Pipe jacking machine for water conservancy project

A technology of water conservancy projects and pipe jacking machines, which is applied to mining equipment, tunnels, earthwork drilling and mining, etc. It can solve problems such as excessive wear of the cutter head, head stuck in the hole, delay in construction period, etc., and achieve the goal of increasing the jacking distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

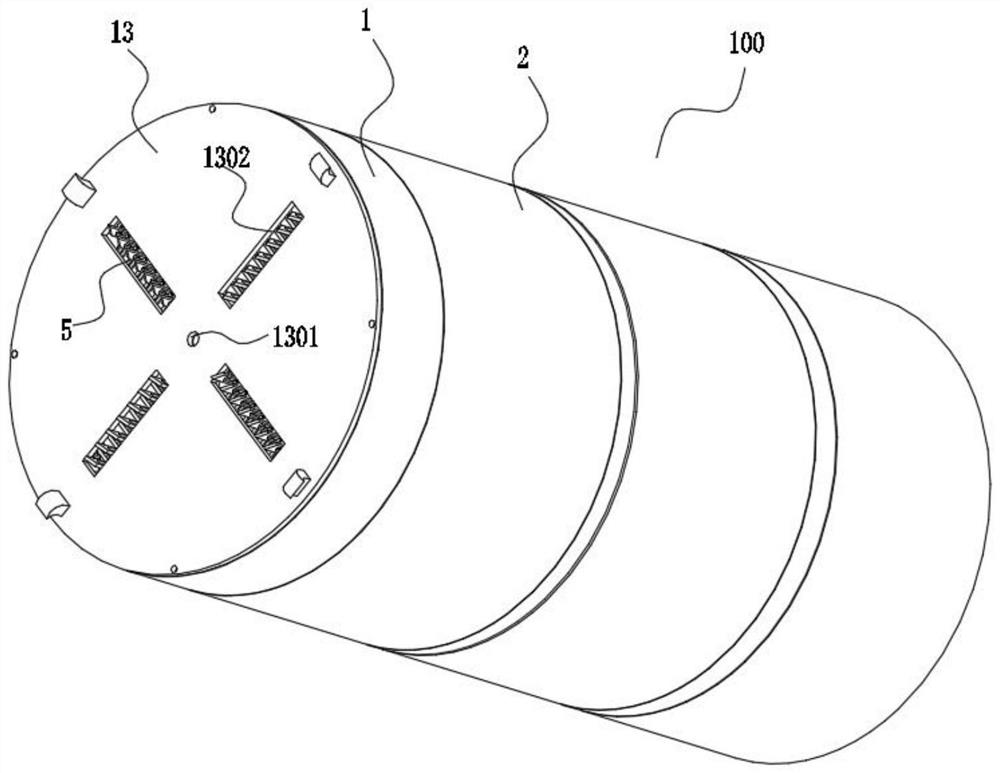

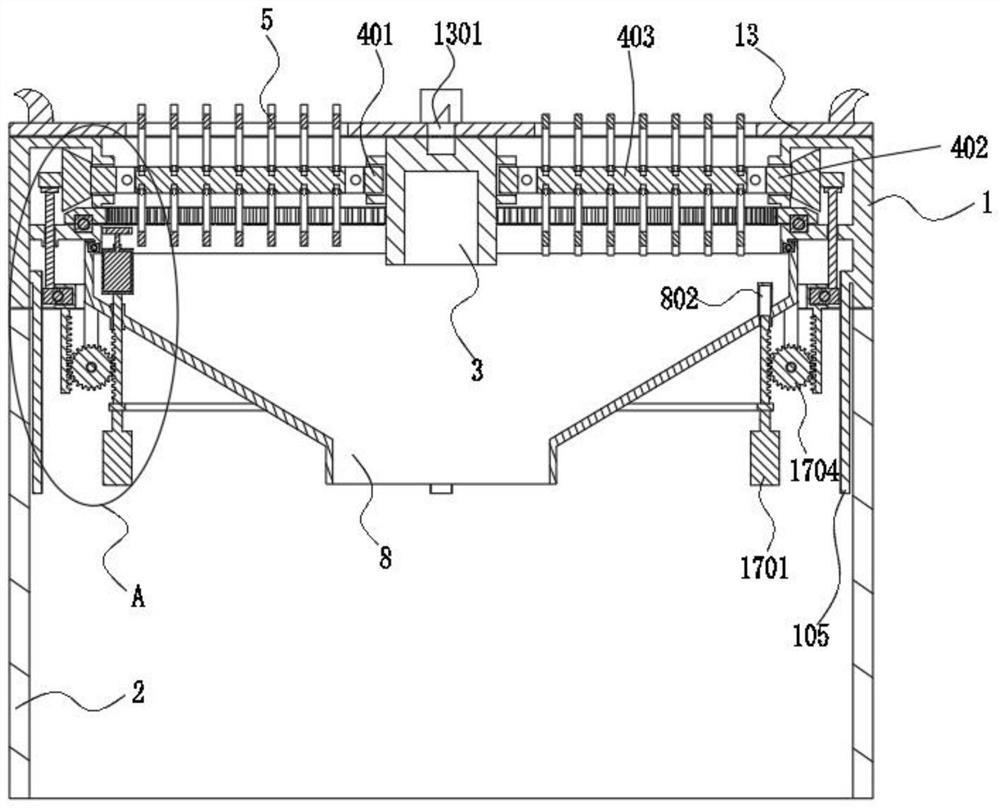

[0035] A kind of hydraulic engineering pipe jacking machine of the present embodiment, refer to figure 1 , 2 and 5: pipe jacking machine 100

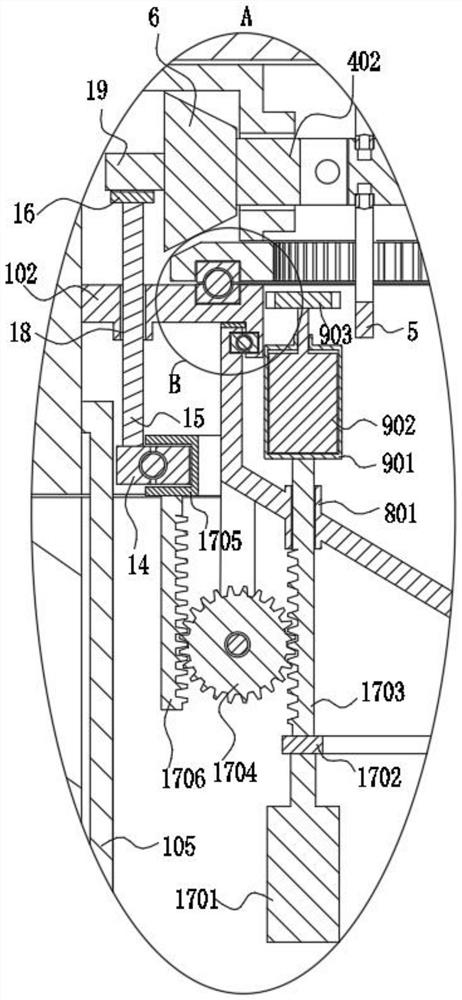

[0036] It includes a cutting cutterhead 1 and a driving part housing 2 coaxial with the cutting cutterhead 1, and a driving part that drives the cutting cutterhead 1 to rotate is arranged in the driving part housing 2 (the principle of driving the cutting cutterhead 1 by the driving part has been described in the background It is described in detail in the patent of the technology, and will not be described here), the cutting disc 1 is fixedly installed with the coaxial shaft part 3, and there are at least two equiangular rotation connections between the cutting disc 1 and the shaft part 3. A group of shaft rods 4, at least two groups of blade groups are fixedly installed on the shaft rod 4 at equal distances, each group of blade groups includes at least two axisymmetric blades 5, and the end of the shaft rod 4 away from the shaft cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com