Control method for aero-engine bladed disc repair and three-dimensional reconstruction and application thereof

An aero-engine, three-dimensional reconstruction technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as pitting, fatigue, cracks, etc., to avoid joint restrictions, high repair and reconstruction accuracy, and good control robustness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

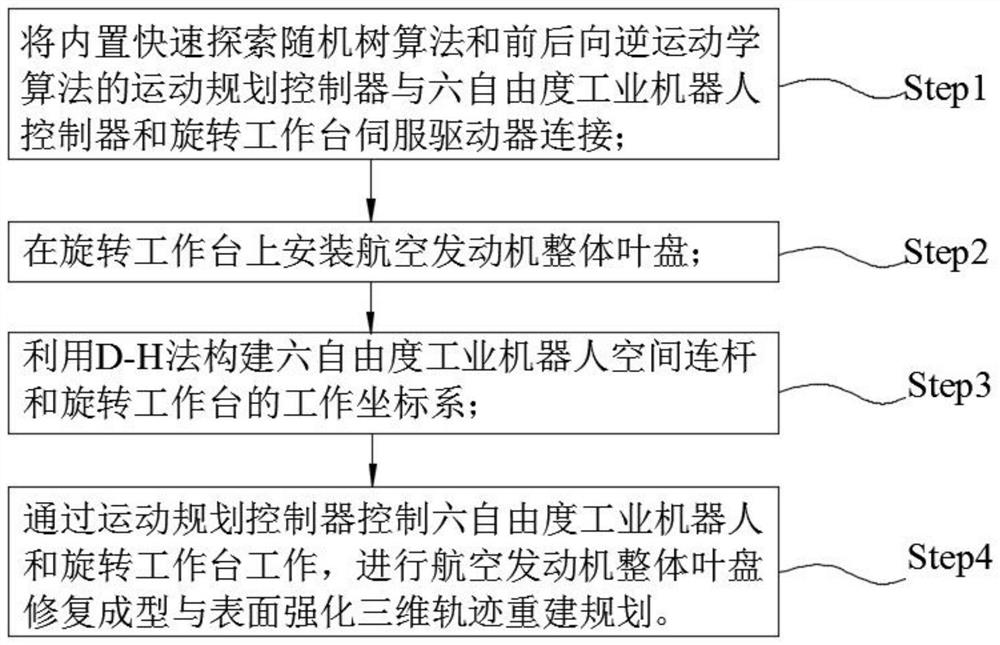

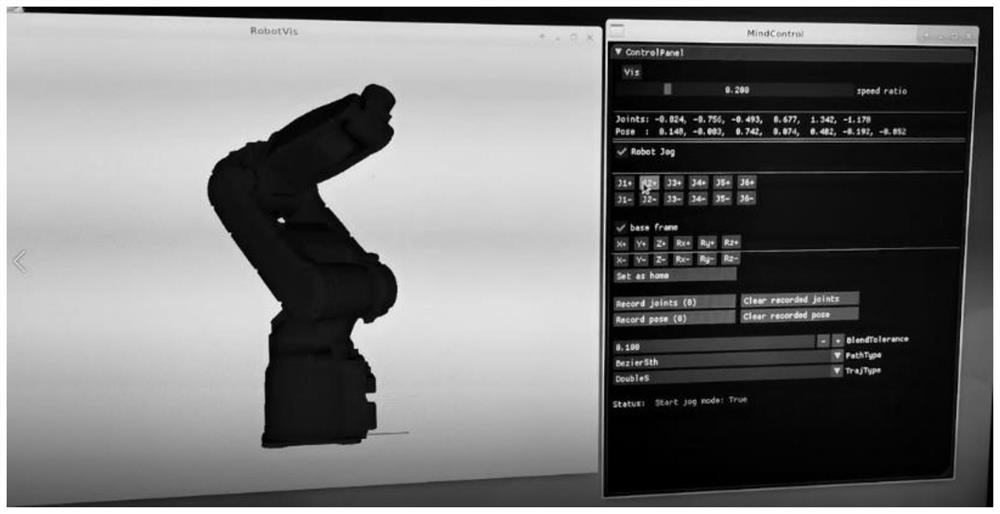

[0095] Embodiment 1: Using the motion planning controller described in the present invention to implement the robot trajectory planning method to carry out the specific process of blisk repair and forming includes

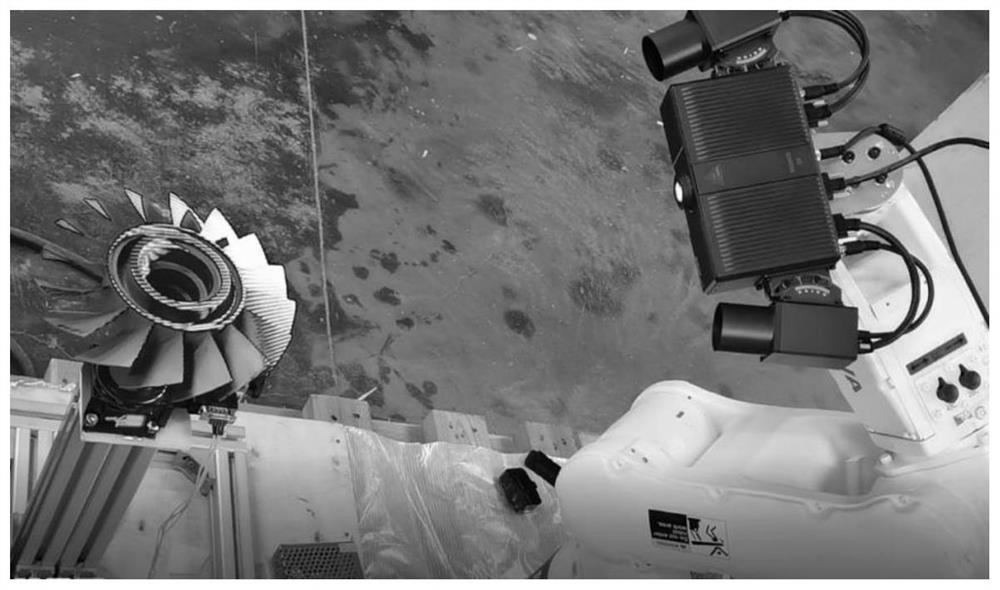

[0096] Step S1: Install the area array structured light camera on the end of the industrial robot arm, and clamp the blade to be tested on the rotary table;

[0097] Step S2: Define the end coordinate system {O 0}, base coordinate system {O 1}, rotating table coordinate system {O 2};

[0098] Step S3: Establish the kinematic equations of the industrial robot and the rotary table through the D-H (Denavit-Hartenberg) method built in the motion planning controller;

[0099] Step S4: Set the single rotation angle and dwell time of the rotary table according to the complexity of the fan blade to be tested;

[0100] Step S501: designate two measurement points as the target position of the end effector of the industrial robot;

[0101] Step S502: Use the cylinder wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap