A kind of preparation method of acetate compound and adopted catalyst

An esterification catalyst and compound technology, applied in the preparation of organic compounds, organic compounds/hydrides/coordination complex catalysts, preparation of carboxylic acid esters, etc. Production costs and other issues, to achieve high acid and alkali resistance, solve environmental pollution, reduce comprehensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] At 45 °C, 20 g of MCM-248 molecular sieve and 200 g of polyvinylpyrrolidone (PVP) (CAS: 9003-39-8, K30) were dispersed in 200 mL of deionized water, and the stirring was started to make it evenly dispersed. After 8 hours, filter The solid was taken out, and placed in a vacuum drying oven at 80° C. and dried to obtain a modified carrier, which was recorded as MCM-248-PVP. At 25 °C, 4.83 g of FeCl 3 ·6H 2 O was dissolved in 10 mL of deionized water, then the modified carrier MCM-248-PVP was added, and stirring was started. The temperature was raised to 45°C, kept for 6 hours, filtered, and the obtained solid was dried in a vacuum drying oven at 80°C to obtain a catalyst of 5.0wt.% FeCl 3 / MCM-248-PVP.

[0070] Loading amount = (metal relative atomic mass / metal salt relative molecular weight * metal salt mass) / carrier mass * 100%

Embodiment 2~54

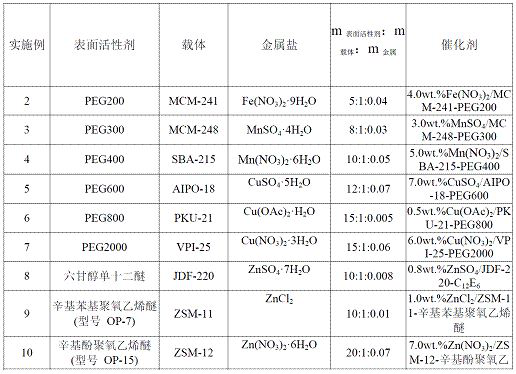

[0072] By changing the types and proportions of surfactants, carriers and metal salts, following the method of Example 1, the following catalysts were obtained respectively (as shown in Table 1).

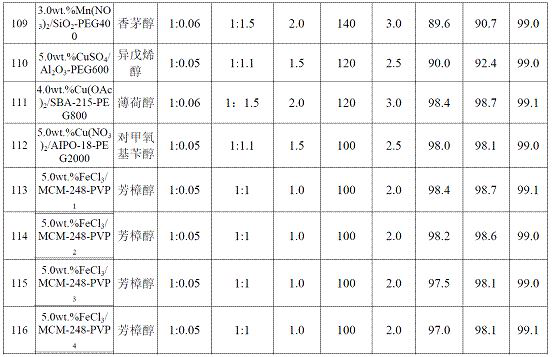

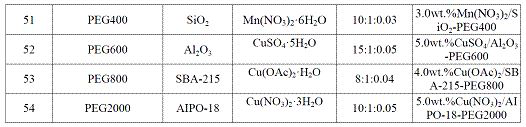

[0073] Table 1 Catalyst and preparation parameters

[0074]

[0075]

[0076]

[0077]

[0078] acac stands for acetylacetone; OAc stands for acetate.

Embodiment 55

[0080] At 20 °C, 20 g of MCM-248 molecular sieve and 200 g of polyvinylpyrrolidone (PVP) (CAS: 9003-39-8, K30) were dispersed in 200 mL of deionized water. The solid was taken out, and placed in a vacuum drying oven at 80° C. and dried to obtain a modified carrier, which was recorded as MCM-248-PVP. At 25 °C, 4.83 g of FeCl 3 ·6H 2 O was dissolved in 10 mL of deionized water, then the modified carrier MCM-248-PVP was added, and stirring was started. The temperature was raised to 45°C, kept for 6 hours, filtered, and the obtained solid was dried in a vacuum drying oven at 80°C to obtain a catalyst of 5.0wt.% FeCl 3 / MCM-248-PVP 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com