Double-station rotary screen printing machine

A printing machine and double-station technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of low cleaning efficiency, inconvenient use, waste of manpower and material resources, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

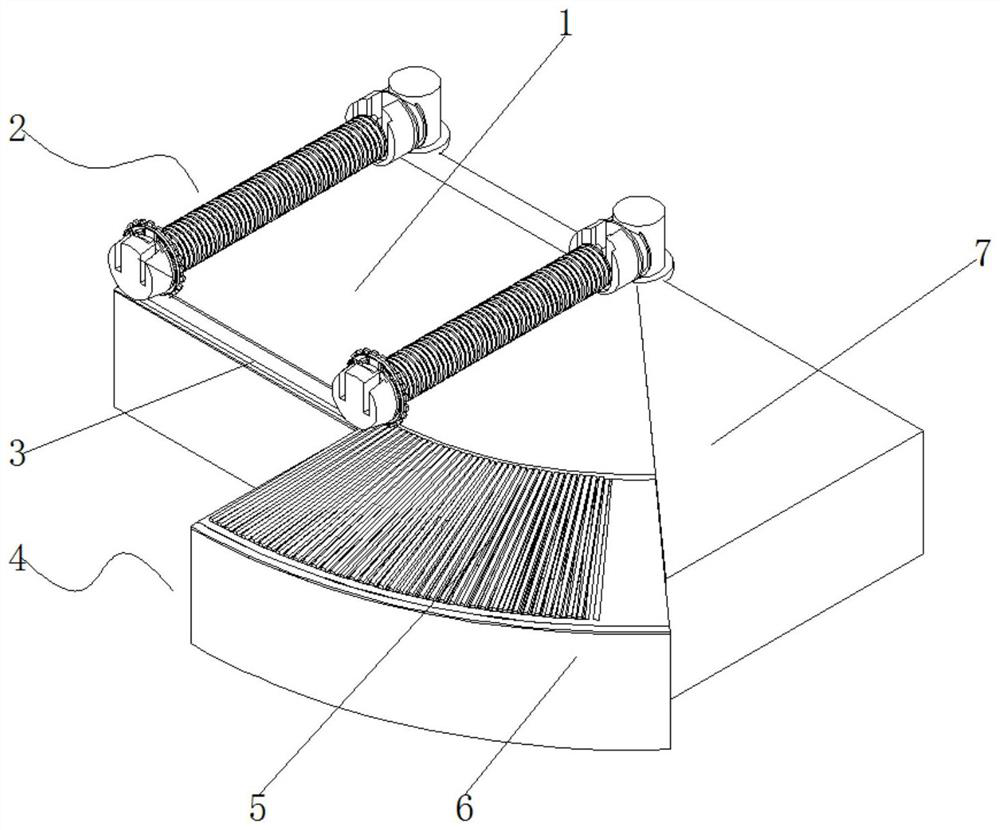

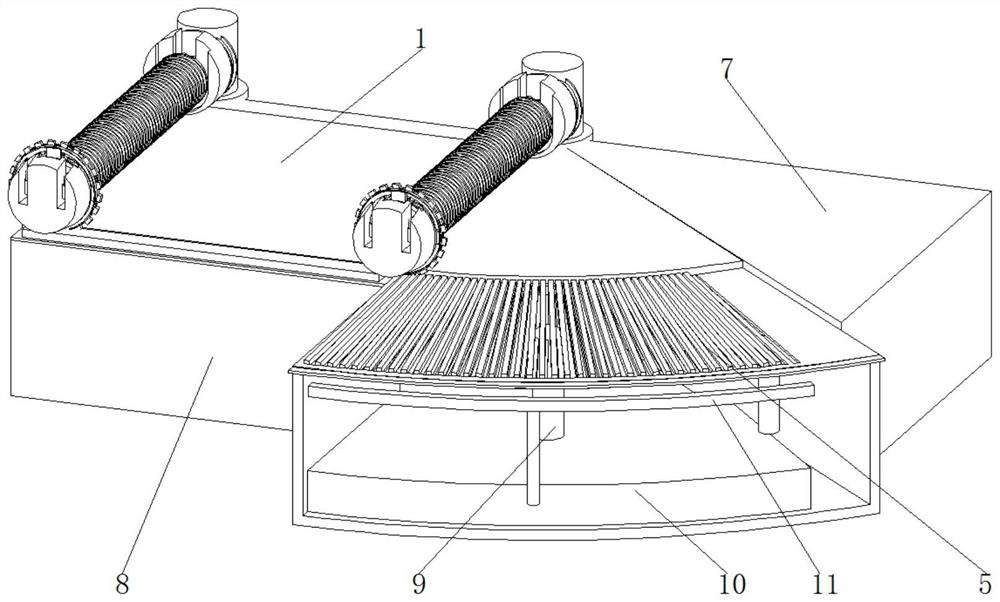

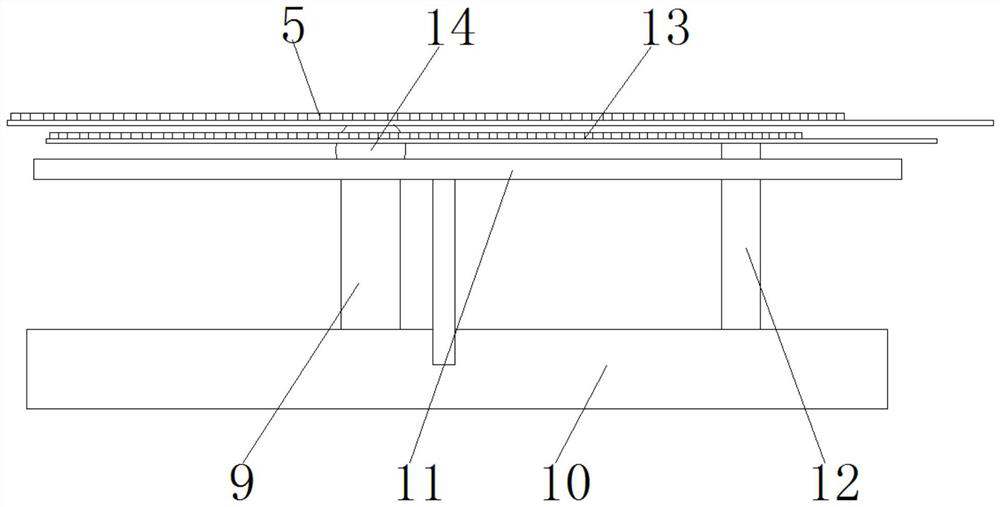

[0027] The embodiment of the present invention provides a double-station rotary screen printing machine, such as Figure 1-8 As shown, it includes a workbench 8, two main slideways 3, a moving platform 7, a cleaning assembly 4 and a plurality of printing cylinder assemblies 2. Two main slides 3 are arranged symmetrically on both sides of the workbench 8 , and a plurality of printing cylinder assemblies 2 are slidably fitted on the main slides 3 . The mobile platform 7 is connected to the workbench 8 through the cleaning assembly 4, and the cloth 1 is arranged on the workbench 8, the mobile platform 7 and part of the box body 6. The printing cylinder assembly 2 includes a drive assembly 19 , a cylinder 20 and a split assembly 15 . The driving assembly 19 is connected with the splitting assembly 15 through the cylinder 20 . Both the split assembly 15 and the drive assembly 19 are slidably fitted on the main slideway 3 .

[0028] The printing cylinder assembly 2 also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com