Railway guardrail defect detection method and equipment

A defect detection and guardrail technology, applied in neural learning methods, image data processing, instruments, etc., can solve the problems of high false alarm rate, low integrity of manual judgment, difficult field application, etc., to achieve strong anti-interference and improve detection. Good accuracy and scene generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

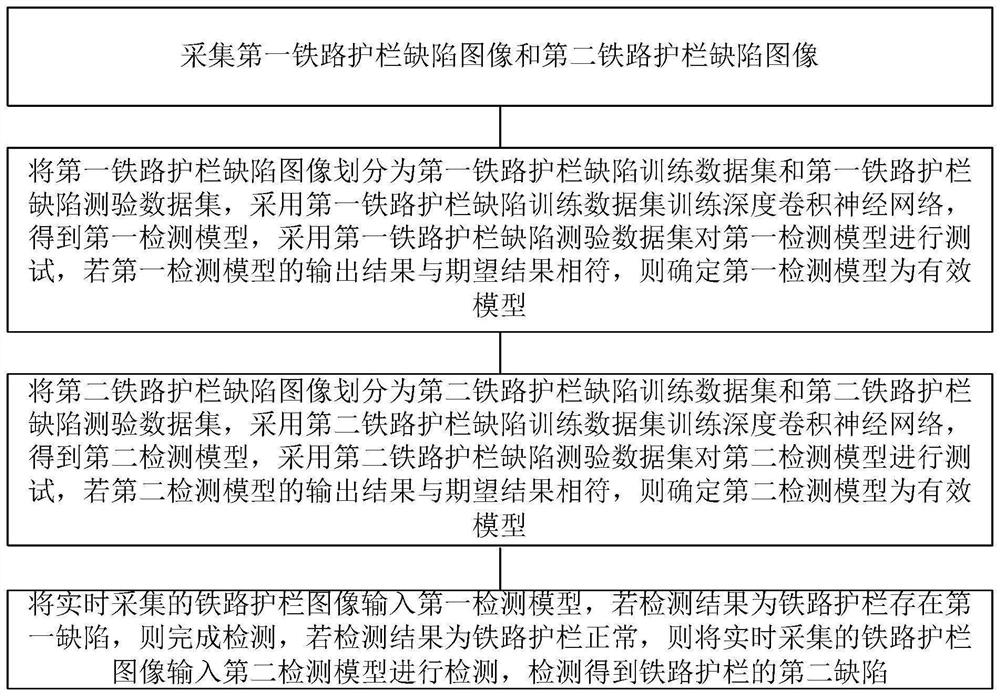

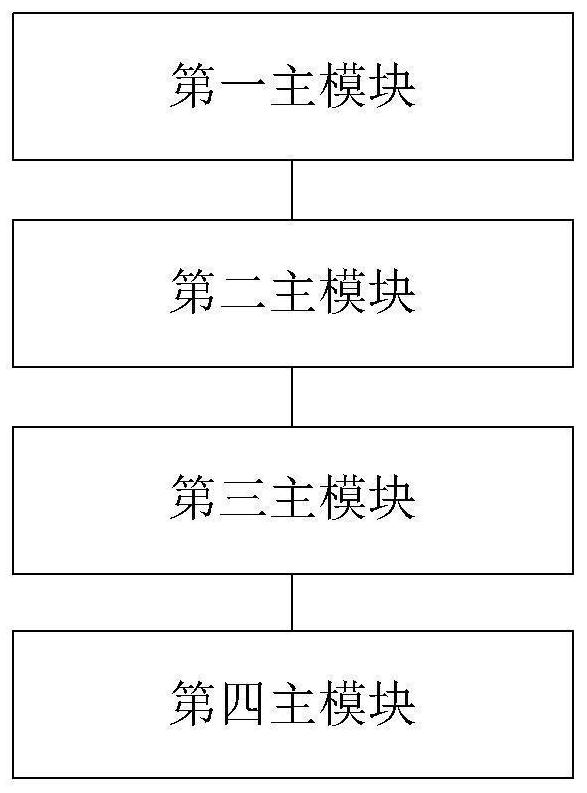

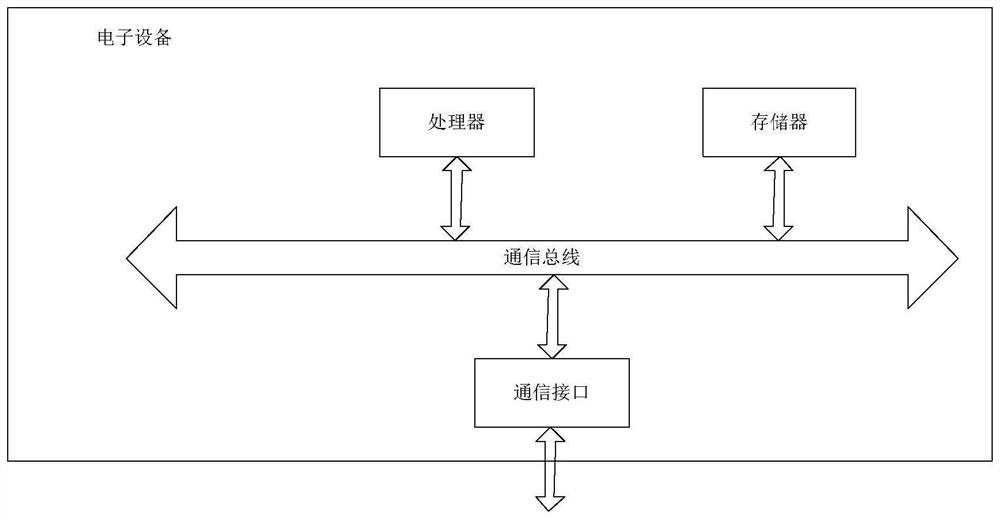

Embodiment Construction

[0025] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments These are some embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention. In addition, the technical features in each embodiment or a single embodiment provided by the present invention can be arbitrarily combined with each other to form a feasible technical solution. This combination is not restricted by the sequence of steps and / or the structural composition mode, but must be in the order of Those of ordi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap