Mineral cable production and processing equipment

A processing equipment and cable technology, which is applied in the field of mineral cable production and processing equipment, can solve the problems of low debris collection effect, waste of manpower consumption, and single function, and achieve the effects of reducing manpower consumption, reducing cleaning difficulty, and improving collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

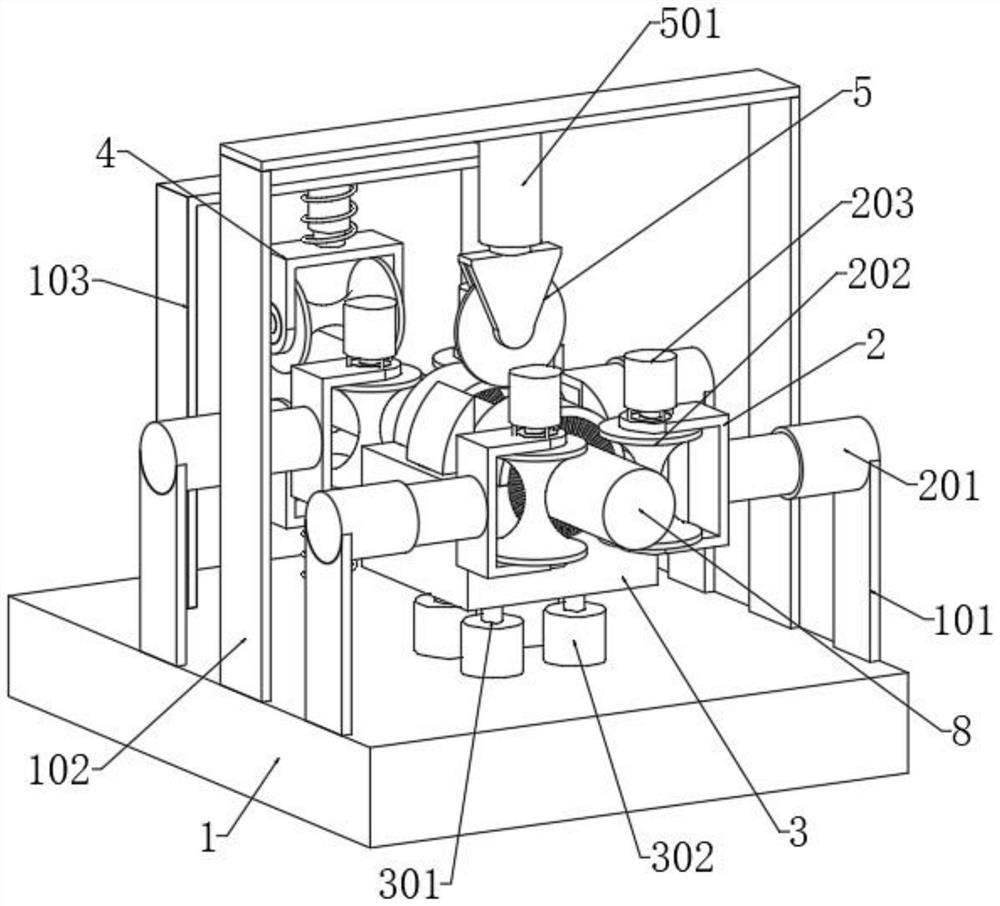

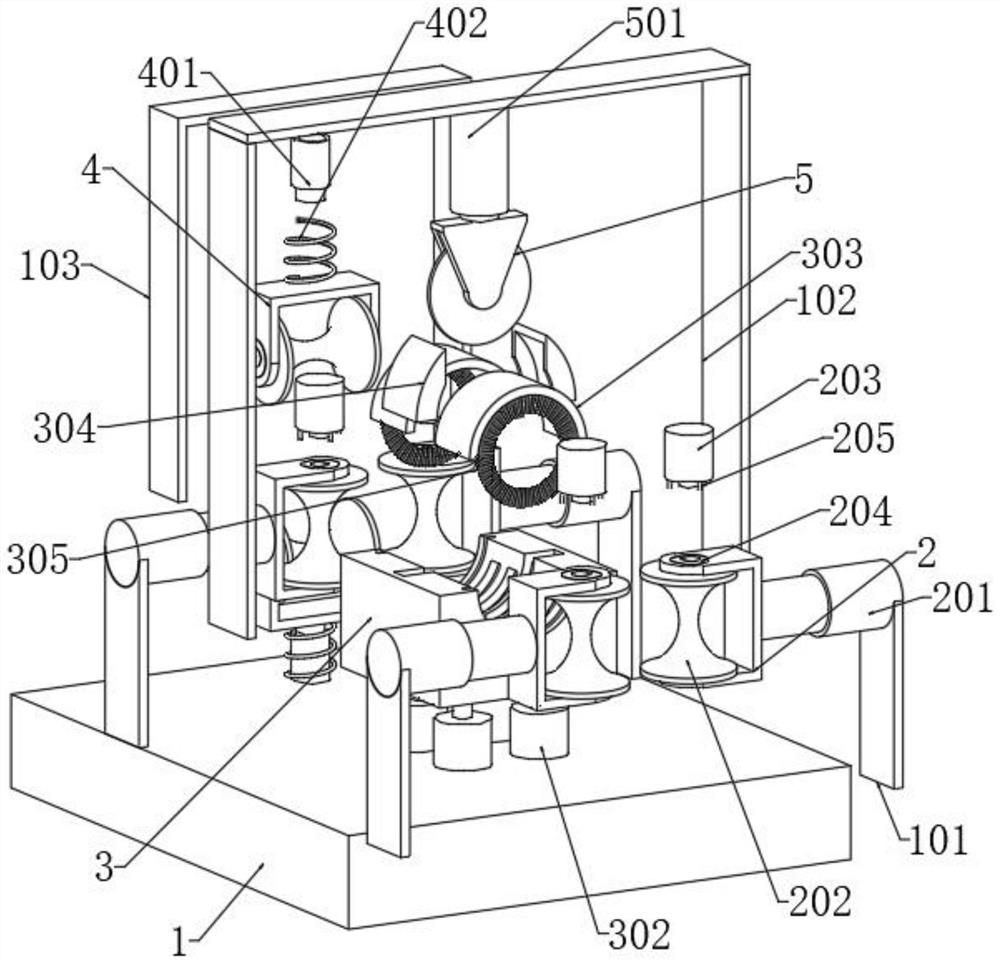

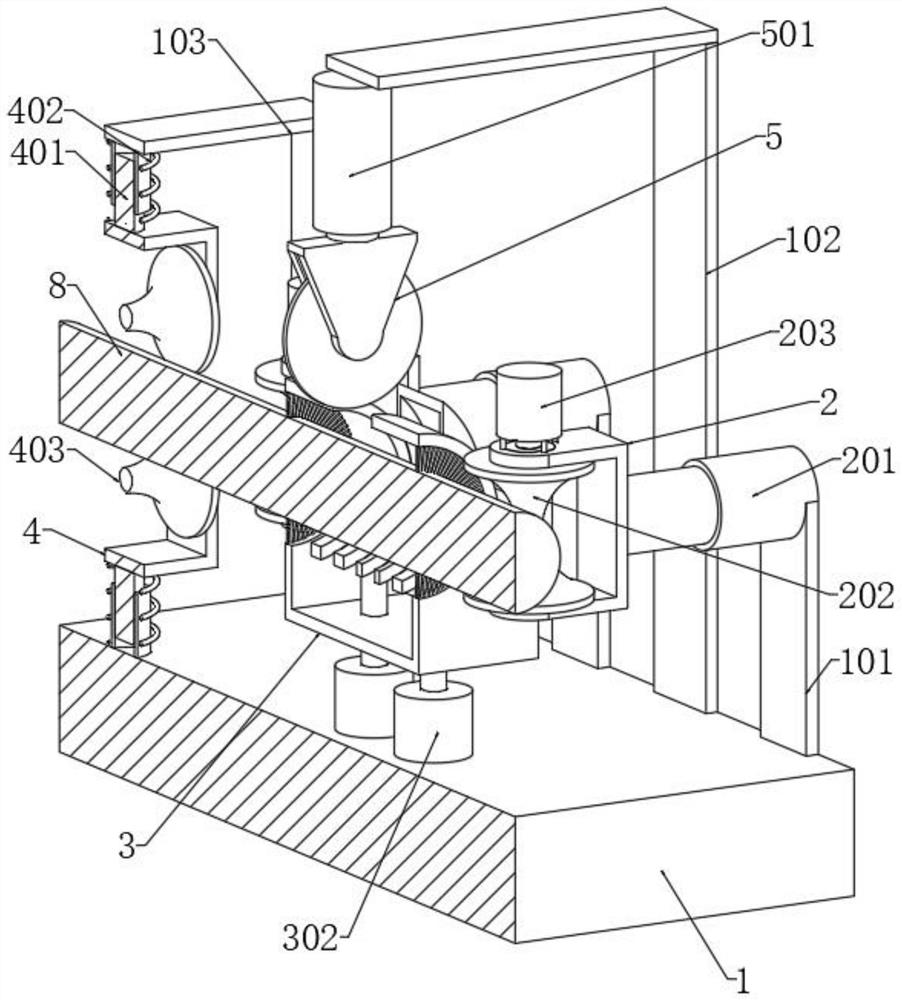

[0025] Such as Figure 1-6 As shown, a mineral cable production and processing equipment includes a base 1, a collection box 3 is fixedly installed on the top of the base 1, a No. No. 2 runner 202, No. 2 clamp frame 4 is movably installed on the top of base 1 near the rear, No. 2 runner 403 is movably embedded in No. 2 clamp frame 4, cutting device 5 is movably installed above collection box 3, and collection box 3 A sealing plate 6 is movably embedded on the surface of one side, a vibrating motor 7 is fixedly installed on the lower surface of the collection box 3, and a cable 8 is movably interspersed inside the collection box 3;

[0026]A support plate 101 is fixedly installed on the upper surface of the base 1, a No. 1 beam 102 is fixedly installed on the upper surface of the base 1, a No. 2 beam 103 is fixedly installed on the upper surface of the base 1 close to the rear surface, and a hydraulic rod 501 is fixedly installed on the upper surface of the cutting device 5. T...

Embodiment 2

[0028] It should be noted that the present invention is a mineral cable production and processing equipment. When in use, the cable 8 passes between the two second runners 403, and under the elastic force of the strong spring 402, the second runner 403 and the Cable 8 fits, telescopic rod 401 increases the stability of powerful spring 402, then controls motor 203 to rotate, makes No. Make the cable 8 move, and the cable 8 passes between the other two No. 1 runners 202 after passing through the collection box 3, so that the cable 8 is straightened inside the collection box 3, and the stability during cutting is increased. When cutting, the motor is controlled 203 stops running, and the No. 1 runner 202 fixes the cable 8, and then controls the cutting device 5 to move down, and the cable 8 is cut, and the vibration motor 7 is started at the same time, and the baffle plate 304 blocks the debris generated by cutting to the inside of the collection box 3, Simultaneously, the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com