Chrome plated zinc alloy zipper and electroplating method thereof

A zinc alloy, zipper technology, applied in clothing, fasteners, sliding fastener components, etc., can solve the problems of easy fading or peeling, short service life, poor electrical conductivity, etc., to achieve beautiful colors, good wear resistance, and difficult faded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

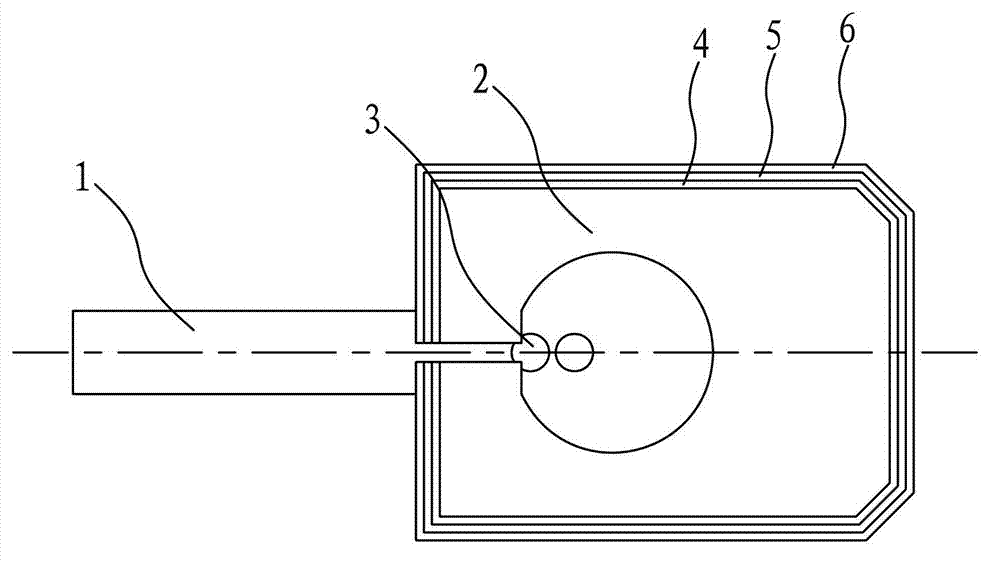

Image

Examples

Embodiment 1

[0026] Embodiment one of the electroplating method for realizing electroplating the above-mentioned chrome-plated zinc alloy slide fastener includes the following process steps:

[0027] (a) Cleaning: use a degreasing powder solution with a mass concentration of 30% or a dewaxing powder solution with a mass concentration of 30% to clean the zinc alloy zipper. The temperature is controlled at 40 degrees, and the oil on the surface of the zinc alloy zipper is removed. Zinc alloy zippers are cleaned.

[0028] (b) Alkaline copper plating: Use cuprous ions with a mass concentration of 4% and a 6% sodium cyanide solution as the electroplating solution, the temperature of the electroplating solution is controlled at 30 degrees, and the zinc alloy zipper is used as the cathode in the electrolytic cell. A layer of alkali copper is plated on the zipper teeth.

[0029] (c) Acid copper plating: using a copper sulfate solution with a mass concentration of 15%, the temperature of the elect...

Embodiment 2

[0042] Embodiment two of the electroplating method for realizing electroplating the above-mentioned chrome-plated zinc alloy slide fastener includes the following process steps:

[0043] (a) Cleaning: Clean the zinc alloy zipper with a degreasing powder solution with a mass concentration of 50% or a dewax powder solution with a mass concentration of 50%. Zinc alloy zippers are cleaned.

[0044] (b) Alkaline copper plating: Use cuprous ion with a mass concentration of 6% and 8% sodium cyanide solution as the electroplating solution, the temperature of the electroplating solution is controlled at 70 degrees, and the zinc alloy zipper is used as the cathode in the electrolytic cell. A layer of alkali copper is plated on the zipper elements.

[0045] (c) Acid copper plating: using a copper sulfate solution with a mass concentration of 25%, the temperature of the electroplating solution is controlled at 40 degrees, and the zinc alloy zipper is used as the cathode in the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com