Single-side floating eliminating structure of rotating shaft

A rotating shaft and unilateral technology, applied in the field of rotating shaft floating elimination structure, can solve the problems of radial and axial interference, affecting the effect of rotating shaft elimination, unstable use, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

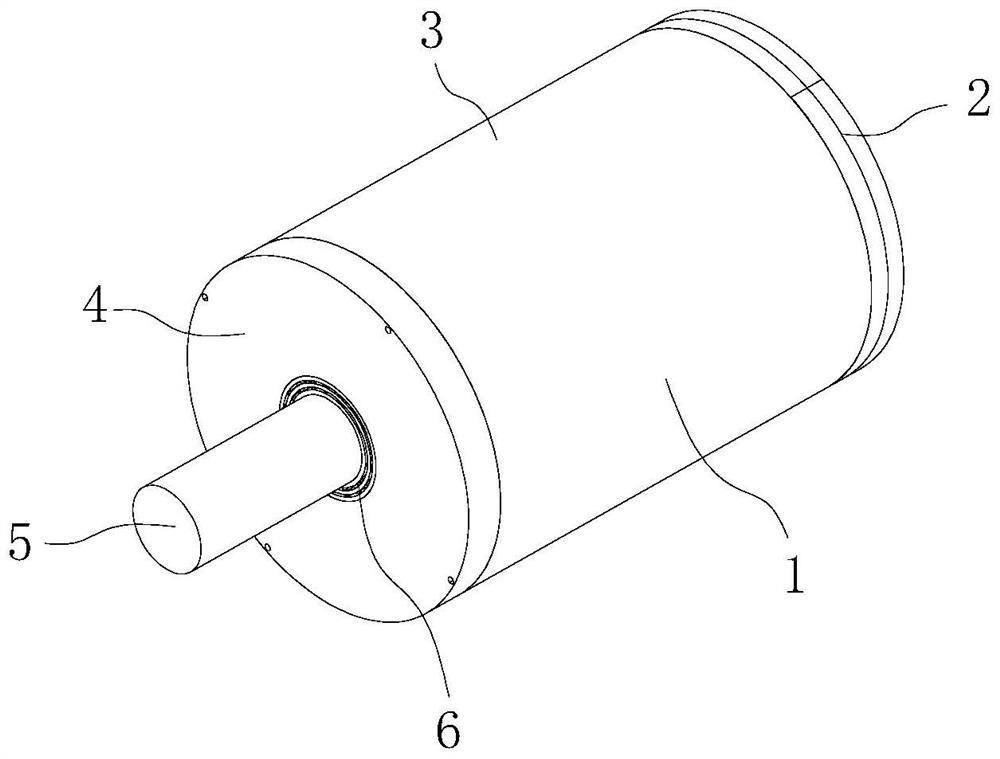

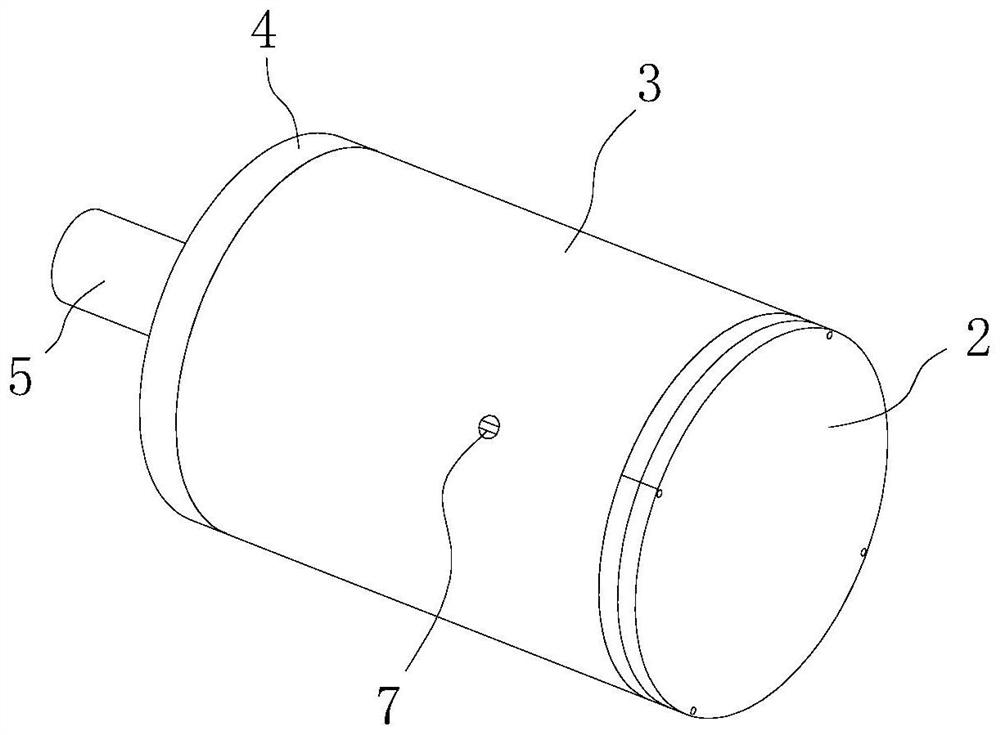

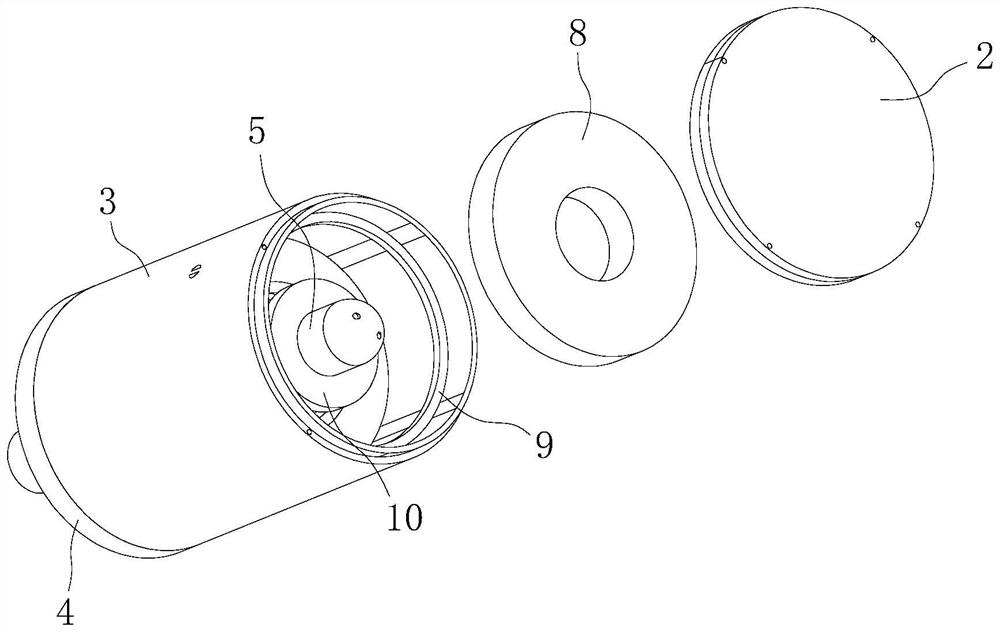

[0041] Figure 1-Figure 9 As shown, the floating elimination structure on one side of the rotating shaft includes a rotating shaft 5 , a magnetic attraction device 8 , an axial supporting member 20 and at least two sets of bearings 6 .

[0042] The rotating shaft 5 is rotatably arranged on the support 25. Preferably, the support 25 is the electric spindle casing 1, and the electric spindle casing 1 is a component on the existing electric spindle.

[0043] figure 1 , figure 2 , Figure 4 As shown, the above-mentioned rotating shaft 5 is arranged in the electric spindle casing 1, and the end of the front end of the rotating shaft 5 passes through the electric spindle casing 1. Specifically, the electric spindle casing 1 includes a main casing 3 and a main casing connected to the main casing. The front end cover 4 at the front end of the body 3, the front end cover 4 is fixedly connected to the front end of the main housing 3 by screws, the center of the front end cover 4 is ...

Embodiment 2

