Tactic zinc oxide granular one dimension mesoporous nano belt and precursor and its preparing method

A technology of zinc oxide particles and zinc oxide nanometers, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of harsh control conditions, high production costs, and stagnation, and achieve stable product quality, low cost, and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Precursor for preparing mesoporous nanoribbons with oriented zinc oxide particles

[0019] Mix 0.1M zinc acetate aqueous solution with 0.1M hydrazine hydrate or 0.1M ethylenediamine aqueous solution in the same volume, the original clear solution becomes cloudy immediately, after stirring evenly, let it stand at room temperature for 2 hours, a large amount of flocculent After centrifugation, the precipitate was collected and dried to obtain a solid product.

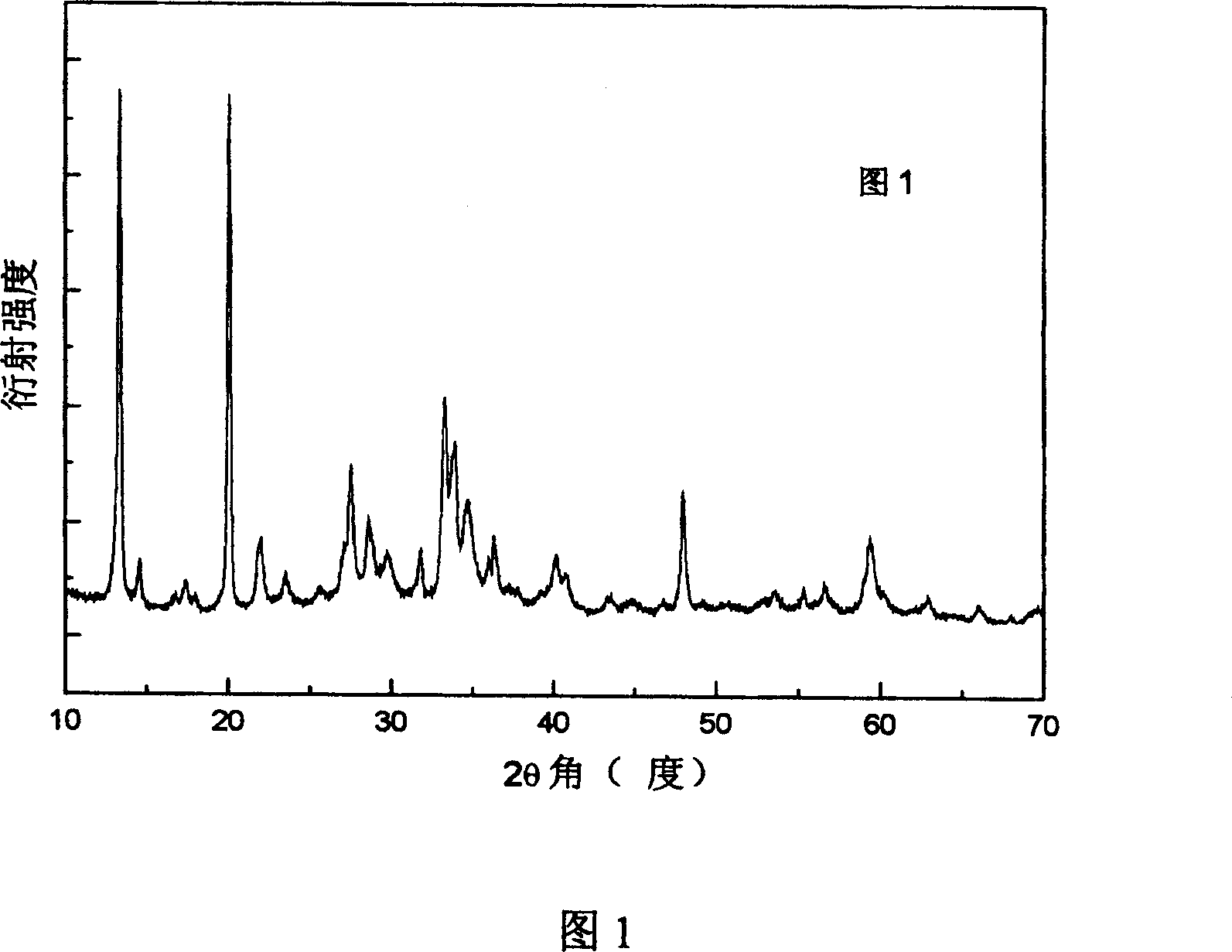

[0020] The structure, chemical composition and morphology of the solid product were characterized by X-ray diffraction, chemical composition analysis and transmission electron microscopy.

