Transverse bulkhead structure for large LNG (liquefied natural gas) ship

A technology for LNG ships and transverse bulkheads, which is applied in the field of transverse bulkhead structures, can solve problems affecting structural design, etc., and achieve the effects of increasing effective space, improving convenience, and facilitating traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

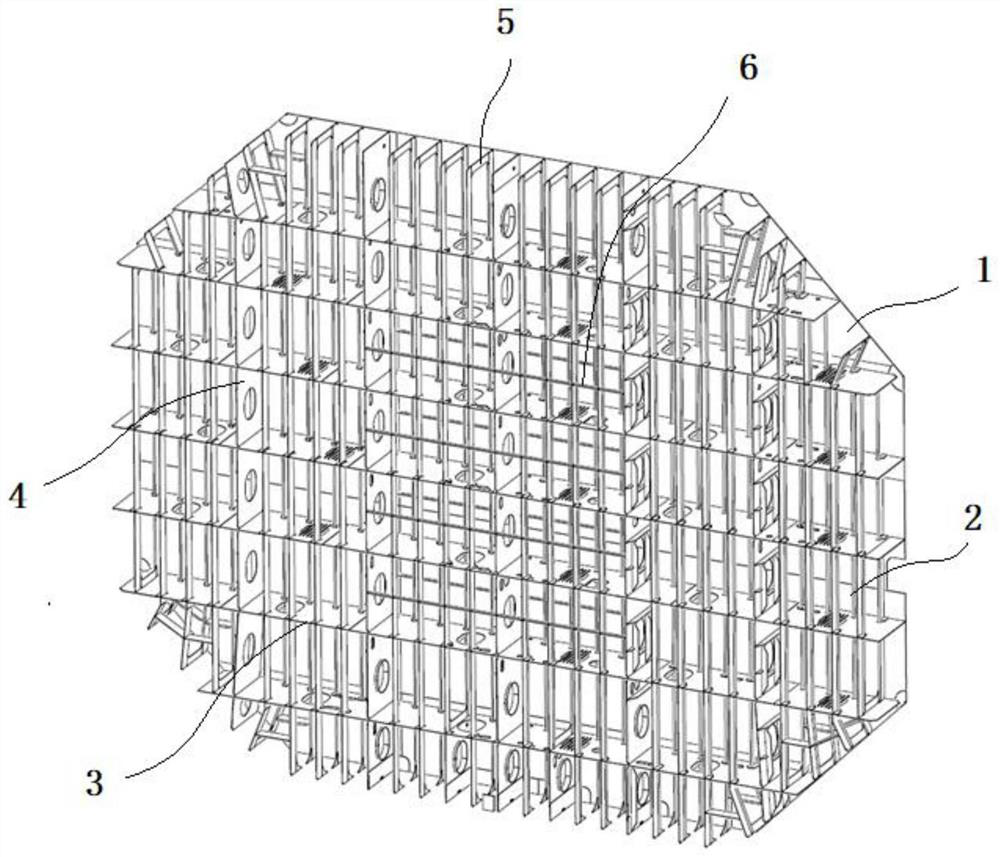

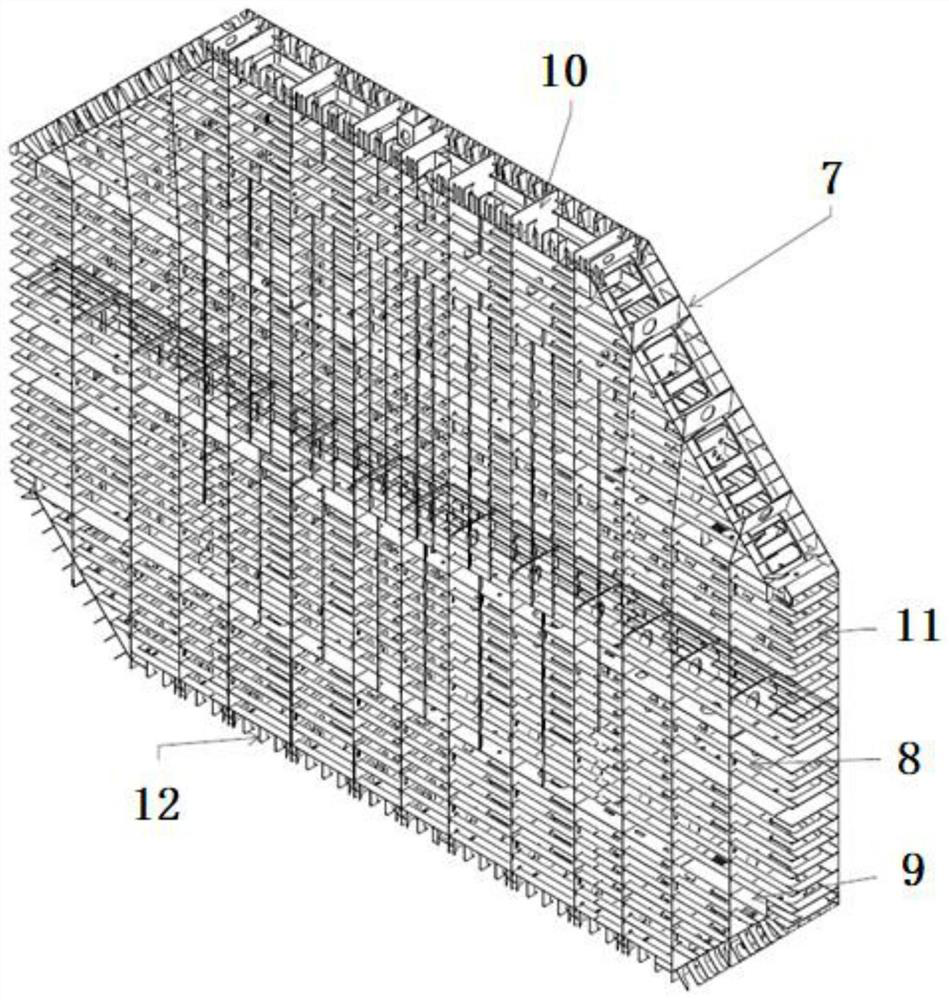

[0022] Below we will further elaborate on the transverse bulkhead structure used on the large LNG ship of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand its structural composition and working method more clearly, but this cannot be limited by this protection scope of the invention.

