Beam construction method of bridge-tunnel collaborative construction structure

A construction method and bridge-tunnel technology, applied in bridges, bridge applications, bridge construction, etc., can solve the problems of time-consuming, labor-intensive, raising, waste of building materials and construction costs, and achieve shortened construction period, clear structural force transmission route, and efficient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

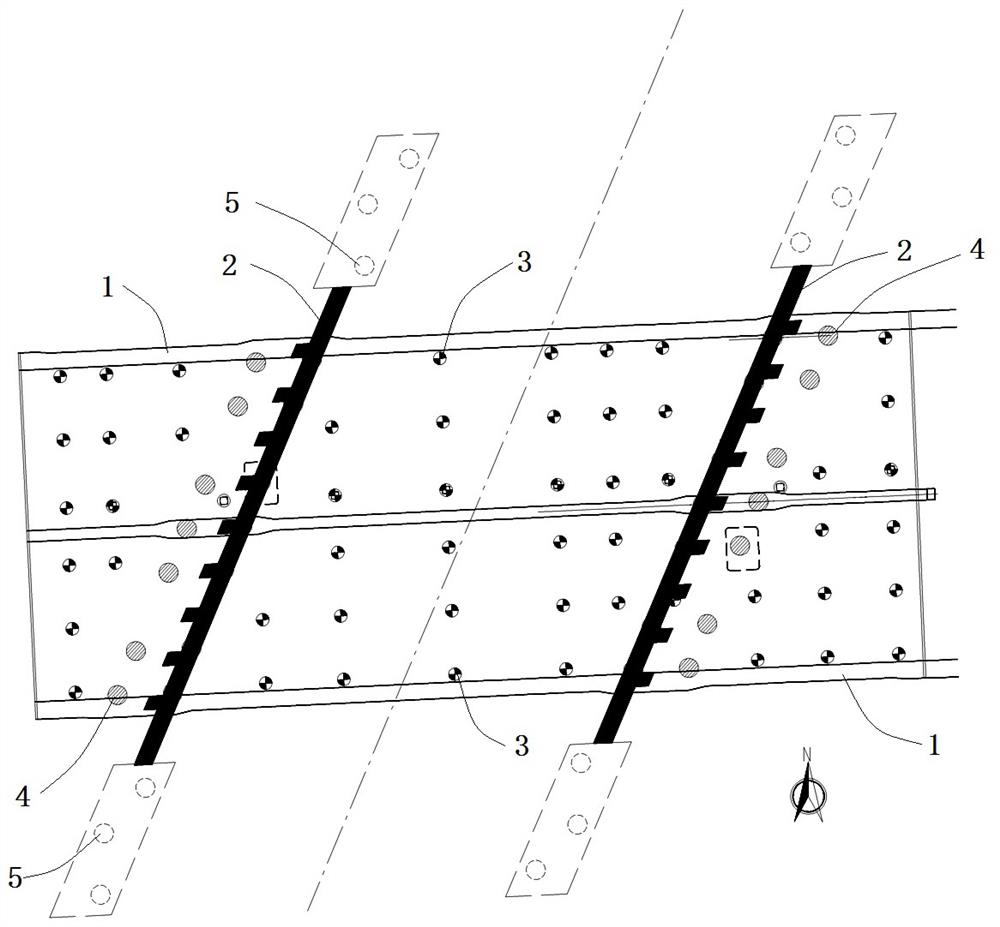

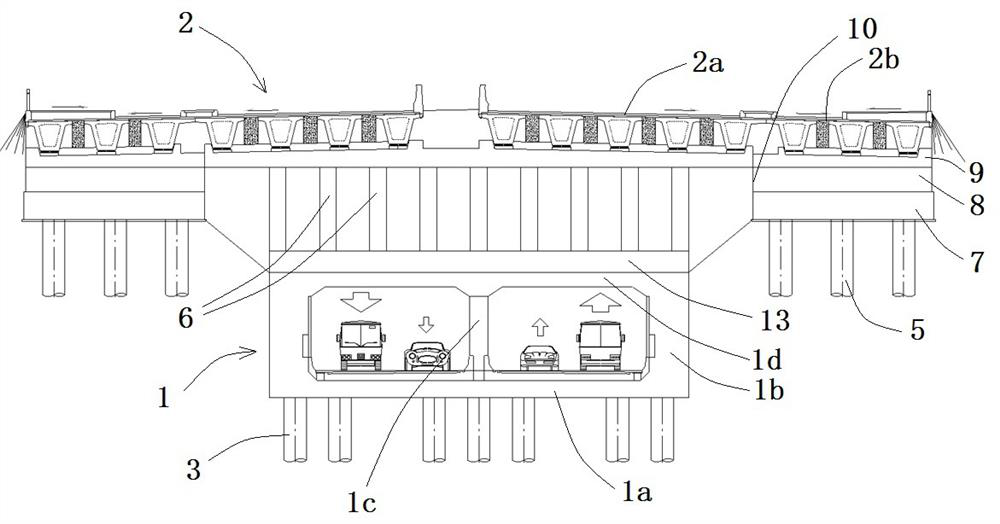

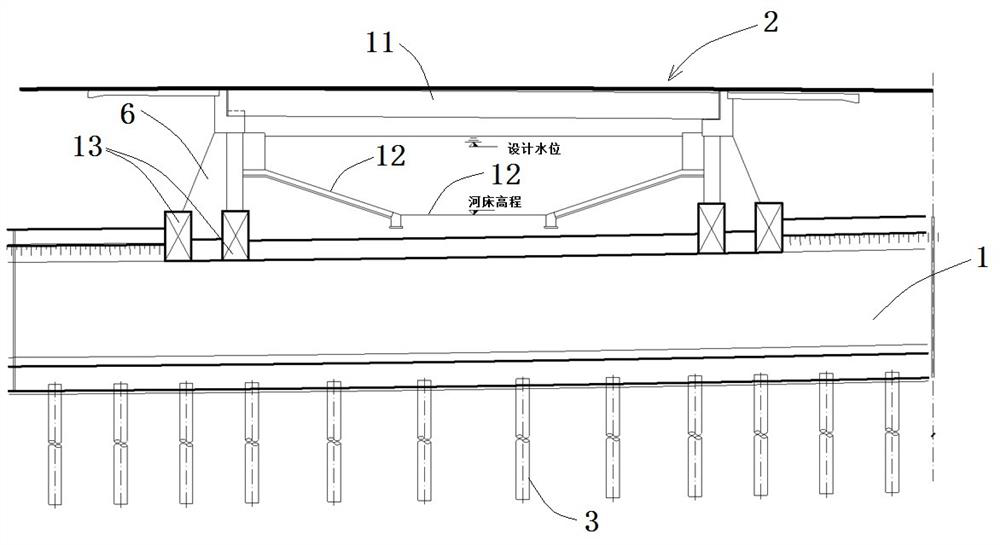

[0032] Example: such as figure 1 , 2 , 3, and 4, the present embodiment specifically relates to a beam construction method for a bridge-tunnel collaborative construction structure, and the beam construction method mainly includes the following steps:

[0033] (1) At the beginning of the dry season, set up a diversion open channel on the upstream side of the river to divert the river, and renovate the river according to the planned section 12 of the riverbed; the bridge 2 to be constructed and the tunnel 1 to be constructed are obliquely intersected in the river area , and across the riverbed 12, the tunnel 1 is located under the main girder 11 of the bridge 2, the tunnel 1 is a double-hole box culvert structure, the tunnel 1 and the bridge 2 are constructed at the same time, and the stress and deformation are coordinated;

[0034] A circle of foundation pit enclosure structure is set in the river channel area to be constructed, and tunnel uplift piles 3, bridge piles 4 and br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com