Phase change temperature control device for electronic heating components and manufacturing method thereof

A technology for heating components and temperature control devices, which is applied in cooling/ventilation/heating renovation, heat storage equipment, heat exchanger types, etc. line, avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

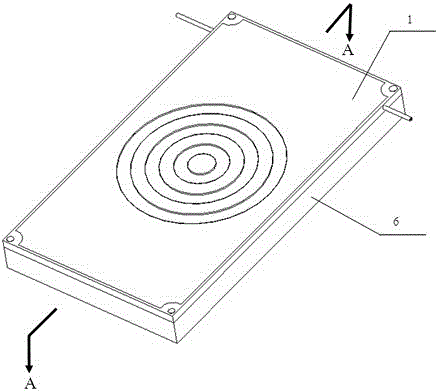

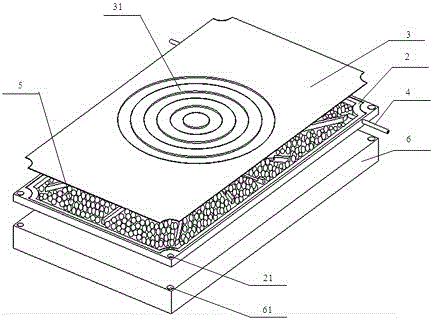

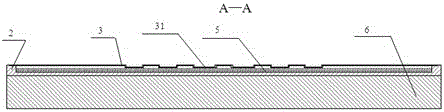

[0034] The following combination Figure 1 to Figure 5 , a preferred embodiment of the present invention is described in detail.

[0035] like Figure 1 ~ Figure 3 As shown, the phase change temperature control device 1 of the electronic heating component provided by the present invention controls the temperature of the electronic heating component 6, and specifically includes: a housing 2, which has an inner cavity, and the housing 2 The outer bottom surface is arranged in close contact with the electronic heating component 6; the cover plate 3 is welded and arranged on the top of the housing 2, so that the inner cavity of the housing 2 becomes a closed space; the auxiliary vacuum tube 4 , which are respectively welded on both sides of the housing 2 and respectively pass through the side walls of the housing 2 ;

[0036]Each corner of the housing 2 is provided with a first screw hole 21, and each corner of the electronic heating component 6 is respectively provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com