Automatic hot stamping machine

A hot stamping machine and automatic technology, which is applied in the field of clothing hot stamping, can solve the problems of large hot stamping loss, etc., and achieve good practicability and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

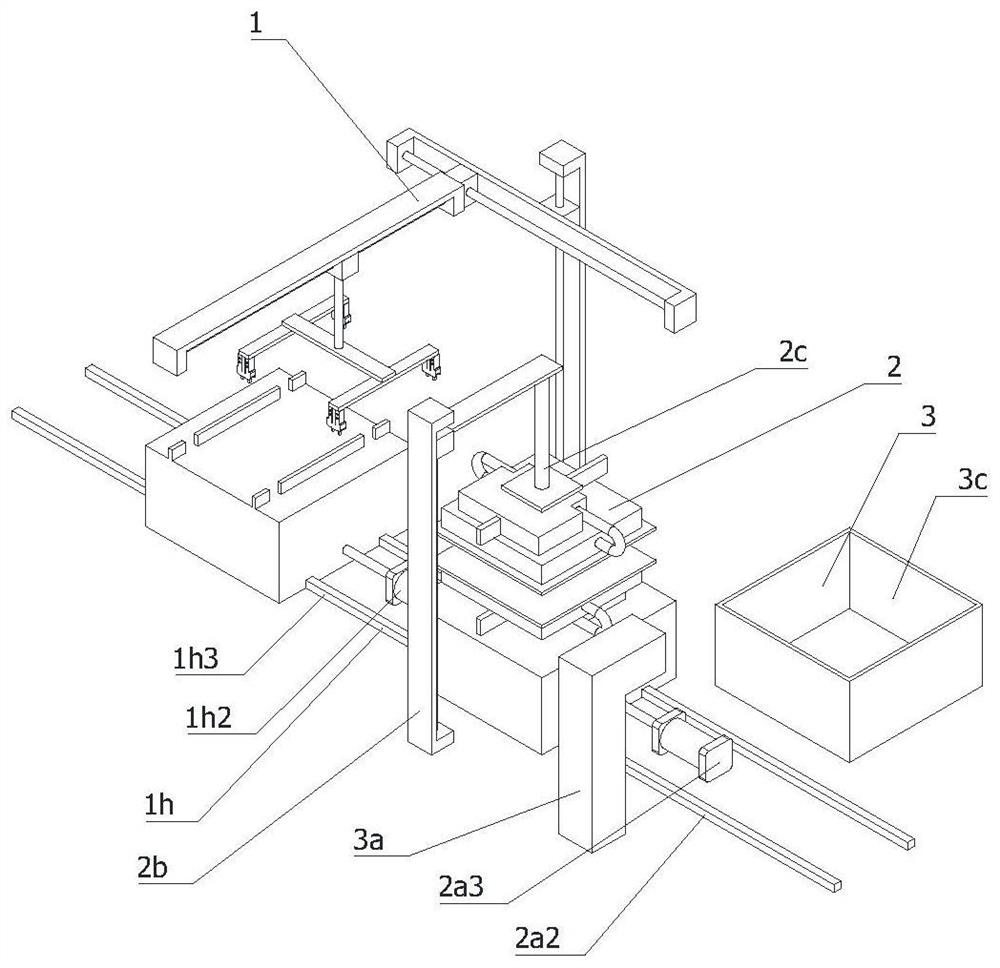

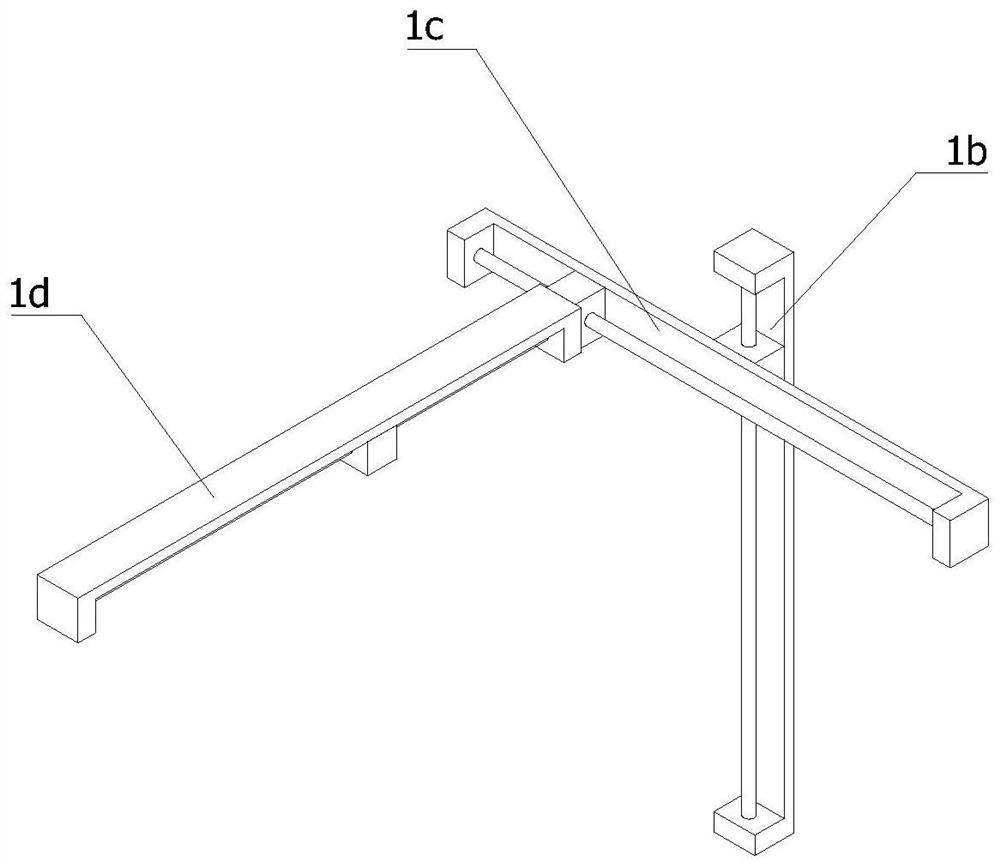

[0062] Such as figure 1 , 5 , shown in 6 and 7, an automatic hot stamping machine, including a frame and a hot stamping device 2 arranged on the frame, the hot stamping device 2 includes,

[0063] Base 2a;

[0064] The fourth linear driver 2b, the fourth linear driver 2b is fixedly installed on the frame, and the driving direction of the fourth linear driver 2b is vertically arranged;

[0065] The upper bracket 2c, the upper bracket 2c is arranged on the driving end of the fourth linear driver 2b, and the upper bracket 2c performs vertical reciprocating motion under the action of the fourth linear driver 2b;

[0066] The semiconductor heating plate 2d has two or two semiconductor heating plates 2d respect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap