Continuous variable speed pressure control method for sub-transonic flutter test

A control method and variable pressure technology, applied in aerodynamic testing, sustainable transportation, testing of machine/structural components, etc., can solve problems such as alarming air consumption, changes in dynamic characteristics of model structures, damage, etc., and achieve stable control methods. , The effect of saving air source and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

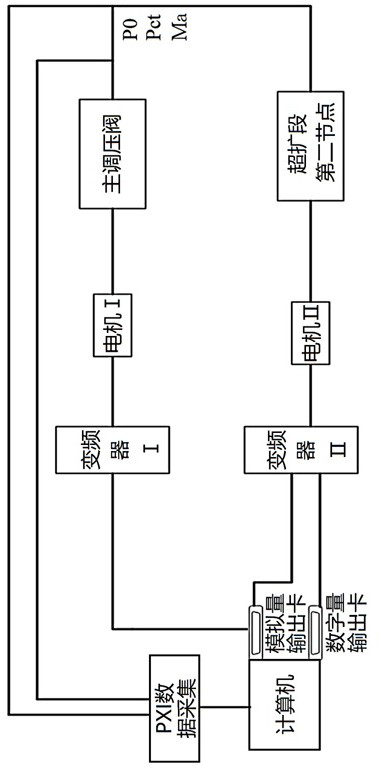

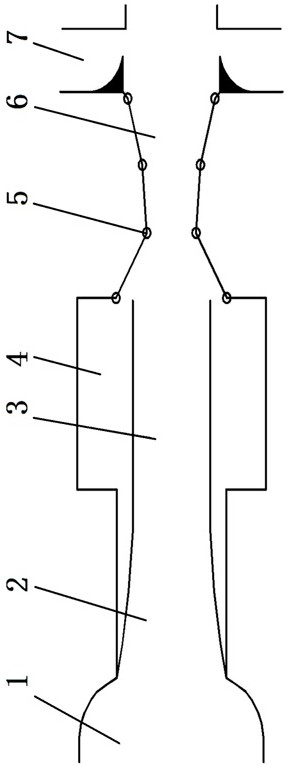

[0058] The test wind tunnel of this embodiment is a 0.6-meter high-speed wind tunnel. The wind tunnel is a three-sonic wind tunnel with temporary downflow of direct current. The cross-sectional size of the test section is 0.6m x 0.6m, the Mach number ranges from 0.4 to 4.5, and the attack angle ranges from -10° to 50°. like figure 2 As shown, the wind tunnel includes an antechamber 1, a test section 3, a supersonic diffusion section 6, and a suction ejector 7 connected sequentially from front to back. The rear end of the front chamber 1 is connected, the rear end of the 0# nozzle 2 is connected to the test section 3, the supersonic diffusion section 6 has four nodes from front to back, and the second node 5 of the super-expansion section is to adjust the cross-sectional area of the second throat key nodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com