[0021] Fig. 1 is the X-ray diffraction pattern of the product of the present embodiment. The abscissa of the spectrum is the 2θ angle, and the ordinate is the relative intensity of diffraction. However, there is no powder diffraction card corresponding to all the diffraction peaks in the spectrum in the JCPDS powder...

Embodiment 2

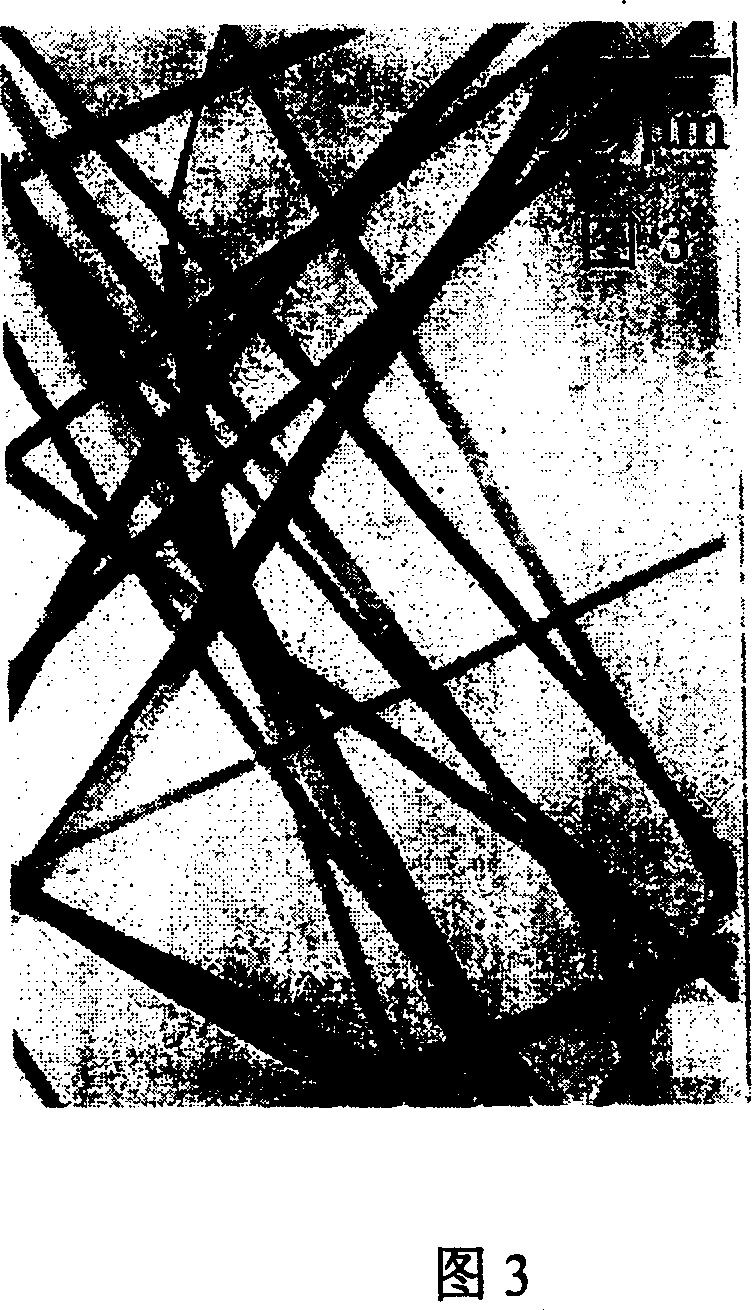

[0026] Example 2: Preparation of one-dimensional mesoporous nanobelts with oriented zinc oxide particles from precursors

[0027] Calcining the precursor of the mesoporous nanoribbons of oriented zinc oxide particles obtained in Example 1 at 700° C. in air for 3 hours, a white solid product can be obtained.

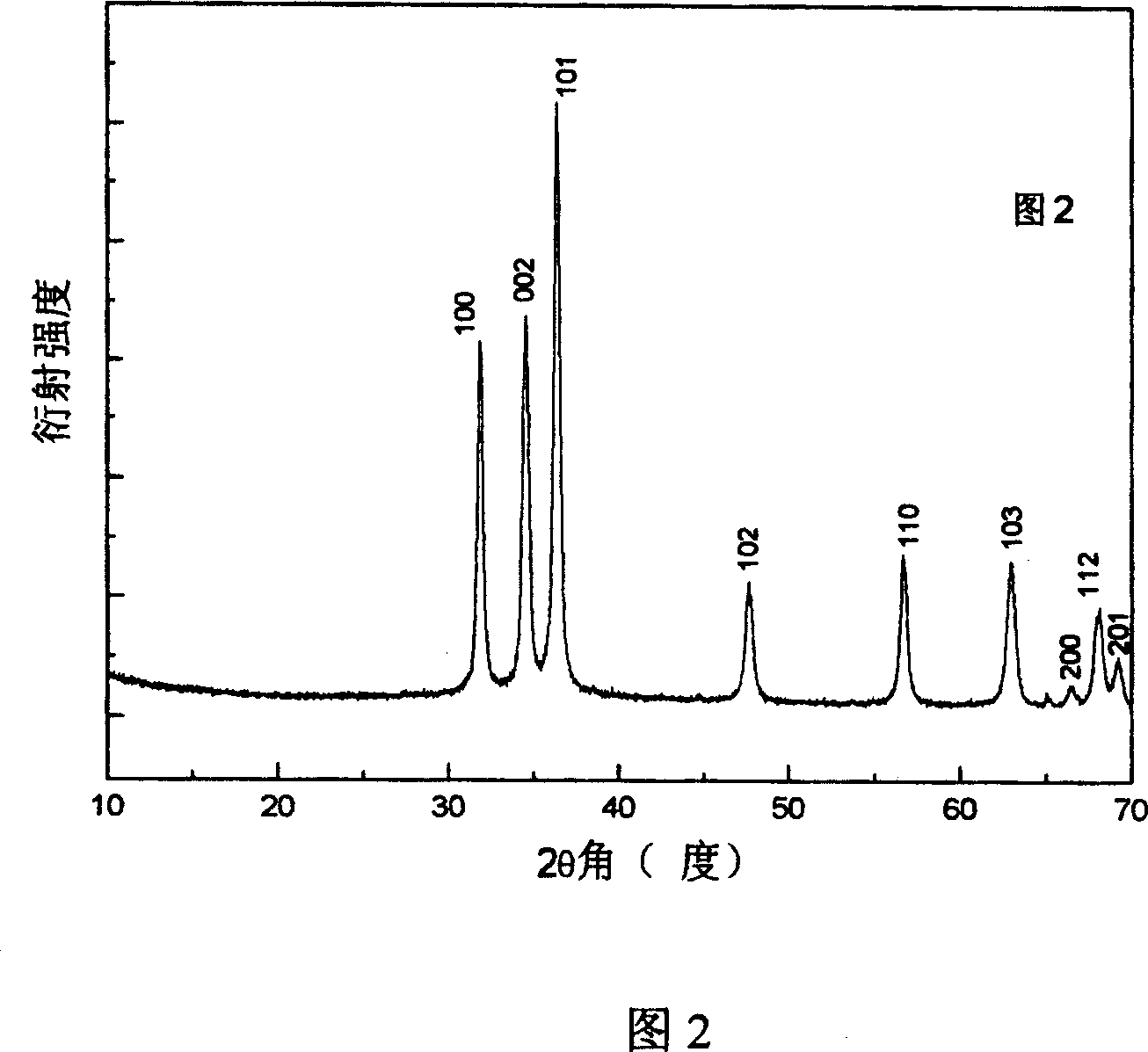

[0028] The structure and morphology of the white solid product were characterized by X-ray diffraction, transmission electron microscopy and electron diffraction:

[0029] Fig. 2 is the X-ray diffraction pattern of the product of this embodiment. The abscissa of the spectrum is the 2θ angle, and the ordinate is the relative intensity of diffraction. Comparing the spectrum with the powder diffraction card JCPDS 01-1136, all the diffraction peaks in the spectrum can correspond to the powder diffraction card JCPDS 01-1136, which proves that the product is hexagonal phase zinc oxide. It can be seen from the spectrum that, except for the diffraction peak of zinc oxide, no ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com