110KV double-loop T connection steel pipe pole

A steel pipe pole and double-circuit technology, applied in the field of steel pipe poles, can solve problems such as inconvenience, high investment costs, and complex force on the foundation, and achieve the effects of clear structural force transmission routes, large footprint, and optimized cross-arm size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

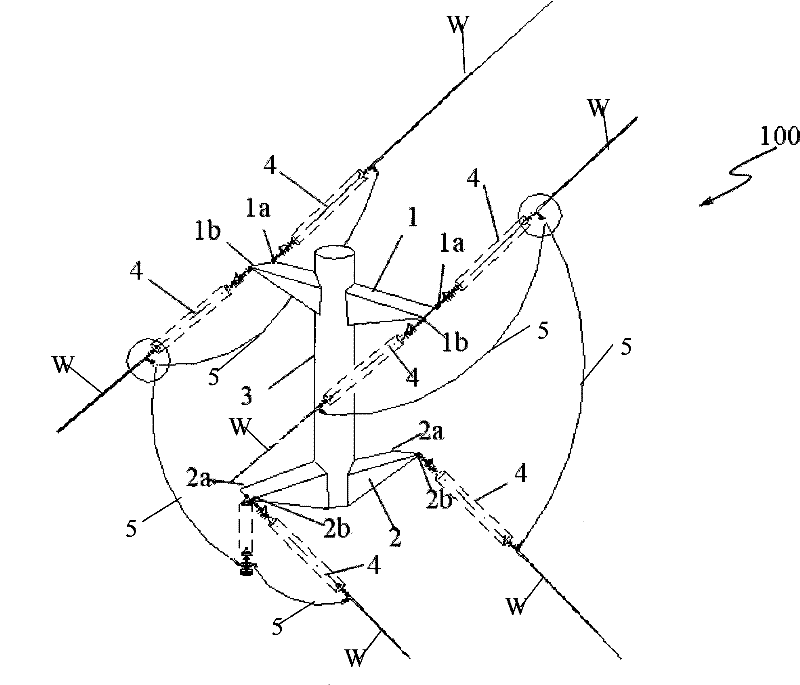

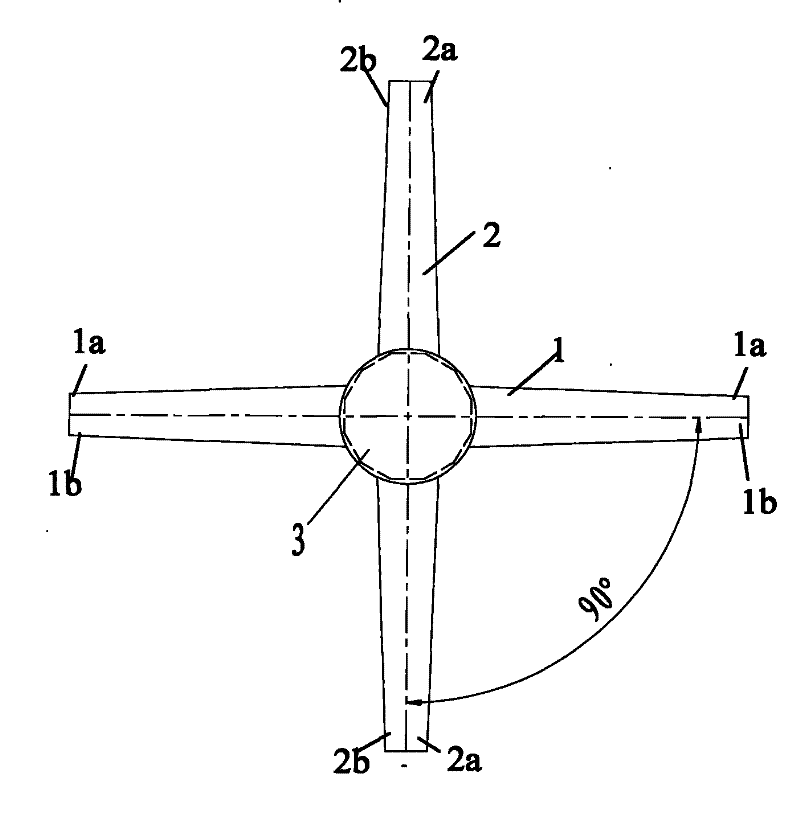

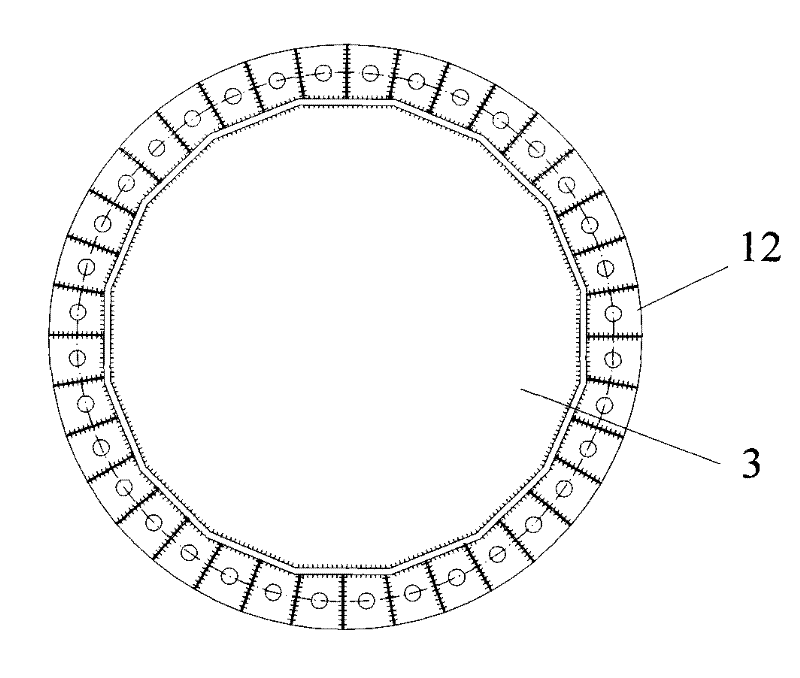

[0015] figure 1 Shown is a front view of a 110KV double-circuit T-connected steel pipe pole according to an embodiment of the present invention. figure 2 shown as figure 1 The top view of the connection of the main rod, the main line cross arm and the T connection cross arm of the 110KV double circuit T connection steel pipe pole. Please refer to figure 1 , The double-circuit T-connected steel pipe pole 100 includes a main pole 3 , a main line cross arm 1 and a T-connected cross arm 2 . The main line cross arm 1 and the T-connection cross arm 2 are installed on the main pole 3, and the T-connection cross arm 2 and the main line cross arm 1 are spatially arranged in layers and form an included angle.

[0016] figure 2 Shown is a top view of the connection of the main ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com