Angle grinder capable of sensing infrared rays

An angle grinder, infrared technology, used in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problems of heat source, light source interference, infrared radiation being easily blocked, and failure to trigger recovery in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

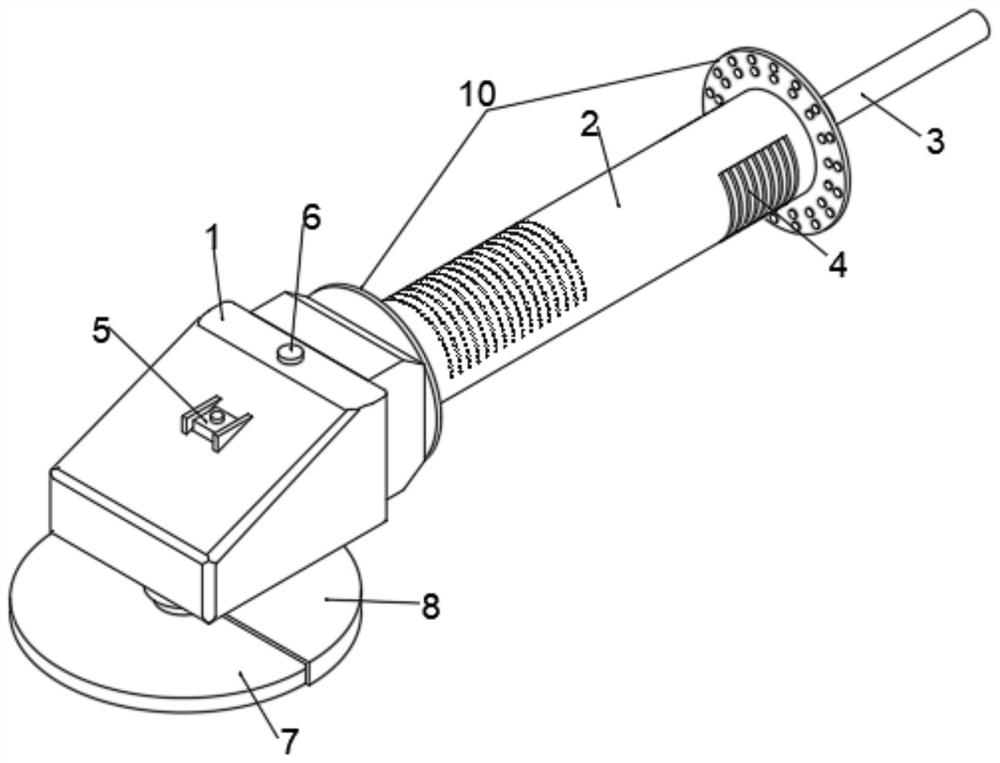

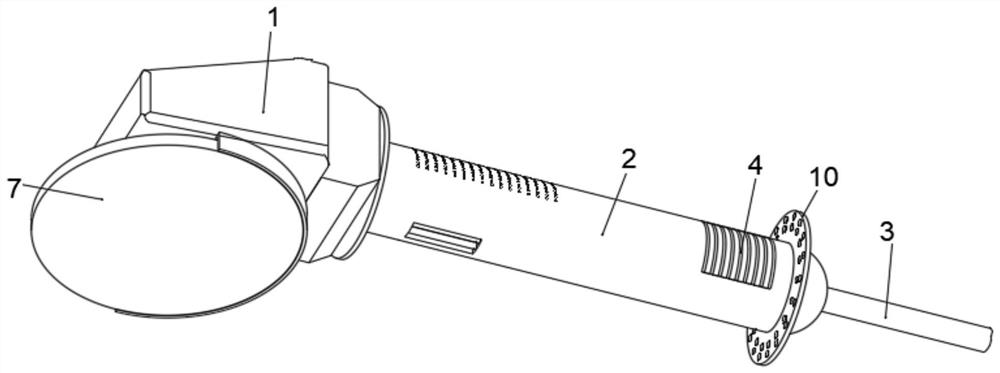

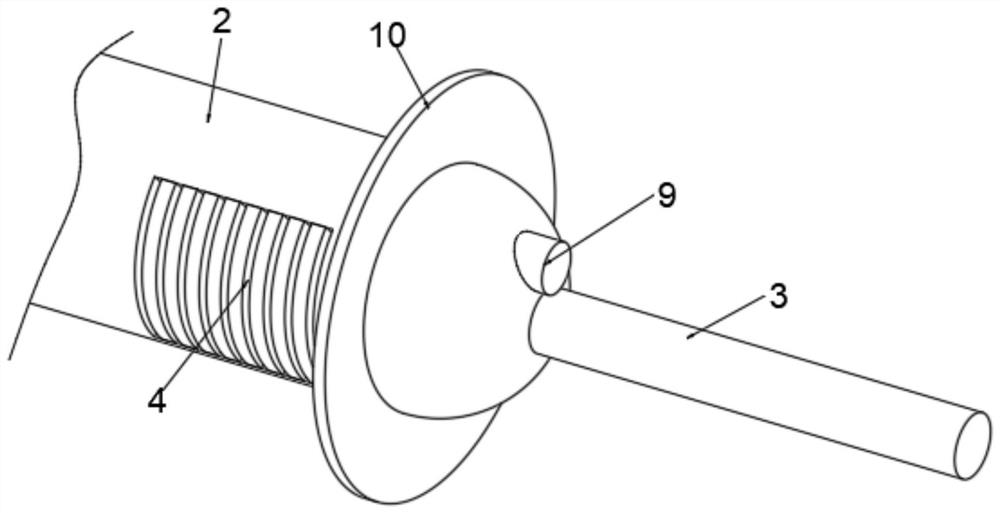

[0027] see Figure 1-Figure 4 , the present invention provides a technical solution: an infrared induction angle grinder, including a metal machine head 1 and a handle 2, the metal machine head 1 is respectively provided with a spindle lock button 5 and an emergency stop button 6, the metal machine A grinding head 7 is movable on the head 1, a filter sheath 8 is fixedly installed on the connecting shaft of the grinding head 7, a power cord 3 is connected to one end of the handle 2, a motor is fixedly installed inside the handle 2, and a motor is fixed inside the handle 2. A motor cooling frame 4 is fixedly installed through the inner wall, a power switch 9 is arranged on the tail end side of the handle 2, and an induction circuit is arranged in the handle 2, and the induction circuit includes an infrared emitting tube 10, an infrared receiving tube and a relay.

[0028] In this embodiment, the surface of the handle 2 is provided with anti-skid lines.

[0029] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com