Tool storage management device

A technology for managing devices and tools, applied in tool storage devices, manufacturing tools, workshop equipment, etc., can solve problems such as low tool utilization, inability to pick up tools, and high risk of tool loss, so as to reduce production preparation time and prevent abnormal Authorized personnel to receive the effect of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0033] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

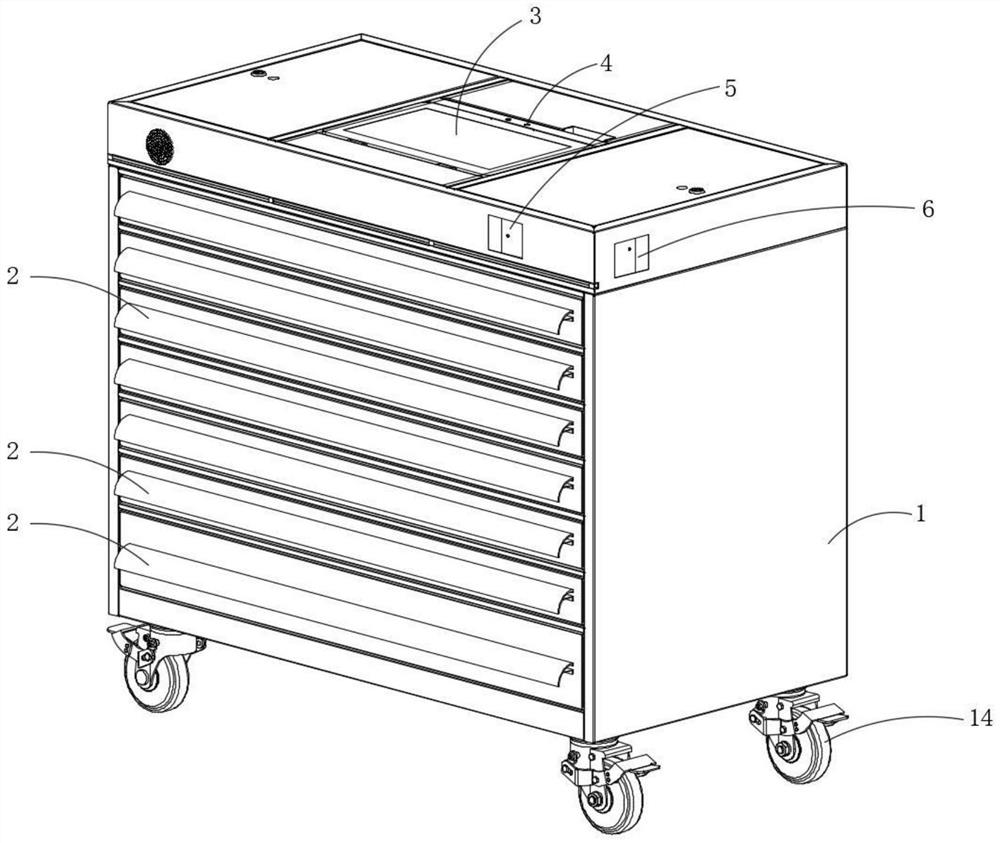

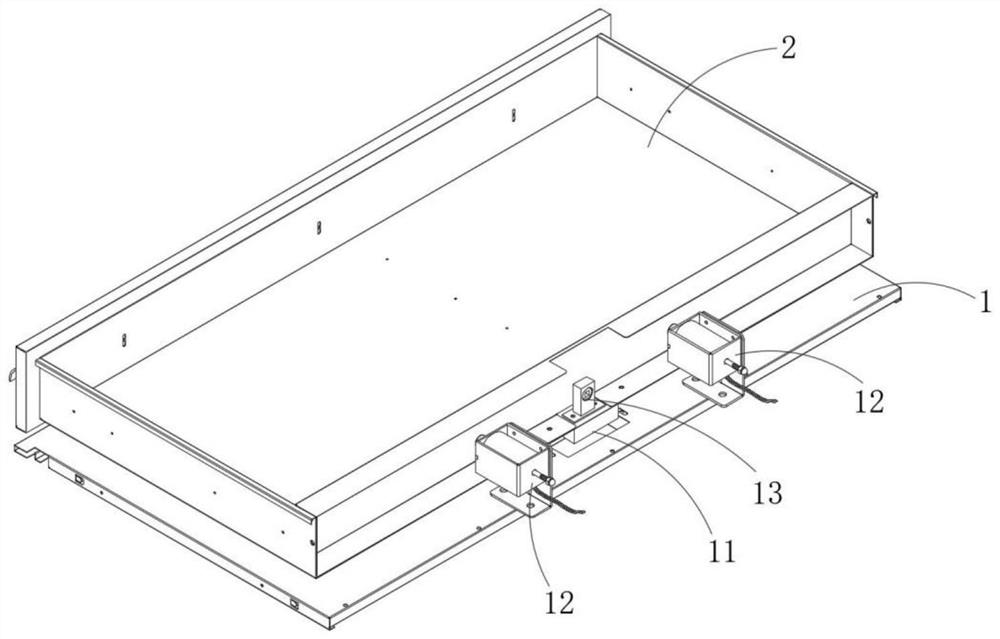

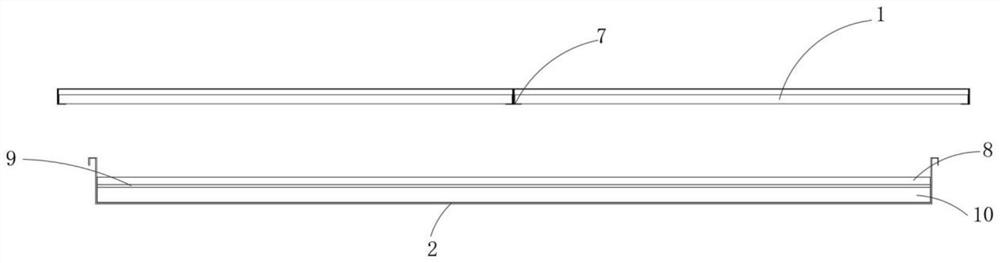

[0034] Such as Figure 1-Figure 4 As shown, a tool storage management device provided in an embodiment of the present invention includes a tool cabinet and a storage management system. The tool cabinet includes a box body 1 and a plurality of drawers 2 horizontally slidingly arranged in the box body 1. The drawer 2 is used to place tools. Each drawer 2 can place different tools. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap