts the form of a charging cabinet, including a base 2 and a cabinet 1, wherein the cabinet 1 is installed on the base 2, and the c...

Embodiment 2

[0079] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, all the power modules in any group of homologous power supply groups are controlled as a whole through the module input contactors corresponding to the group of power modules, while this In the embodiment, each power module is individually controlled through a single-module contactor corresponding to each power module.

Embodiment 3

[0081] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the homologous power supply group is divided into two groups, while in this embodiment, each module group includes two power modules, and the homologous power supply group is divided into three groups. . Of course, in other embodiments, the same-source power supply group can also be divided into more than four groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com