Full-closed negative pressure type automatic grain sorting machine

An automatic sorting, negative pressure technology, applied in the separation method, dispersed particle separation, dispersed particle filtration, etc., can solve the problem that the grain cannot be directly stored and used, the agglomerated grain cannot be inhaled, and the grain sorting intensity is reduced, etc. problem, to achieve the effect of improving the suction effect, avoiding the suction effect, and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

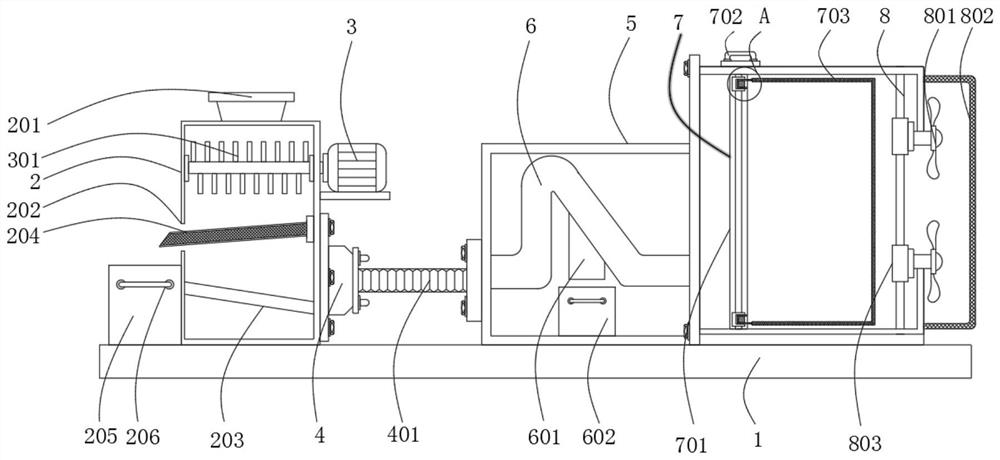

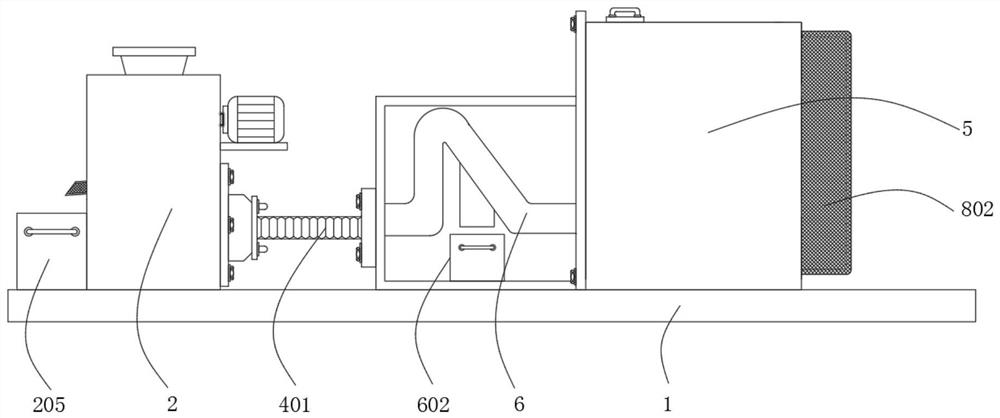

[0024] Example 1, such as Figure 1-3 As shown, the present invention provides a fully enclosed negative pressure automatic grain sorting machine, comprising a bottom plate 1, characterized in that: a pretreatment box 2 is welded above the bottom plate 1, and one side of the outer surface of the pretreatment box 2 is passed through a bolt A sealing port 4 is fixedly communicated, and a connecting pipe 401 is fixed on one side of the sealing port 4, and one end of the communicating pipe 401 is sealed and communicated with a casing 5, and the casing 5 is fixed on the top of the bottom plate 1 by bolts, and the inner surface of the casing 5 A fixed structure 7 is installed, and a suction structure 8 is fixed on one side of the casing 5 .

[0025] Let's talk about the specific settings and functions of the fixed structure 7, the pretreatment box 2 and the suction structure 8 below.

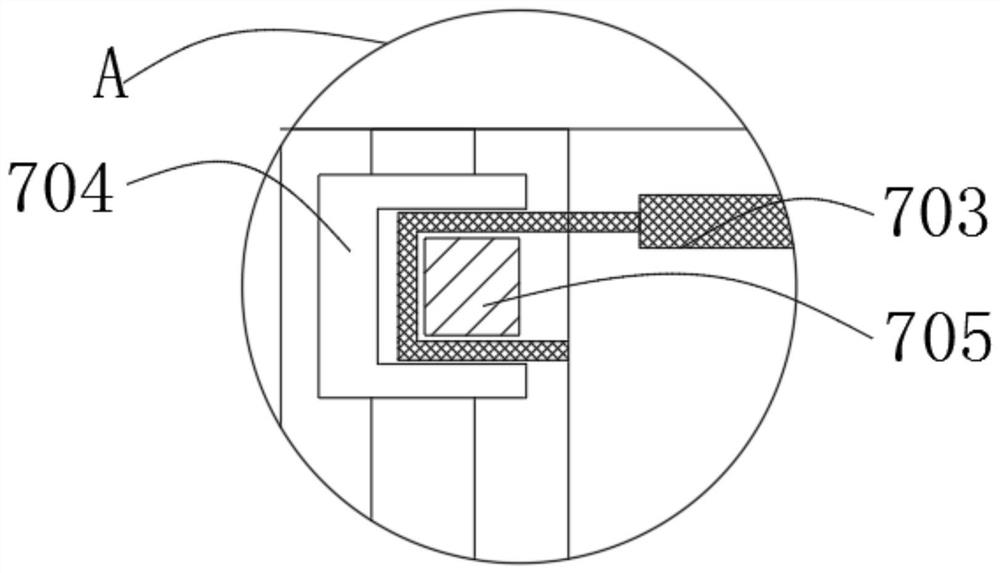

[0026] Such as figure 1 , image 3 and Figure 4 As shown, the interior of the fixed structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com