[0073] Figure 10-Figure 13 As shown, the floating elimination structure on one side of the rotating shaft includes a rotating shaft 5 , a magnetic attraction device 8 , an axial supporting member 20 and at least two sets of bearings 6 .

[0074] The rotating shaft 5 is rotatably arranged on the support 25. Preferably, the support 25 is the electric spindle casing 1, and the electric spindle casing 1 is a component on the existing electric spindle.

[0075] The above-mentioned rotating shaft 5 is arranged in the electric spindle casing 1, and the end of the front end of the rotating shaft 5 passes through the electric spindle casing 1. Specifically, the electric spindle casing 1 includes a main casing 3 and a front end connected to the main casing 3. The front end cover 4 is fixedly connected to the front end of the main housing 3 by screws, the center of the front end cover 4 is provided with a through hole 11, and the rotating shaft 5 in the electric spindle casing 1 is conn...

Embodiment 3

[0105] Figure 14 As shown, the rotating shaft 5 in the above embodiment can also be a screw rod, and the axial floating of the screw rod can be eliminated through the mutual cooperation of the above-mentioned blocking member 18 and the axial support member 20, and the friction suffered by the screw rod when rotating can be reduced. force, through at least two sets of bearings 6 set on the screw rod to eliminate the radial floating of the screw rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com