Hot oil pump with oil-gas multi-stage separation mechanism and method

A multi-stage separation and thermal oil pump technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as oil cracking, mechanical seal damage, thermal oil pump mechanical seal damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

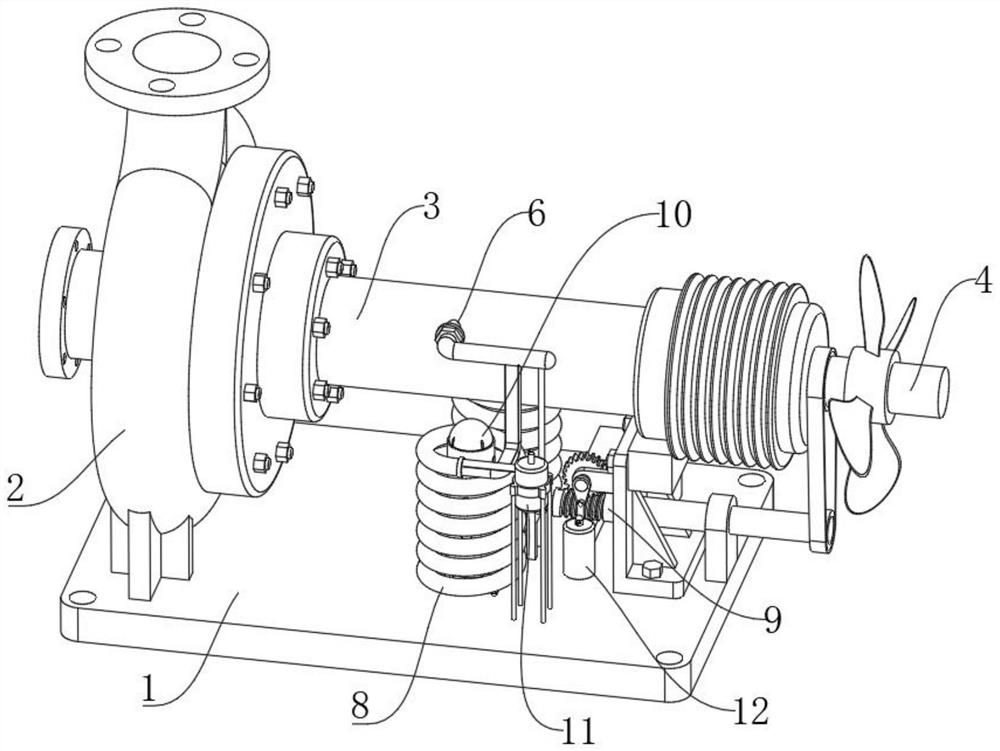

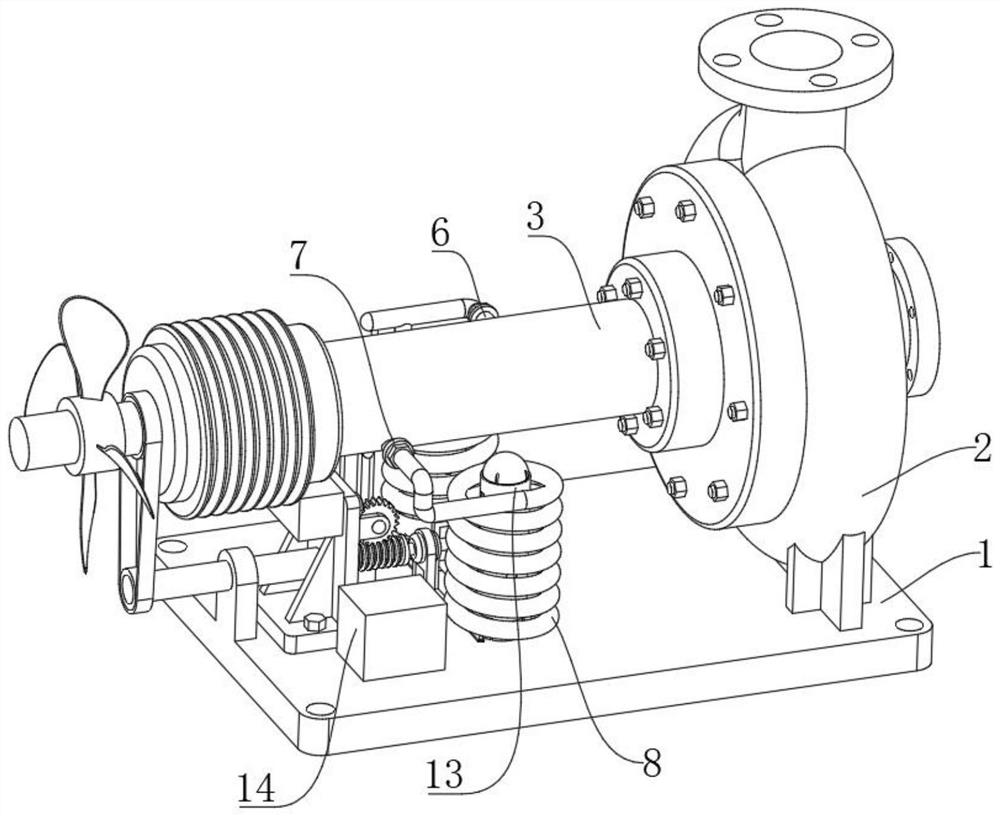

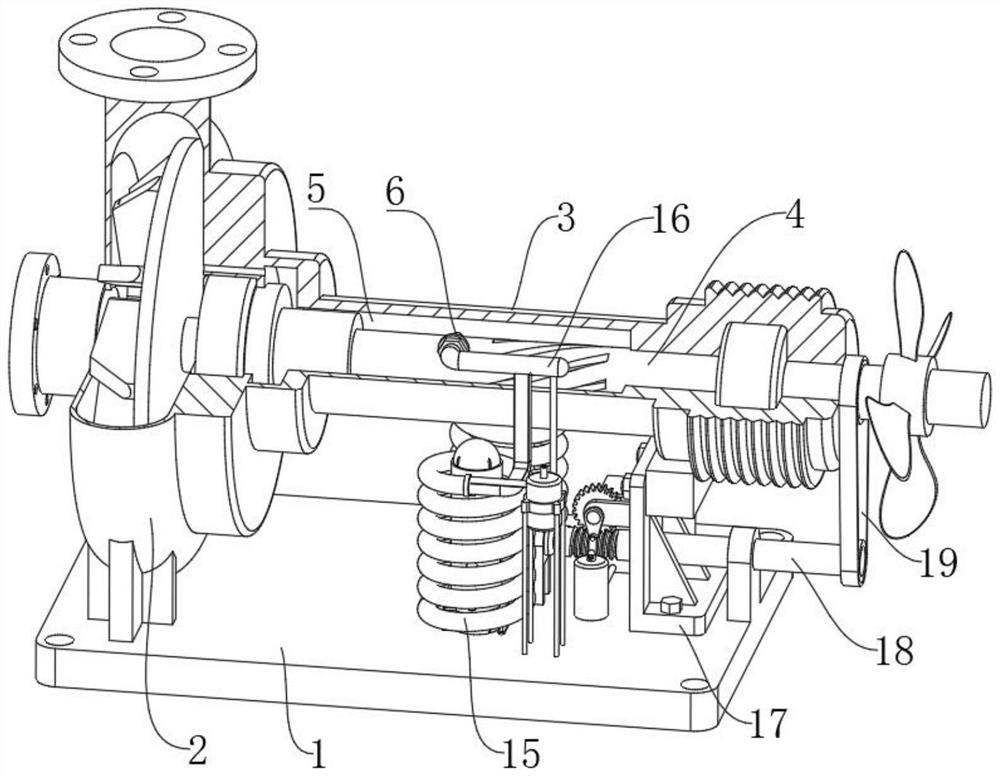

[0033] see figure 1 and figure 2 , a thermal oil pump with an oil-gas multi-stage separation mechanism in the figure, including a base 1, the upper end of the base 1 is fixedly installed with an impeller shell 2 and a sealing sleeve 3, and the impeller shell 2 and the sealing sleeve 3 communicate with each other, and the sealing shaft The inner side of the sleeve 3 is embedded with a transmission shaft 4, and a sleeve cavity 5 is opened between the sealing sleeve 3 and the transmission shaft 4, and fan blades are fixedly installed on the outer surface of the transmission shaft 4, and the sealing sleeve 3 and the base 1 are fixed. Mounting frame 17 is installed, and the front end of sealing shaft sleeve 3 is equipped with connecting pipe one 6, and the rear end of sealing shaft sleeve 3 is equipped with connecting pipe two 7, connecting pipe one 6 and connecting pipe two 7 are all connected with the shaft The casing cavity 5 is connected; the exhaust mechanism 8, which can re...

Embodiment 2

[0044] see Figure 7 In this embodiment, the embodiment 1 is further described. The cooling mechanism 10 includes two sets of fixed columns 39 installed inside the oil guide pipe 15, and the fixed columns 39 are fixedly connected to the base 1, and guide rails are fixedly installed between the two sets of fixed columns 39. Flow pipe 40, seal pipe 57 is installed on the inboard of fixed post 39, and the outside of seal pipe 57 is installed with several groups of one-way valve nozzles 58 through through pipe, and one-way valve nozzle 58 is embedded in the inboard of fixed post 39, and guide tube The two ends of 40 correspond to the bottoms of two groups of sealed pipes 57, and the outside of the guide pipe 40 is equipped with a conveying member 12. Under the action of the conveying member 12, the one-way valve nozzle 58 can spray alcohol solution on the surface of the oil guide pipe 15. , to lower the temperature of the oil inside the sleeve cavity 5 .

[0045] see Figure 7 a...

Embodiment 3

[0049] see Figure 7 and Figure 9 , the implementation mode is further described for other embodiments, the outer side of the fixed column 39 is equipped with a protective piece 13, and the protective piece 13 includes a protective sleeve 55 that is movably socketed on the outer side of the fixed column 39, and the inner wall of the protective sleeve 55 is fixedly installed with a limit strip, And the limit bar and the fixed column 39 are movably fitted, the outer side of the protective cover 55 is provided with several groups of through holes 56, the bottom of the protective cover 55 is fixedly installed with the limit plate 41, and the two sets of limit plates 41 are fixedly installed with a connection Frame 42, the upper end of base 1 is fixedly installed with deceleration disk 53 through the platform, and the input shaft of worm screw 18 and deceleration disk 53 is fixedly connected, and the output end of deceleration disk 53 is fixedly installed with cam 54, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com