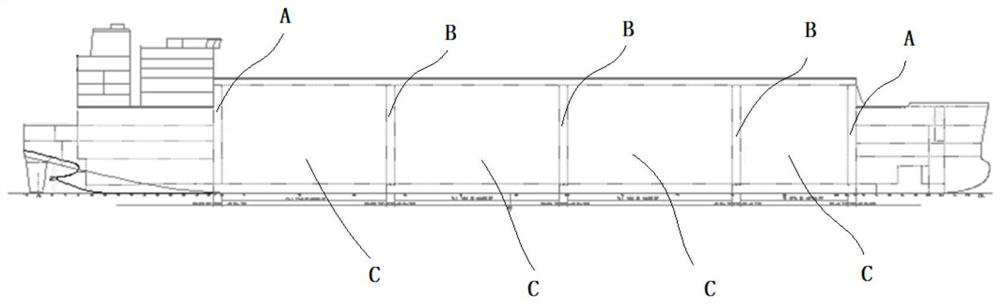

[0023] The invention is used as a transverse bulkhead structure on a large LNG ship. The large-scale LNG ship is equipped with a liquefied natural gas containment system. The containment system is provided with a plurality of liquid cargo tanks C, and a vertically arranged transverse compartment A is arranged between the bow area and the liquid cargo tanks C. In the midship area A horizontally arranged transverse compartment B is provided between adjacent cargo tanks C, and a vertically arranged transverse compartment A is provided between the stern area and the cargo tank C. Such as figure 1 As shown, the containment system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com