Car roof lamp convenient to assemble

A technology for roof lamps and ceilings, which is applied to the components of lighting devices, motor vehicles, road vehicles, etc. It can solve the problems of large transportation and installation manpower, heavy weight of ceiling lamps, and many manufacturing processes, etc., and achieves light weight and difficult lifting. Ease of use and the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

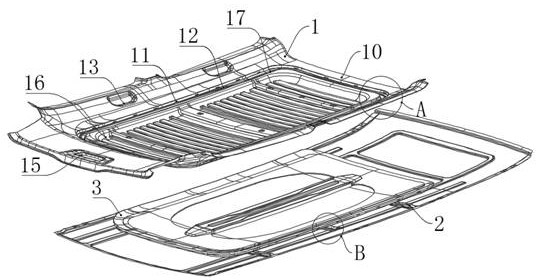

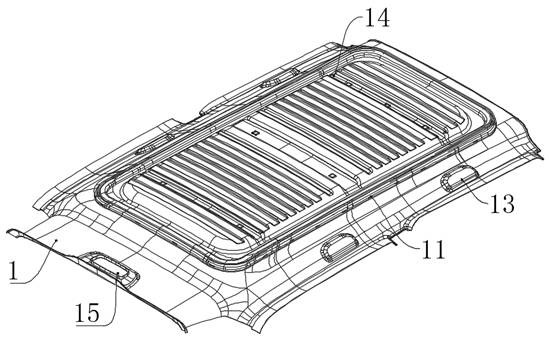

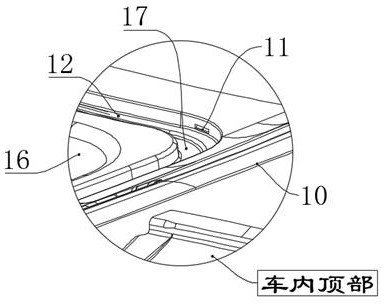

[0027] Such as Figure 1-5 The car dome light shown is easy to assemble, including a roof 1 arranged on the roof of the car, the end surface of the roof 1 facing away from the interior top of the car is snapped with a lighting part 3, and an ambient light embedded on the roof 1 Bar 4, the ambient light bar 4 and the lighting part 3 are located on the same side of the ceiling 1; compared with the traditional car dome light, the number of components is reduced, and the overall volume is reduced due to the absence of a stainless steel frame , Improve transportation efficiency and reduce transportation costs.

[0028] In this embodiment, the lighting element 3 includes a diffused light bead strip, and a light diffusion plate is provided on the side of the diffused light bead strip away from the ceiling 1, and a number of a first elastic insertion protrusion, and the side of the light diffusion plate away from the ceiling 1 is provided with a transparent decorative panel, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap