Photographic fixing apparatus, temperature-controlling method and image forming apparatus

A temperature control method and a technology for fixing temperature, which are applied to electric heating devices, electric recording technology using charge patterns, and equipment for electric recording technology using charge patterns, etc., which can solve problems such as lifespan reduction, deterioration, and poor thermal response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

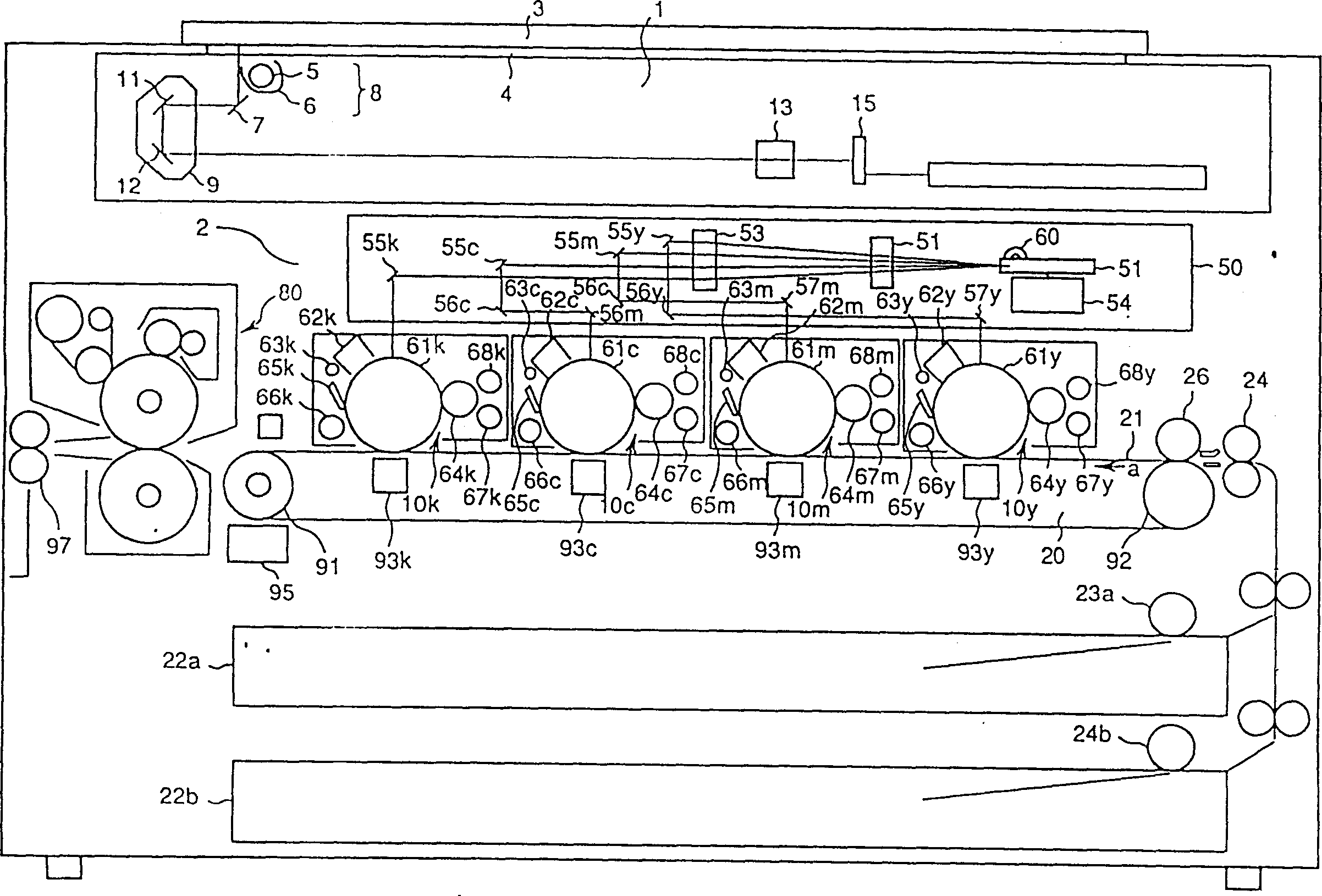

[0022] figure 1 It is a schematic configuration diagram of a full-color copier related to the image forming apparatus of the present invention. A full-color copier is composed of a scanner section 1 as a reading device and a printer section 2 as an image forming device.

[0023] The scanning unit 1 for reading the image of the document has a document table cover 3 on its upper part, and has a document table made of transparent glass for placing the document D opposite to the closed document table cover 3 4. Below the original table 4, an exposure lamp 5 for illuminating the original D placed on the original table 4, a reflector 6 for converging the light of the exposure lamp 5 on the original D, and light from the original D are provided. The reflected light turns to the left in the figure to the first reflector 7 and the like. In addition, these exposure lamps 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com