Light-steel damping composite wallboard

A composite wall panel and damping technology, which is applied to walls, building components, and earthquake resistance, can solve problems such as long construction and installation periods, difficult maintenance and replacement, and complicated processing techniques, so as to improve safety and reliability, reduce construction costs, and apply wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention will be described in further detail below in conjunction with the accompanying drawings.

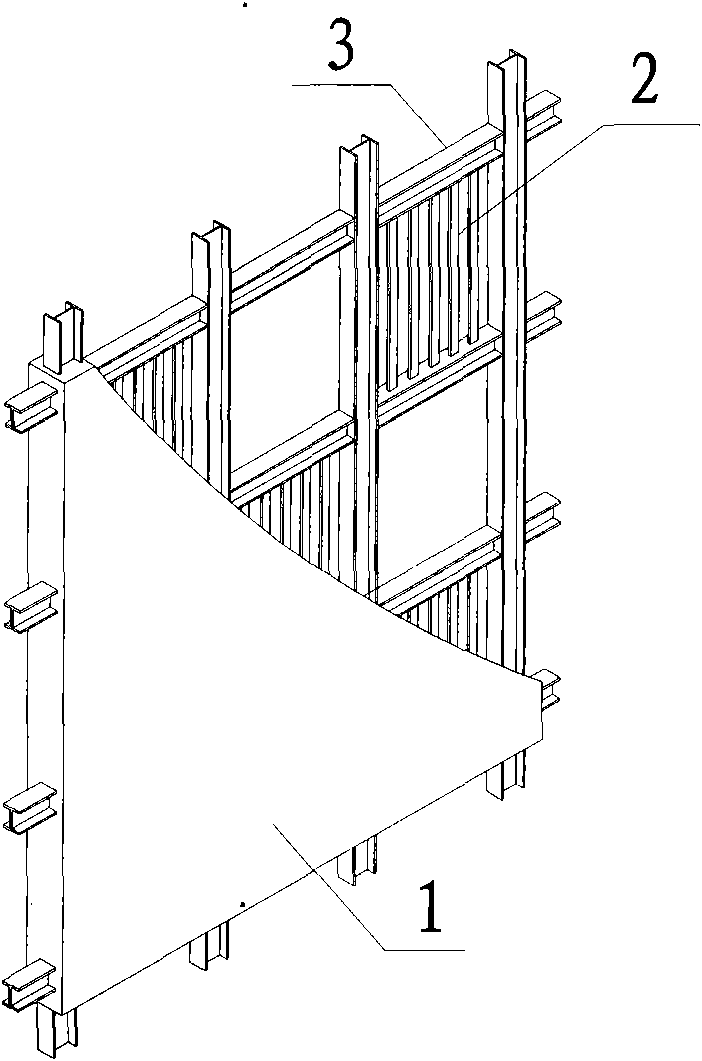

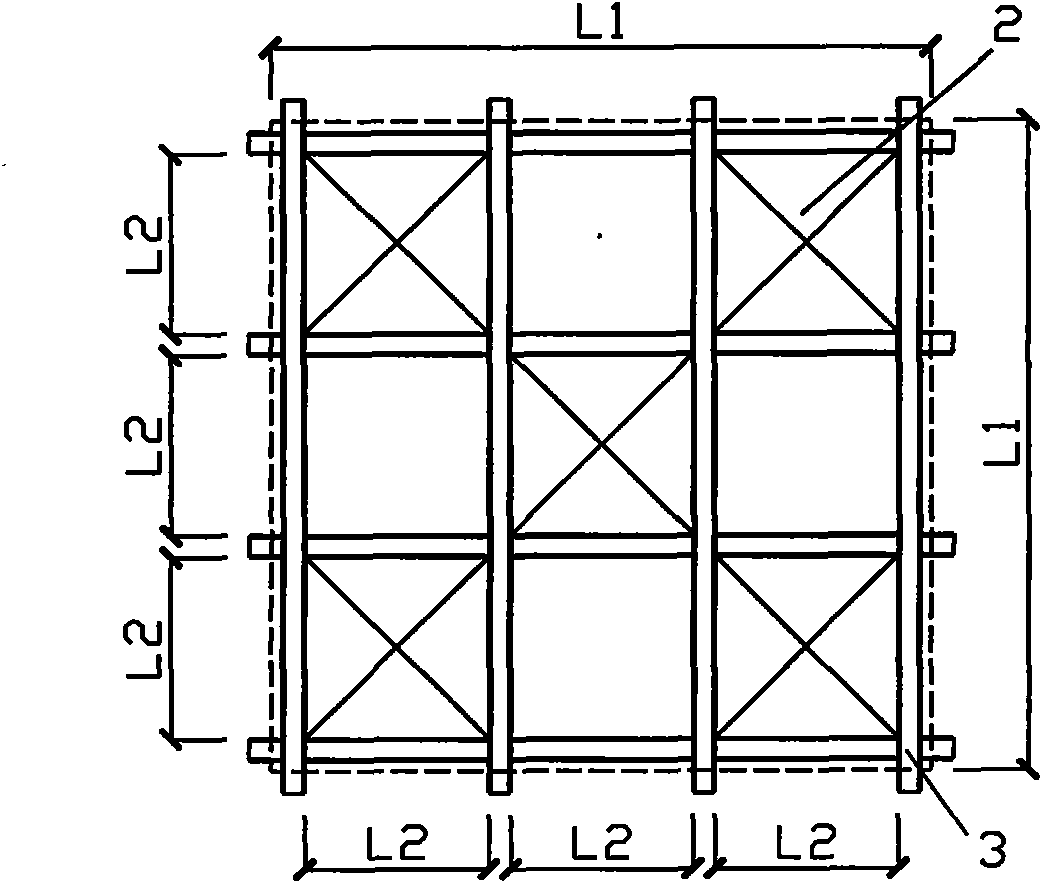

[0037] A light steel damping composite wallboard, such as figure 1 , 11 , 12, 13, the composite wall panel includes a steel frame 3, a damping device 2 and an outer cladding 1.

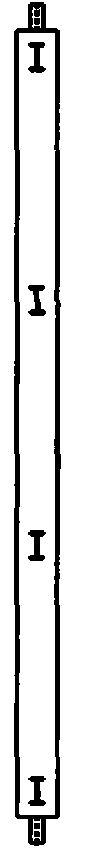

[0038] The shaped steel frame 3 is welded by shaped steel, and the rib beams and rib columns in the frame form several grid cavities.

[0039] The damping device 2 is filled in the grid cavity formed by the rib beam and the rib column, and it is connected with the steel rib beam or the rib column as a whole by welding or bolting.

[0040] The profiled steel frame 3 containing the damper 2 is placed in the template, and the outer cladding 1 is poured with the profiled steel grid as the keel to form a light steel damping type composite wall panel.

[0041] The damping device 2 includes a sprag bending mild steel damper, a bending mild steel damper or a steel plate damper.

[0042] The obli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com