High-performance pure electric motor sweeper

A pure electric, sweeper technology, used in cleaning methods, road cleaning, construction, etc., can solve the problems of low cleaning efficiency, increase labor intensity of workers, inconvenient garbage collection operations, etc., and achieve the effect of convenient operation and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

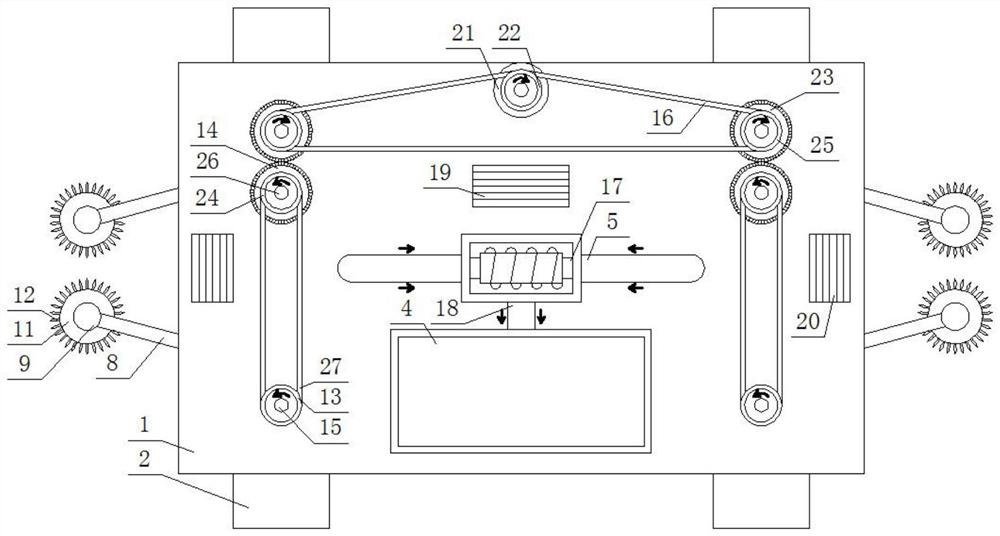

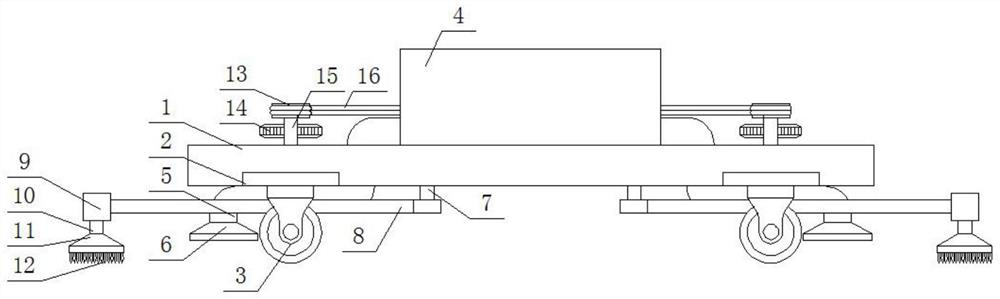

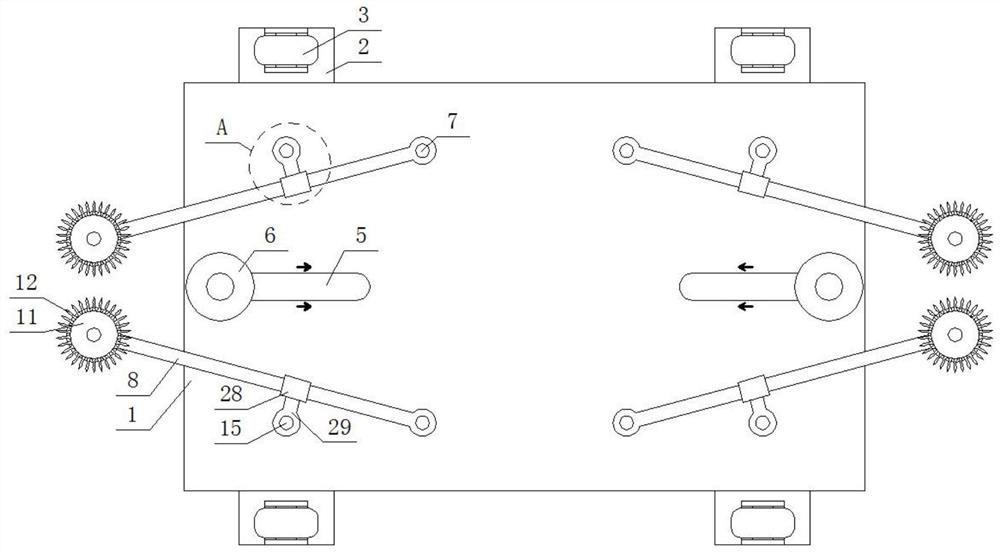

[0027] Such as Figure 1-4 As shown, a high-performance pure electric sweeper includes a base plate 1, a pair of symmetrical connecting plates 2 are fixed on the front and rear sides of the base plate 1, and a roller bracket is installed on the bottom surface of each connecting plate 2, and each roller Rollers 3 are all installed on the support. The setting of the roller 3 increases the convenience of moving the whole device. The top surface of the base plate 1 is evenly provided with four rotating shafts 15, each rotating shaft 15 runs through the bottom surface of the base plate 1 and is connected to the base plate 1 in rotation, and the bottom surface of each rotating shaft 15 is fixedly equipped with a swing guide rod 29, each A cleaning assembly is arranged between the swing guide rod 29 and the base plate 1; the cleaning assembly includes a fixed shaft 7, which is arranged on the bottom surface of the base plate 1 and fixedly connected with the base plate 1, and the bot...

Embodiment 2

[0031] Such as Figure 1-4 Shown, under the situation that other parts are all identical with embodiment 1, the difference between this embodiment and embodiment 1 is:

[0032] The dust suction assembly includes a dust suction pump 17, which is installed on the top surface of the base plate 1. The model of the dust suction pump 17 is XWB-530, and the dust suction pump 17 is electrically connected to the first battery board 19 through a power line. The dust inlet ends of the left and right ends of the dust suction pump 17 are connected and fixed with a dust suction pipe 5, and the bottom of each dust suction pipe 5 runs through the bottom plate 1 and is fixedly connected with the bottom plate 1. The bottom ends are all communicated with and fixedly provided with a dust collection tray 6, the end of the dust discharge end of the dust collection pump 17 is connected with and fixedly provided with a dust discharge pipe 18, and the front of the dust collection pump 17 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com