Iron and steel metallurgical furnace capable of intelligently identifying faults

A technology of iron and steel metallurgy and intelligent identification, which is applied in the field of iron and steel metallurgical furnaces, can solve problems such as loading wrong materials, mixing in metallurgical furnaces, and affecting the quality of metallurgical liquids in metallurgical furnaces, and achieve the effect of improving practical value and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

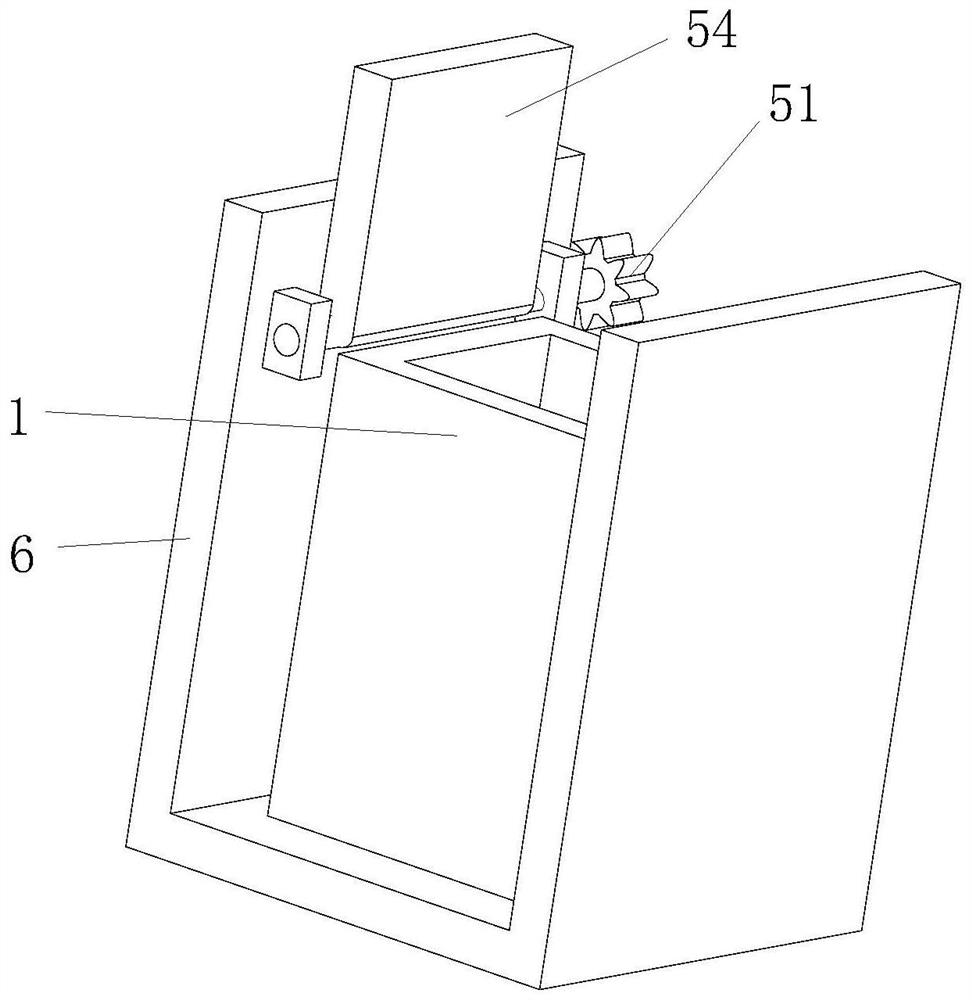

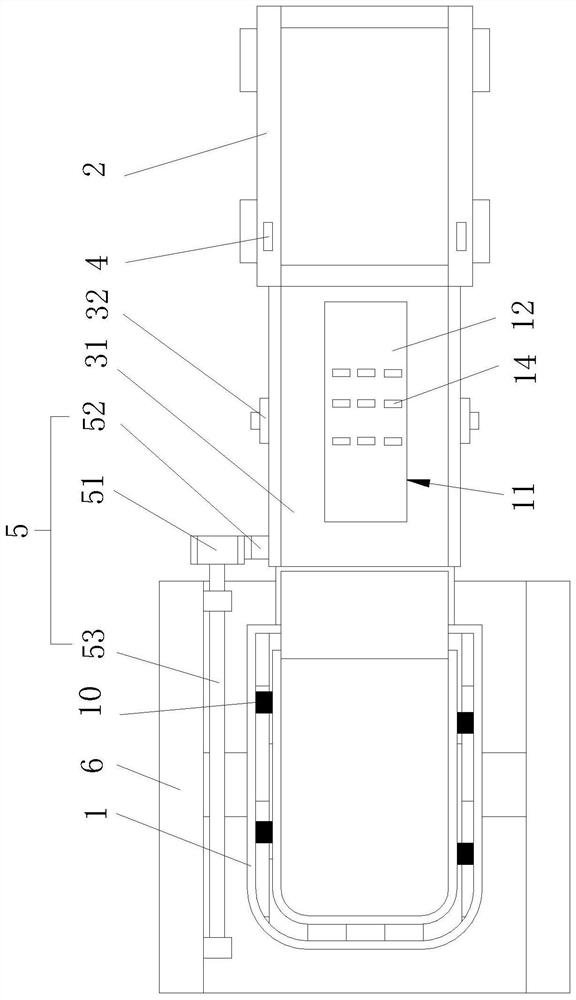

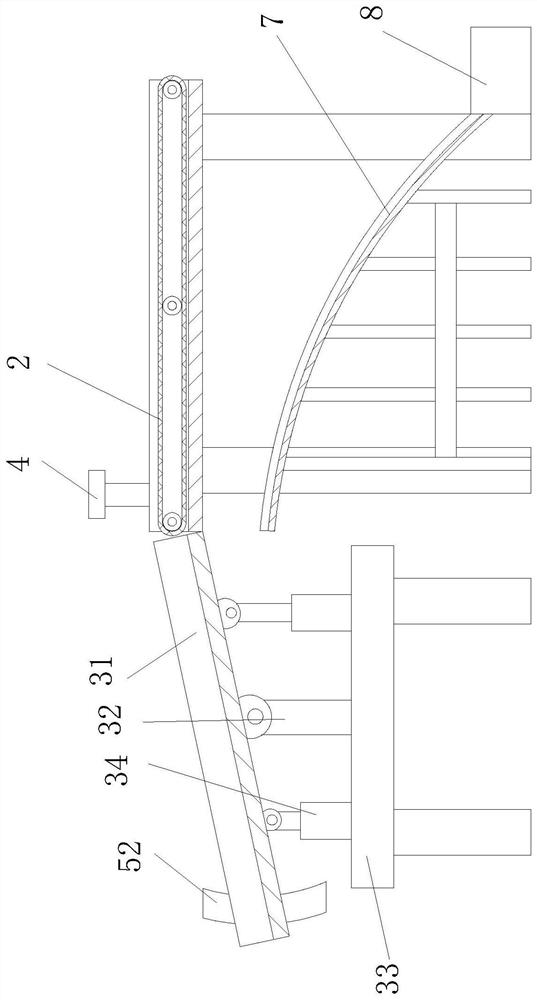

[0030] Attached below Figure 1-7 The present invention is further described with embodiment:

[0031] An iron and steel metallurgical furnace capable of intelligently identifying faults, comprising a mounting frame 6, a furnace body 1 is arranged in the mounting frame 6, a temperature measuring layer is also arranged in the furnace body 1, and a monitoring mechanism is arranged in the temperature measuring layer 10. A conveying mechanism 2 is arranged on one side of the furnace body 1, a discharge mechanism 3 is arranged between the conveying mechanism 2 and the furnace body 1, and an identification device 4 is arranged on the conveying mechanism 2, and the identification device 4 is used to identify materials; The invention solves the problem that when the iron and steel metallurgical furnaces on the market are in use, manual feeding is often used by workers, and wrong materials are prone to occur, resulting in the mixing of other materials in the metallurgical furnace and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com