Automatic tree correcting device

An automatic and arboreal technology, applied in gardening tools/equipment, gardening, agriculture, etc., can solve the problems of difficult correction, automatic loosening and falling of ropes, etc., to reduce the cost of manual management, prevent reverse bending, and prevent loosening and falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

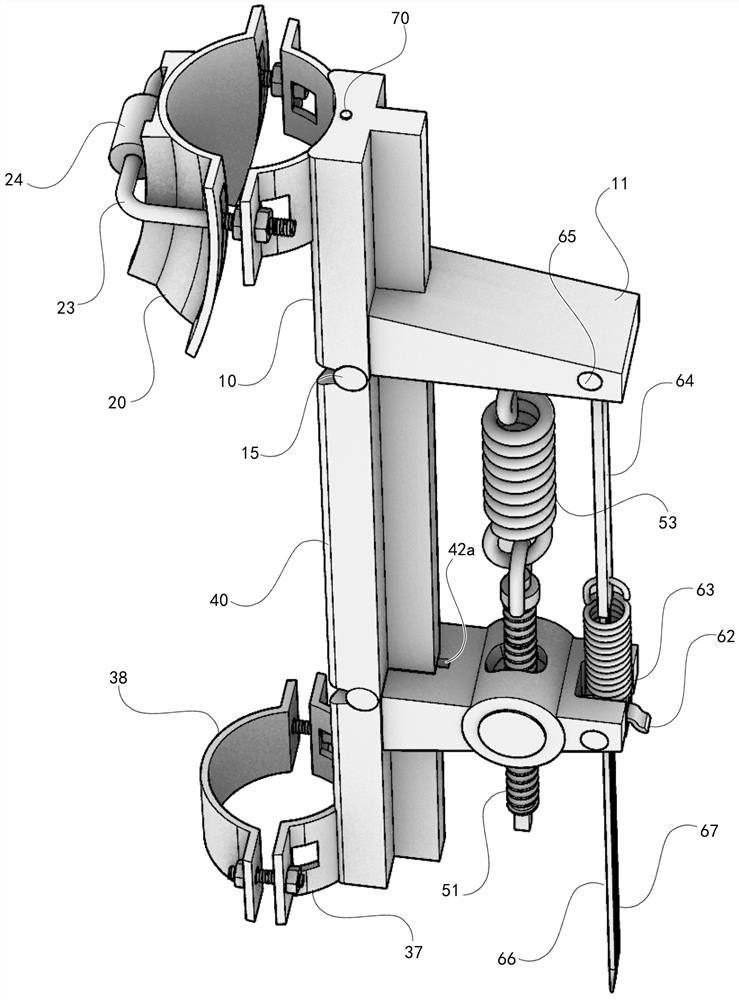

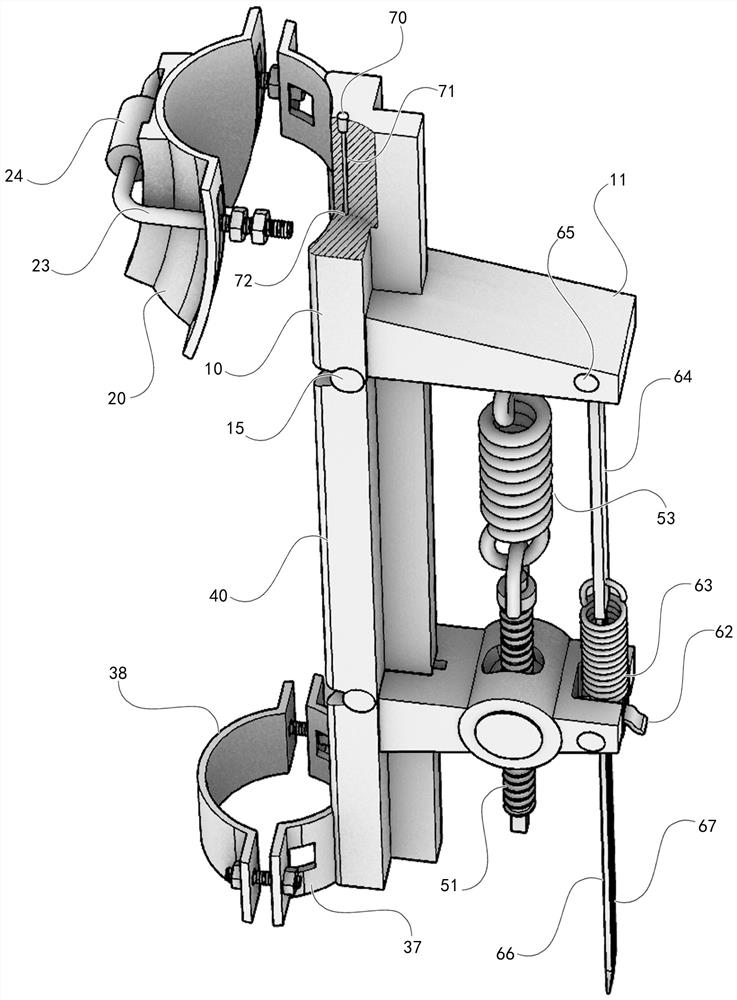

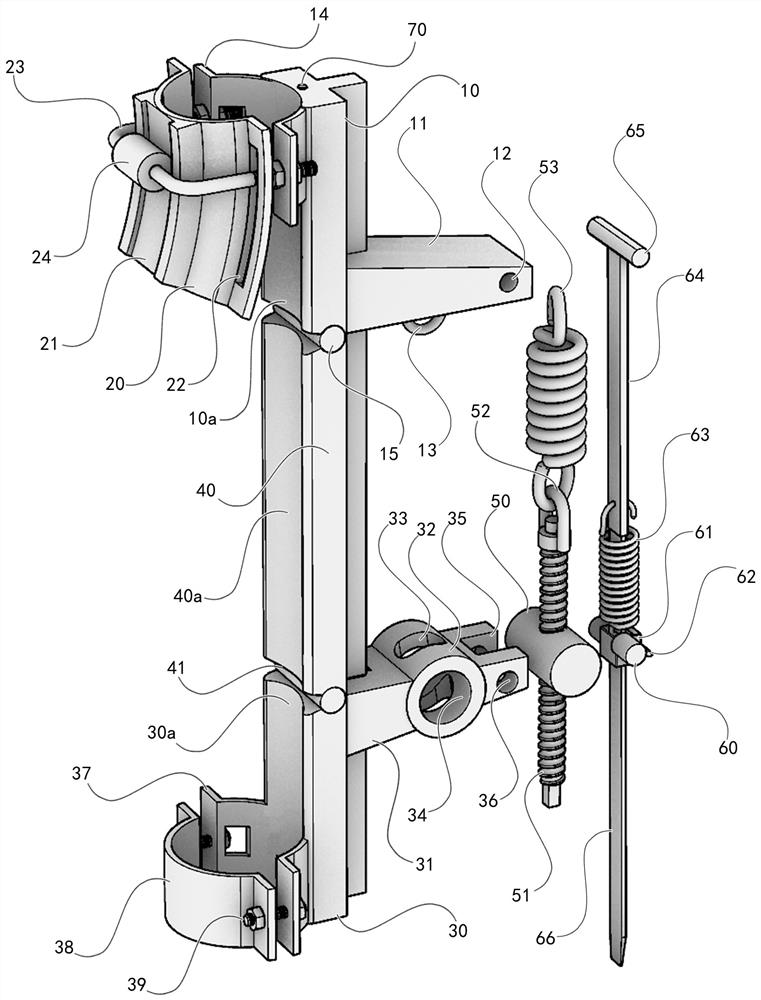

[0022] like Figure 1 to Figure 4 Shown, a kind of automatic straightening device for trees comprises a first fixed frame 10, a movable collar 20, a second fixed frame 30, an intermediate support 40, a second rotating shaft 50, a third rotating shaft 60, and a stop head 70; it is characterized in that , the first fixed frame 10 is provided with a first arc surface 10a, a first ferrule 14, a first fixed frame rotating shaft 15, a first limiting groove 43a and a first bracket 11, and the first bracket 11 is provided with a first A shaft hole 12 and annulus 13; a rolling groove 21 and a strip hole 22 are arranged on the movable ring 20; a bearing 24 is arranged in the middle of the U-bolt 23; a second arc surface 30a, a second Two limit grooves 42a, the third ferrule 37 and the second bracket 31; the top of the second bracket 31 is provided with a U-shaped groove 35, and the third shaft hole 36 runs through the U-shaped groove 35; the middle section of the second bracket 31 is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap