Ditching device for underwater cable laying and underwater cable laying method

A technology for cable laying and trenching machines, which is applied to earth movers/excavators, construction, etc., and can solve problems such as coulter damage, mechanical parts deformation and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

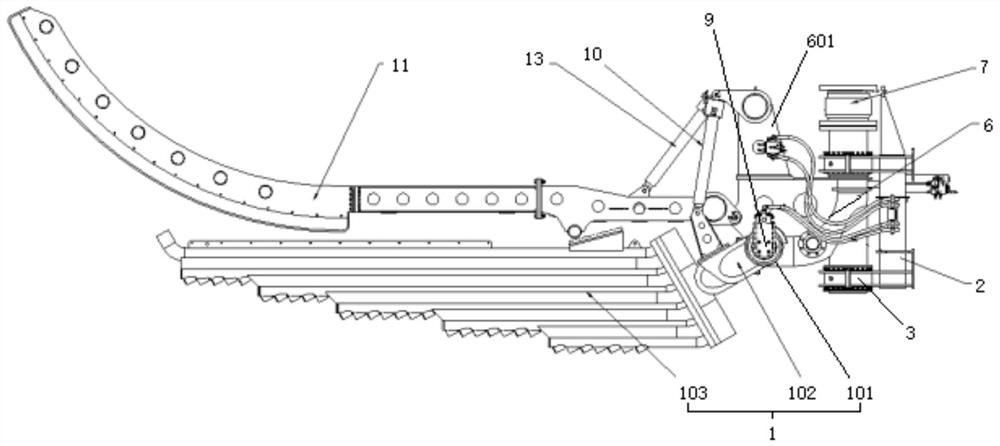

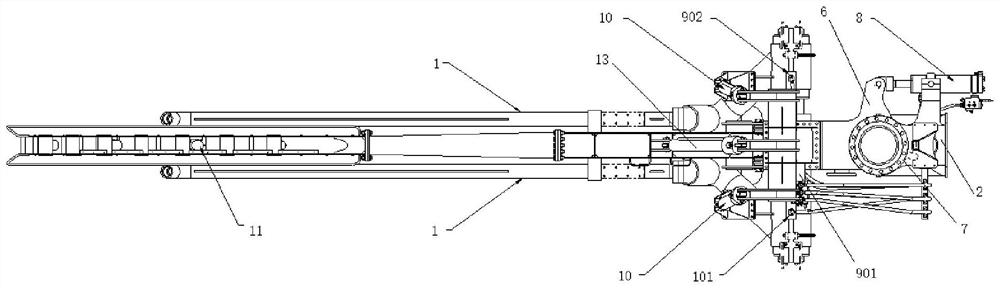

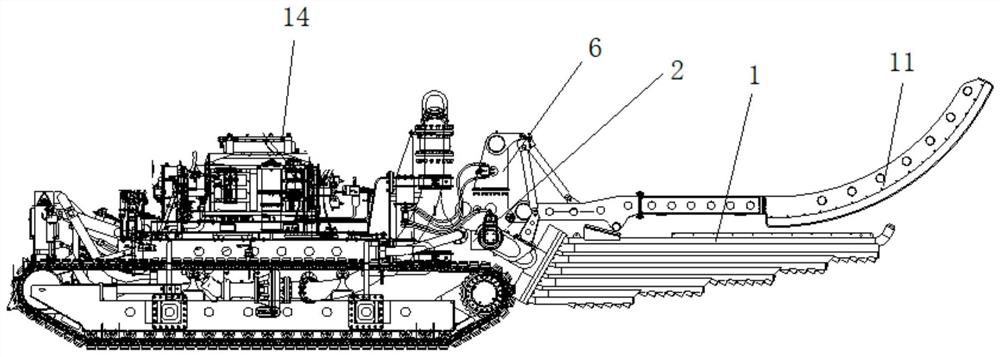

[0037] Such as Figure 1-18 As shown, the present invention provides a trenching device for underwater cable laying, including a trencher 14 and a coulter assembly arranged at the tail of the trencher 14, and the coulter assembly includes a base connected to the trencher 14 2. The support 6 arranged on the base 2 and the spray coulter 1 arranged on the support 6 through the drive assembly, the base 2 is provided with a rotating seat 3, and the support 6 is rotatably arranged on the rotating seat 3, and includes A driving member 8 for driving the bracket 6 to rotate along the rotating base 3 , and a locking structure for controlling the free rotation or locking of the bracket 6 and the base 2 .

[0038] The bracket 6 of the present invention is connected to the trenching machine 14 through the base 2, and the bracket 6 can freely rotate along the base 2 or lock and adjust the angle through the locking structure, so as to adapt to different situations. When the driver 8 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com